In the three years since we last caught up with Warwickshire-based Hadley Farms, much has changed. The farm has embraced a 93ha solar scheme, which brings security to farm incomes for the next 30 years, enabling the family-run business to continue its journey of expansion.

KEEPING IT BRIEF

- Solar scheme provides guaranteed income.

- Soil biology improving.

- Mixed farming essential to spread risk.

- We first met Rob Hadley in the 4/2008 issue and revisited him in 3/2015 and again in 2/2023.

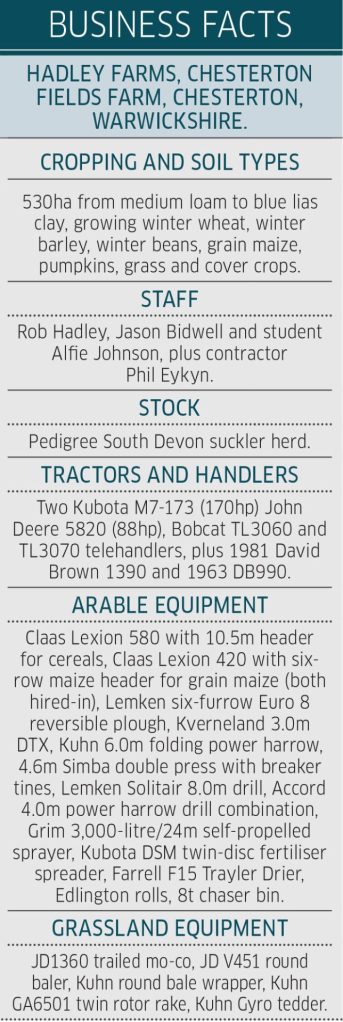

Since Hadley Farms was established in 1984 at Chesterton Fields Farm by John and Jean Hadley, the family farming business has made four land purchases on its journey of expansion. In that time, the farming operation has tripled in size, peaking at around 590ha, supporting the acquisition of land alongside several contract farming agreements.

The most recent investment in land came just two years ago, and comprised two blocks of 80ha and 30ha, some of which the Hadleys had been contract farming for many years.

A different crop

This latest round of investment has been made possible by the introduction of a solar scheme that has taken 93ha of less-favourable land out of production, and in doing so has guaranteed the farm a secure, index-linked income for the next 30 years.

“Our goal has always been to develop and grow our farming activities,” explains Rob Hadley, who runs the farm with his mum Jean, wife Pauline and daughters Francesca and Amelia. “For us to move forward in the current climate, sacrificing 20% of our farm for energy production has enabled us to invest in a similar area of land to maintain our farmed area at a level that can be managed with existing staff and machinery.”

With the Hokey Cokey of land farmed, along with subtle changes in contract farming agreements, that total area has dipped by just 20ha.

“We’re viewing energy production in a similar way to set-aside and other schemes that have previously taken land out of crop production,” he says. “But the crux is, we still want to farm successfully and profitably, and to provide food for the nation. Without the solar payback, buying land would have been nigh-on impossible based on existing farm incomes, and we may have had to make serious sacrifices with labour.”

The flip side of investing in land is dealing with the shadow now cast over the industry through the Government’s inheritance tax rules. Like many other farms, the value of Chesterton Fields Farm has increased through hard work and investment, and the family has recently been engaged in ways of forward planning to manage that risk, following the loss of Rob’s father, John, in 2023.

“Yes, we could have bought insurance to cover Mum with a seven-year policy, but it would have required an eye-watering premium of £7,000/month,” he says. “We’d be four years into paying that premium before it would shift the balance into being cost-effective.

“We’ve taken a lot of advice, and have put plans in place to shift the business into a family trust. Would we have done anything differently if the goal posts hadn’t been moved by the Government?” asks Rob. “Unlikely, as there wouldn’t have been the need to protect our long-term farming future for the next generation of Hadleys to come.”

More mathing

Drawing on knowledge from the Bank of England’s inflation calculator, Rob highlights changes in values that have occurred over the last 40+ years which have influenced the farm’s decision to look into diversification.

“Wheat prices in 1984 were £124/tonne, and according to the Bank of England, they should be up at £407/tonne today,” points out the Warwickshire farmer. “And in 1988 for example, the price of a finished bullock was £800, so today’s price should be more than three times the value they currently are. Purchasing power and profitability, have both been eroded.”

“If those prices were where they should be, I wouldn’t have needed to consider diversification through solar,” says Rob. “But if you do the same as you’ve always done, you’ll get the same as you’ve always had. And the definition of insanity is doing exactly that, but expecting a different result.”

Rob says that the 53MW scheme will create enough energy to power 16,000 homes when it comes fully online in 2026.

Through the construction phase, Chesterton Fields Farm has benefitted from improved farm tracks, as the construction team has created 4.0m-wide tracks to allow safe access for goods vehicles and tipper lorries that have been entering and leaving the two solar site areas. And when the time comes, land will be fully reinstated and drained before being handed back to the farm in 2056.

Evolved farming

“Solar has been the catalyst for restructuring, and the way our farmed area has moved around has made only a marginal difference to farm profitability and efficiency,” he adds. “We are burning less diesel, we’ve eased back on the hours of work and there’s been a reduction in the need for some contractor services.”

This fine-tuning has enabled the family to look closely at its own enterprises. While mixed farming activities will continue to be an integral part of Chesterton Fields Farm, Rob says his 200-strong flock of sheep will be replaced by a larger number of pedigree South Devon cattle, after establishing that the flock was time-negative.

“Adding a dozen or 15 cattle will result in the same meat yield, for little to no additional work,” he says. “We’ll still make around the same number of bales – around 1,500 straw and 1,500 silage – but now feed them to a larger herd, typically 190 head. We might consume more straw, but we create and use all our muck around the farm, so we can keep putting generous levels of organic matter back in the ground. And when we move our cattle to market by trailer, the load value will be higher than a trailer full of sheep – so overall, we’ll be more efficient as a result.”

The farm continues to work in partnership with a local water authority, to store and make the most of liquor from a local AD plant, using a 13,000-tonne lagoon, which also provides the bulk of the farm’s nitrogen requirement. It means there’s no need to buy-in P and K.

Alongside grassland, cropping continues to centre on a mix of winter wheat, winter barley and winter beans, plus grain maize. Stubble turnips, grown for the sheep, are likely to be wrapped up into the arable area, if a local flock doesn’t take advantage of winter grazing opportunities.

An area of pumpkins continues to be grown, and run by Rob’s sister and her husband, which helps with the rotation, and a one-in-five approach is the minimum time period he is prepared to accept.

“Grain maize easily delivered one of our best gross margins in 2025,” he says. “Yield nudged 4.36 tonnes, and given the summer we had, harvest was a joy. It’s the first time we’ve got our grain maize crop off without needing to fit dual wheels to our hired-in Lexion 420 combine which is used solely for grain maize, and it only weighs 11 tonnes.”

Helping hands

He says that the farm continues to enlist the services of local contractor Phil Eykyn for ploughing, and local grower Robbie Armstrong who operates a Challenger MT765 for heavy cultivations. That collaboration means Rob Hadley and operator Jason Bidwell can work with a pair of modestly powered 170hp Kubota M7-173 tractors, keeping costs and depreciation under control.

“Both tractors have been very good, and do all that we need,” he says. “Jason has his favourite out of the two, and has put 4,500 hours on that, while I’ve only got around 1,700 hours on mine.”

The farm’s materials handling requirement has evolved, following prolonged use of two Manitou MLT 627 telescopics that had become increasingly unreliable for the workload.

Not one to follow trends, Rob has a penchant for doing things differently. It may be recalled he swapped a Bargam self-propelled sprayer for a lime-green liveried Grim self-propelled machine supplied by Merse Agriculture, adding technology and future-proofing his crop protection application work.

“I’m still impressed with the Grim GSM3000,” he says. “Cab comfort is good and with the engine positioned right at the back, it’s a very quiet place to sit. The ride is great, and with auto start-stop on the 24m boom’s 13 sections, we’re better off with logistics and application accuracy across the farm. It’s good to try something different.”

And now, he has turned his back on premium telehandlers for what he believes are under-rated machines – that of the Bobcat ilk. After some deliberation over what kit he preferred as replacement machines, the search ended up in Shenington Airfield near Banbury, at local Bobcat dealer Bruce Hopkins’ yard.

“I settled on a two-year old TL3060 Ag-spec machine and a new TL3070 construction spec machine,” he says. “The ag-spec is a three-tonne, 6.0m machine, and the construction model is three-tonne, 7.0m, and the differences between them are minimal.”

The TL3070 is just 75hp, so it avoids the need for complex SCR after-treatment systems fed with a diesel exhaust fluid. The TL3060 packs 106hp, and is dressed with a DPF, DOC and SCR package.

“It’s good to have dodged the AdBlue bullet on one of them,” he says. “It’s less to go wrong and less to give trouble. There’s a touch more lift capacity than the old MLT627’s were around the yard, and both are so much more sure-footed. We haven’t noticed any difference in hydraulic power and boom speed between the two – but I noticed the £27,000 saving compared to buying two similar age, premium brand models.”

He says that for moving bales from field to farm, the ag-spec TL3060 is first choice, given its quicker road speed, air seat, boom suspension and hydraulic trailer hitch.

“A 40km/hr road speed over the construction model’s 30km/hr road speed makes the difference here, so the slower machine stays in the yard ready to unload trailers and stack bales in the barn, while the faster one loads and hauls trailers,” he says. “They are under-rated machines, but well-worth a look, given the cost savings available.”

Both are likely to clock-up around 1,000 hours/year, and the general consensus is the hydrostatic transmissions are far more controllable than torque converter drivelines. “There’s a period of adjustment needed, but once you’re dialled in to the pedals, there’s nothing to touch them for precision placement.”

In addition, Rob has bought a Chinese-made masted forklift truck from cattle breeding pal and engineer Ivan Kendle of North Norfolk Vehicle Solutions. With a three-tonne lift, the diesel-powered forklift adds yet another dimension to yard work across flat concrete surfaces, hinting at the possibility of more diversification to come.

Kit changes aside, the farm has undergone significant transformation in recent years, adapting to survive.

“Farming this acreage of land 40 years ago provided employment for about 24 staff across seven farm holdings, and required six combines,” says Rob. “As a result of commodity prices that just haven’t kept up with inflation, we’ve had to implement economies of scale and adapt to operational efficiency through mechanisation, and we’re now down to the equivalent of two-and-a-half staff and one hired-in combine.”

Summary

Hadley Farms has always stood out as a farming business that thinks a little bit differently to the mainstream. Whether its equipment choices, cropping or diversification, there’s never been a me-too approach from this Warwickshire-based family farm. And sometimes it’s refreshingly good to paddle your own canoe – you just need to find the right stretch of open water to navigate for the long term.

Geoff Ashcroft

For more up-to-date farming news click here and subscribe now to profi and save.