Tracked tractors are purpose-designed for heavy draft work. This we know, but just how much of the power developed by these titans translates into actual tractive effort? And does a continuously variable transmission, now increasingly popular on high-powered wheeled tractors, score points over a powershift transmission on a tracked tractor?

KEEPING IT BRIEF

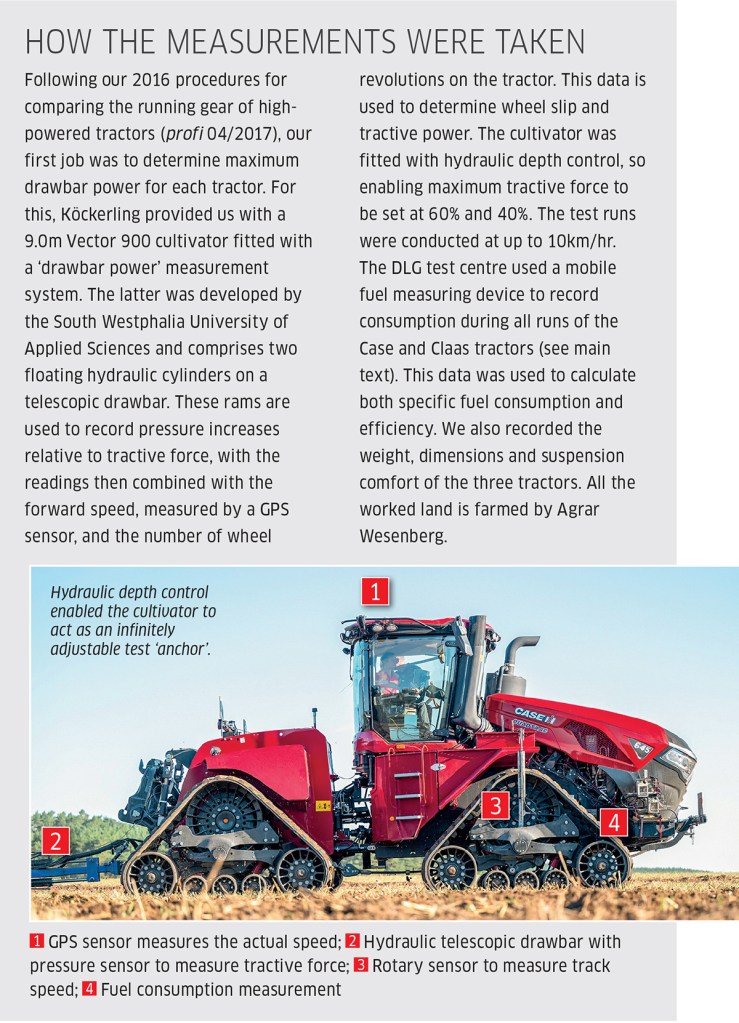

- Three different tractors: 2,265hp total power. Twelve sets of tracks.

- Under 5% of slip for huge tractive effort.

- Light footprint. Heavy weight.

High-horsepower tractors have long held our fascination, but what really counts is how efficiently these big leviathans convert engine power into tractive effort. Here we hope to shed some tester light into the darkness that can surround true efficiency.

The test candidates

- Case IH Quadtrac 645 — 474kW/645hp rated power, 514kW/699hp max power.

- Claas Xerion 12.650 — 450kW/612hp rated power, 480kW/653hp max power.

- John Deere 9RX830 — 610kW/830hp rated power, 672kW/913hp max power.

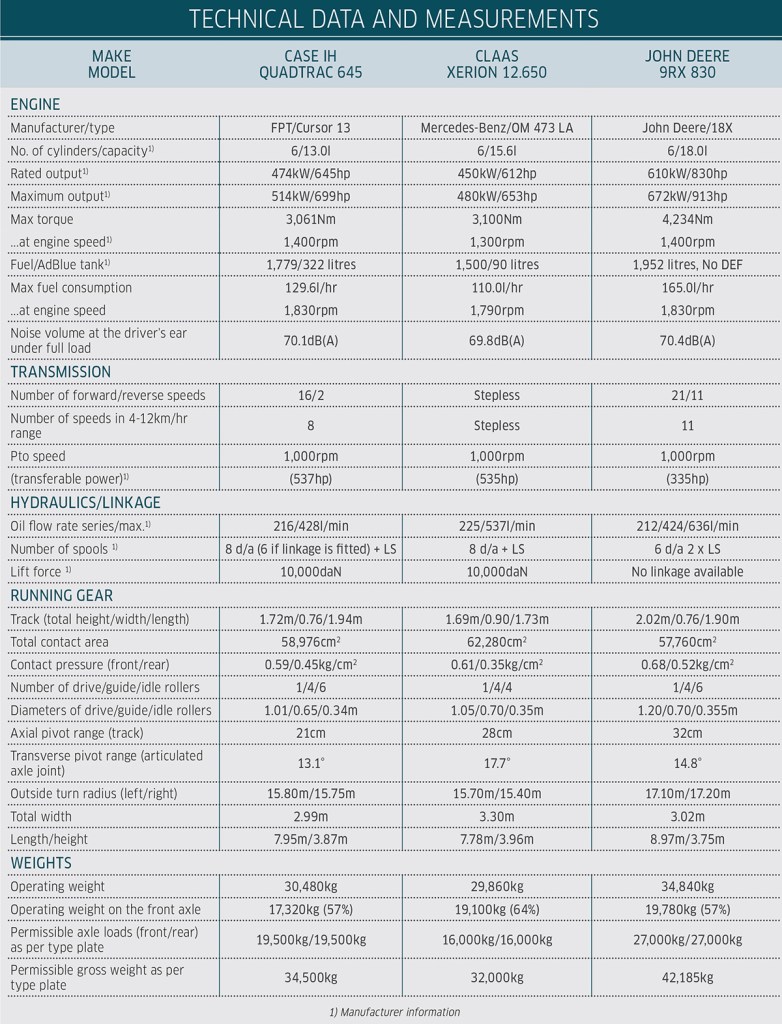

A critical point to note is that we’re not trying to compare apples and oranges here, with clear differences between these tractors in terms of power — see the table ‘Technical data and measurements’ on page 24 for the full ins and outs of the three tractors.

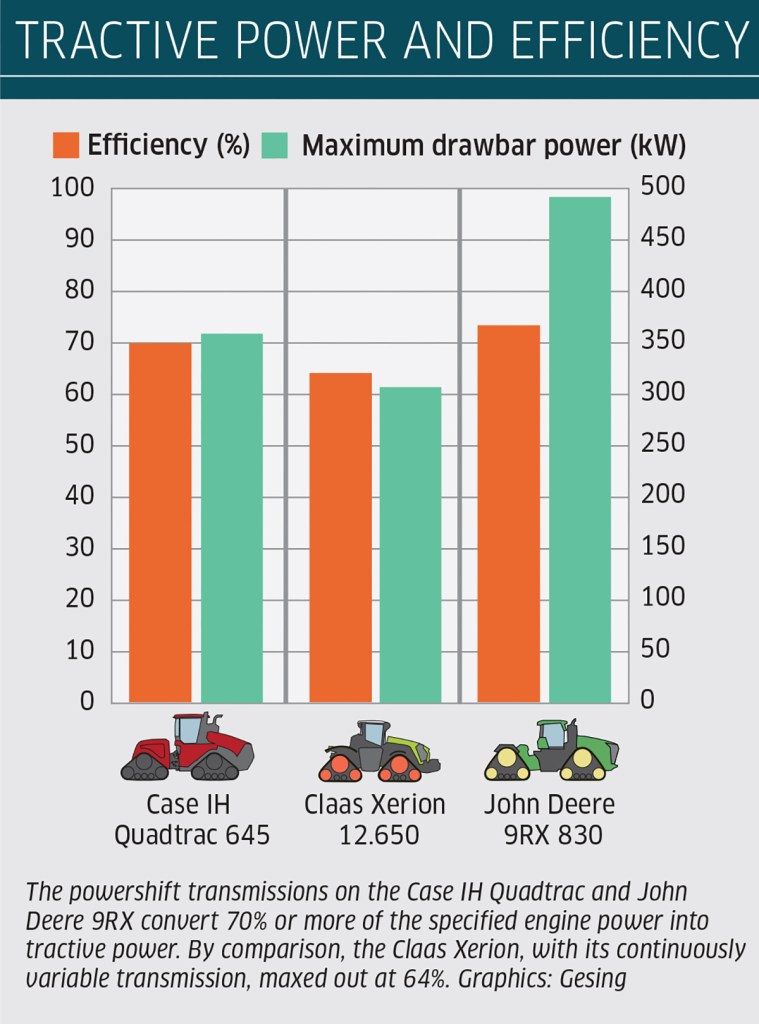

The John Deere 9RX is considerably more powerful than both the Claas and Case IH, for starters. Our approach here is to look at efficiency. What percentage of engine power makes it down to the tracks? Does a powershift have the edge in this class of tractor, or is a CVT the way to go?

Comparing transmissions

As the Quadtrac and Xerion are a far more even match in terms of their engine power, we can realistically and properly compare their transmissions — the Case IH with its powershift and the Claas with a CVT. When it came to getting the tractors together, we turned to arable farmers and contractors Agrar Wesenberg, situated some 120km to the north of Berlin. It was running a new Xerion 12.650 for the first time this past autumn, and they let us use this tractor for these tests. Claas stepped in by providing a Xerion specialist to set up the tractor.

As you would naturally expect, soil type has a major impact on the actual tractive power, a factor that we noted back in 2016 when we last compared the running gear of high-powered tractors.

The soil around Wesenberg is predominantly sandy, which sadly is less than ideal when it comes to measuring full lugging power. A heavy clay soil can prove more ‘grippy’.

That said, a 9.0m wide Köckerling Vector cultivator, kitted out with wing tines and working down to over 35cm, brought all three of our titanic trio to their knees when attempting to run at 10km/hr.

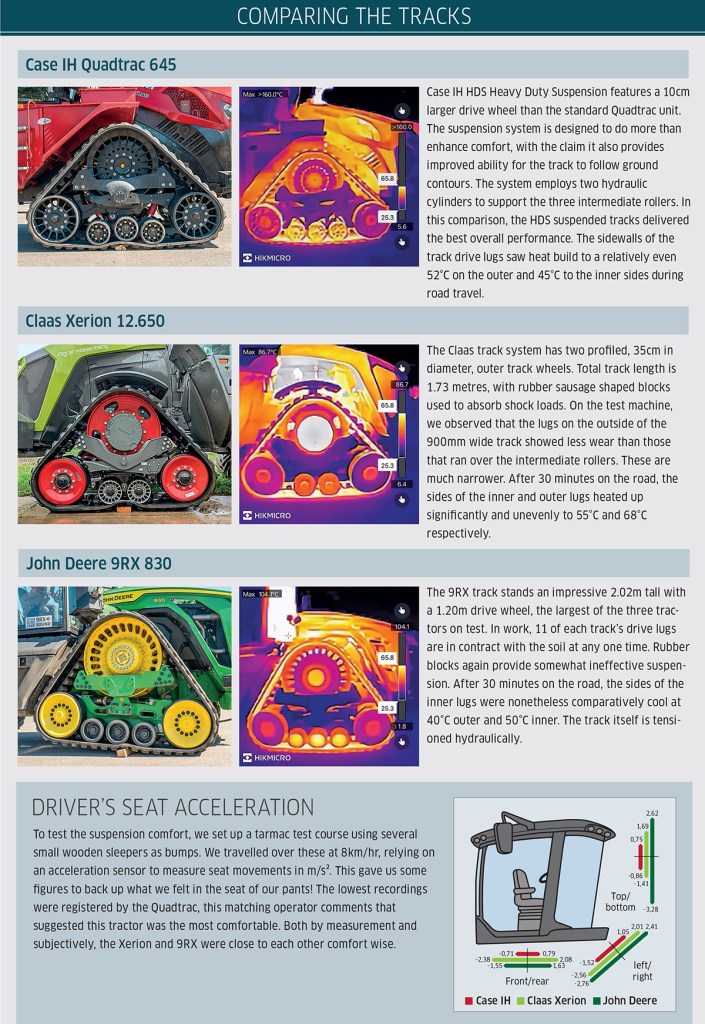

The Xerion was specified by the customer to run on 915mm wide tracks (these are not offered in the UK where you can only have 762mm belts — to keep the width within 3.0m), these delivering a 6.2m² footprint spread across a working width of 3.30m. Both the Case IH and John Deere were clad with 760mm tracks with respective contact areas of 5.7m² and 5.8m². Working width of both was 3.0m.

In work, we found all the tracks gripped and interlocked well with the sandy soil. At full tractive power and running at 10km/hr, we measured 4.0% ‘wheel’ slip on the Quadtrac, 4.6% on the 9RX and 2.0% on the Xerion. Weight distribution on the John Deere 9RX and Case IH Quadtrac was fixed, with 57% of the dead weight resting on the front axles of both tractors when stationary.

Our man from Claas ballasted the Xerion so 64% of the weight rested on the front tracks to optimise traction. Any downsides? On a public road within Germany, permitted axle loads should not exceed 16 tonnes. The Xerion would have significantly exceeded this, weighing in at 19.1 tonnes up front. See our final comments.

Pushing physics to the limit

With a maximum tractive power of no less than 491.8kW/659.5hp, the big John Deere 9RX 830 converts an impressive 73.3% of its specified 671kW/899hp of engine power into tractive effort. In return, it drinks 165 litres of diesel an hour. That may well sound devastating, but when translated to specific fuel consumption it weighs in at 280g/kWh. Thanks to its power class, the 18.0-litre John Deere engine does not need AdBlue, a further point in its favour in terms of RX operating costs.

There is a caveat here, however, and that is that we had to rely on the accuracy of the Deere’s diesel consumption gauge. We cannot vouch for its accuracy. The DLG consumption kit we use simply does not have the capacity to measure fuel use in such large volumes. The fuel consumption measurements for the Quadtrac and the Xerion, in contrast, are based upon DLG verifiable figures.

When developing their maximum tractive power, both the Quadtrac 645 and Xerion 12.650 reached the slip limit, the maximum pulling force they can generate before the tracks slip excessively, at less than 4.0km/hr. The more powerful 9RX reached the slip limit at 7.5km/hr, despite a dead weight of 34 tonnes. This is where the true limits of physics are reached, as even a heavily loaded track will run out of grip at some point.

If more tractive power is called upon, the road legal limit of 31 tonnes total weight for a tracked vehicle would need to be raised. Would this pose a threat to the durability of our roads? You could argue that our test titans only develop a contact pressure of 0.5kg/cm². Compare this to an HGV truck that can exceed 5.0kg/cm². The problem is that soil bearing pressure and overall load are not the same. A heavy tractor is just that. Heavy.

Mechanical or stepless transmission?

The Quadtrac 645 on test featured a 16- forward and two reverse speed powershift transmission. A continuously variable ZF Eccom 6.0 transmission, as installed on the Quadtracs up to the Quadtrac 555, is also available. The Claas Xerion 12.650 has a ZF Eccom 5.5 CVT unit as standard. In this installation, the ZF transmission’s running speed is increased to reduce overall torque loads.

So, then, how do these different transmission types compare? The Case IH Quadtrac 645 can convert 358kW/480hp of its specified maximum 514kW/689hp engine output into tractive power. This is 69.8%. That figure is 5% higher than the Claas Xerion 12.650, where 307kW/411hp, 64% of its maximum of 480kW/643hp, is turned into tractive effort.

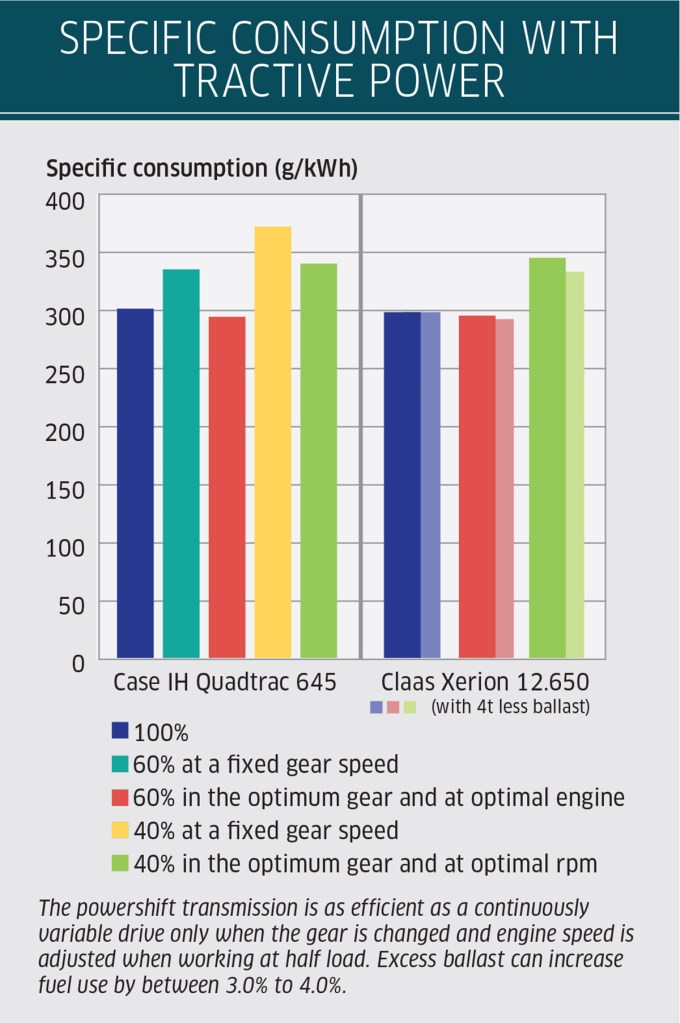

In terms of fuel usage, the Quadtrac 645 consumed 302g/kWh of diesel at a 4.0% wheelslip, this dropping to the equivalent of around 296g/kWh at 2.0% wheelslip. On 900mm tracks, the Xerion’s fuel use in the field was measured at 2.0% wheelslip. Here we recorded consumption figures of exactly 299g/kWh at maximum tractive power. In brief, these two tractors proved virtually on a par in terms of fuel consumption at full load.

Half load efficiency

Matters become more interesting when you tap into the performance figures at half load and in undulating terrain and varying soil types. If, for example, 60% of the max tractive power is required, the Quadtrac 645 driver should shift up the powershift gearbox to reduce the engine speed and with it fuel use. At ‘full throttle’, consumption stands at 336g/kWh. Drop those revs and specific consumption can fade to a more frugal 295g/kWh.

The continuously variable transmission of the Xerion adjusts the transmission ratio and engine speed automatically, reducing fuel use at 60% load down to 296g/kWh. In undulating terrain, where traction is more variable, selecting the correct gear ratio and engine speed is critical if the tractor is to achieve an effective pull. It is here where the stepless transmission of the big Xerion scores. All it takes is for the operator to hit cruise control and the engine-transmission management system takes over to optimise performance.

Although not related to actual performance, another CVT plus that we found was when coupling up to a rear implement where it proved easy to smoothly inch the machine into the best position. Only when lowering the cultivator into the ground did we find it prudent to ease the tractor into work to help the CVT match its engine/ transmission balance to counter the initial spike in load. Claas says it has developed a self-learning software tweak to handle this automatically, but this particular feature was not available on our test tractor.

Both the Quadtrac and Deere 9RX also have automatic shifting to keep the engine within the optimum speed range, but owners and the manufacturer suggest speed shifts are minimised when working at full load. This is simply to spare the transmission clutches from excess wear.

In level going, an operator can select as tall a gear as can be pulled at a fuel sipping engine speed, and under these conditions a powershift can prove to be more efficient than a stepless transmission.

We found that both CVT and powershift transmissions had a higher specific fuel consumption at 40% of maximum drawbar power. There may be a variety of reasons for this, to include excessive dead weight. We put this to the test, as the Claas Xerion could have four tonnes of ballast easily removed. This tweak saw maximum tractive power, due to increased wheel slip, drop slightly to 301kW/403hp; but the specific fuel consumption reduced to 334g/kWh as opposed to 346g/kWh when fully ballasted. This clearly demonstrates it takes energy to move more weight. You need to balance weight and ballast with traction losses, in other words.

Steering concepts

Double-pivot steering is yet another area where the Claas Xerion differed from the two US giants. The Xerion system has two steering cylinders per track, a design that is more involved than the simple articulated joint employed by both the Quadtrac and 9RX. The test Xerion’s manoeuvrability was also compromised by it being fitted with an optional rear linkage. Without the latter, a Xerion will have, according to Claas stats, a turning radius of 15.80m, the Quadtrac achieving a slightly tighter 15.70m.

Road travel

Road transport is something that cannot be overlooked. Apart from weight, fast travel isn’t something that favours a tracked unit, even if the makers suggest a travel speed of 40km/hr is possible.

In our time with these tractors, we found a 30-minute road run was enough to raise the flank temperatures of the inner cleats up to 68°C. Tracks are just not designed for fast road work. There’s the handy option of ‘lubing’ the tracks with talcum powder or sand, this substantially reducing the risk of the rubber vulcanising on the idlers and/or guide rollers during extended fast road runs. But, in practice, we reckon it’s better to just take it easy on the road.

Often too heavy

At a dead weight of 34.8t, a John Deere 9RX 830 crawler exceeds the 31.0t gross agricultural vehicle weight that prevails in the UK. Both the Quadtrac 645 and Xerion 12.650 ‘only’ weigh around 30 tonnes.

Summary

Although manufacturers have yet to reach the boundaries of tractive power, we must be nearly there in practical terms simply due to tractor size and weight. With over 900hp under the hood, the John Deere 9RX 830 demonstrates a big machine can deliver impressive overall efficiency, with 492kW of tractive power matched to 280g/kWh fuel consumption.

The comparison of a powershift and CVT transmission is also interesting, the former having a slight edge in even conditions. The CVT variable transmission is better suited to varying loads where its clever automatic adjustment of the transmission and engine speeds can save on fuel.

As for ride comfort, the Case HDS system was the best. But for further details you’ll need to read the second part of our test.

Tobias Bensing, Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.