Telehandlers are growing in capacity and reach as businesses look to get more from these versatile machines. While 6.00m to 7.00m telehandlers are still the biggest sellers, there’s a noticeable shift towards higher capacity machines with the 9.00m reach handler becoming increasingly popular according to Merlo’s Andy Collier.

With greater capacity and size also comes more horsepower; a CVT-type rather than hydrostatic transmission can be an option to take advantage of this, giving added torque. Another option is a powershift transmission which could be useful for road work and towing.

For work such as stacking straw or potato boxes, lift capacity is also on the up – Merlo has a 9.00m machine which can lift 6.5 tonnes and others are in a similar position.

“Here you are looking at applications which might also be carried out with a loading shovel,” comments Andy. “Capable of taking a 3,500kg or 4,500kg capacity bucket, this machine could also be useful for stockpiling.”

In some operations, a high-capacity telehandler can be a better bet than a loading shovel, offering greater versatility without having to add attachments such as a grain pusher for example to achieve the desired reach, he says.

“With a telehandler, there’s also the option to tow which can be useful at busy times.”

Claas product specialist Michael Ives agrees: “I have examples of large chassis machines working in woodchips and sawdust through to large AD plants where they need to move large amounts of material but need the reach of a telehandler rather than using a wheel loader.”

Andy Collier suggests that purchasers look carefully at the reach envelope of machines under consideration.

“Are you wanting to lift to height or do you also need forward reach? If the telehandler is to be used for work such as placing bales or bags in the back of a barn, capacity at maximum reach is an important consideration.”

Telehandler prices are another talking point and most manufacturers offer a range of spec packages, so check the options match the job in hand. Claas has gone a step further and now offers a ‘despecced’ model: the Pro package combines the most-sold options. The standard spec comes with a mechanical instead of hydraulic locking headstock and omits belly plates, pick up hitch and brakes as well as the usual reversing fan.

Michael adds: “This has enabled us to offer a telehandler as a second/third machine where the customer doesn’t need all of the options which or where it will not be used for towing, for example. The dealer staff can now tailor a machine to exactly what the customer needs rather than having a one fixed specification.”

Jane Carley

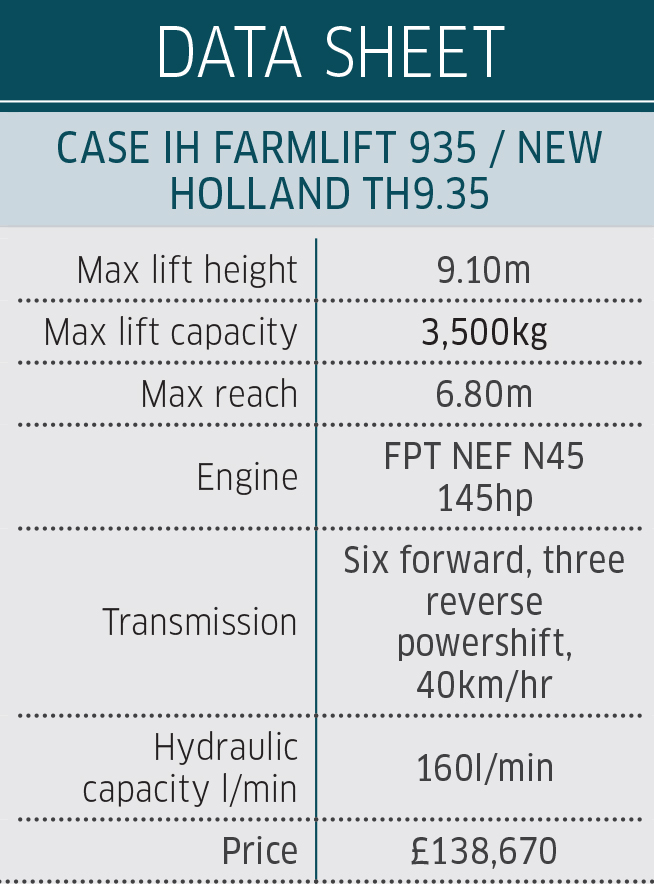

CASE IH/NEW HOLLAND

The latest generation of CNH handlers has improved visibility all around, due to the revised cab position and new bonnet shape. All operational buttons and functions are now part of the integrated joystick/armrest for improved comfort and ergonomics.

The new dash features an interactive screen that can be adjusted through an encoder on the armrest, to set many of the machine’s programmable functions and display from an integrated rear view camera.

A full powershift transmission offers Manual, Semi-Auto and Full Auto modes and the engine and coolers are fitted with reversing fans for work in dusty environments. Specification includes hydraulic hitch and brakes for transport work with a 20 tonne towing capacity.

A 160l/min pump is specified for high hydraulic output and there are also ‘Smart’ hydraulic functions to assist the operator, ie. allowing more power to be diverted to transmission when working on a clamp. Hydraulic power management ensures constant hydraulic power for high resistance pushing or digging, along with forklift mode, bucket shake, and adjustable boom responsiveness.

An automatic levelling system preplaces the compensation ram for easier operation while a longer stronger chassis negates the need for extra counterweight. Along with boom suspension, these features are said to make it an ideal workhorse for bale carting and stacking.

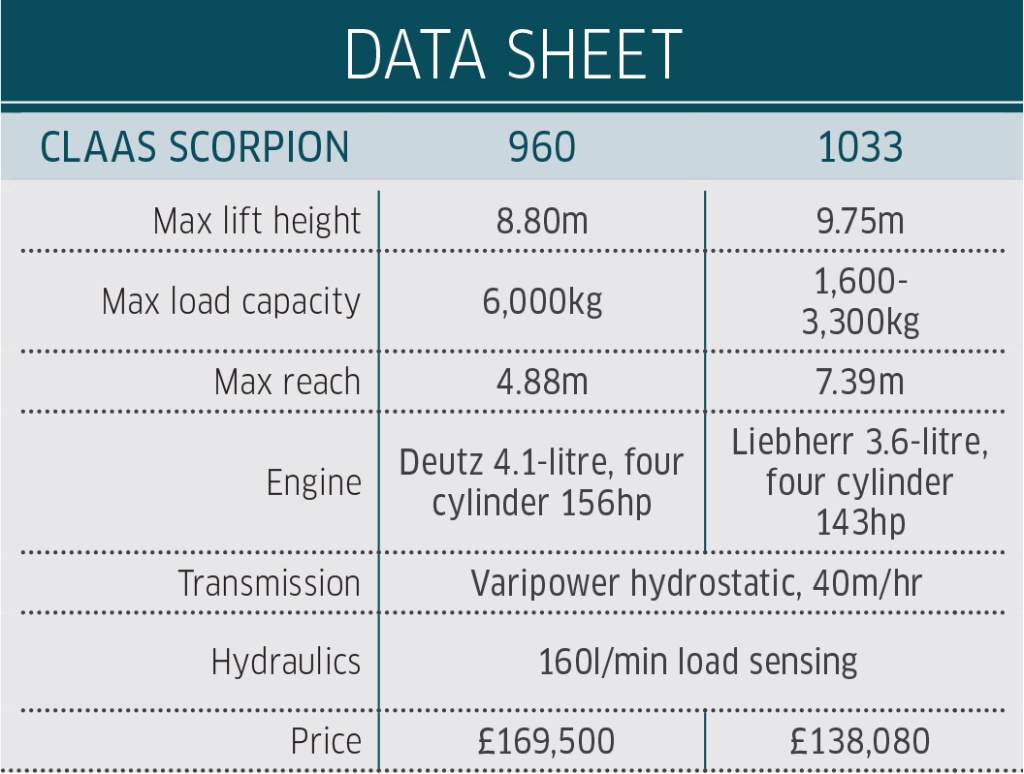

CLAAS

The Scorpion 1033 comes into this category at 9.75m while the Scorpion 960 has a pivot point of 8.8m.

Both the 960 and 1033 offer hydraulic chassis levelling as standard with a hydraulic ram on the pivoting front axle allowing the operator to level the machine up before lifting to height. Above a certain height it locks so that the machine can’t swing from side to side with the boom up.

Varipower hydrostatic transmission is specified for additional control when working at slow speeds.

Product specialist, Michael Ives explains: “The 1033 is more for lighter-duty applications such as straw or stacking boxes or pallets up high. We have one customer who has built special tall buildings so that the bottom is a tipping bunker for his concentrates for the dairy cattle and then he stacks items such as bulk bags or pallets beyond them using the machine’s reach. The Scorpion 960 is an example of the large chassis (sometimes called wide-body) machines, a heavy duty solution for large material movements.”

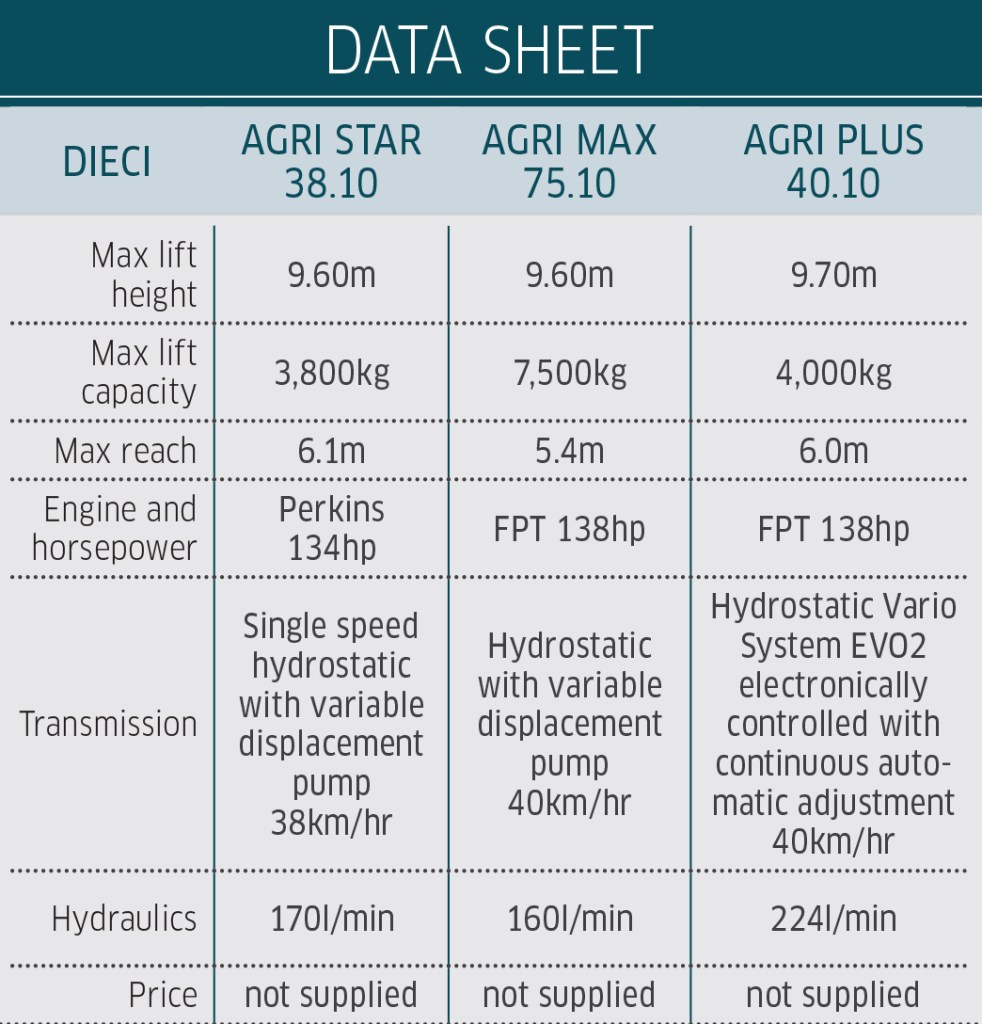

DIECI

Within the Dieci agricultural range, the Agri Star 38.10, Agri Max 75.10, and Agri Plus 40.10 offer lifting heights up to 9.70 m and capacities of 3,800 kg, 7,500 kg, and 4,000 kg.

The Agri Star 38.10 is aimed at livestock farms and mixed agricultural operations. It features a single-speed hydrostatic transmission and an electronic throttle and inching pedal for precise positioning tasks. The Giugiaro Design cab has Zero Shock suspension system for improved comfort and vibration reduction. An electronically controlled boom suspension enhances stability during travel with heavy loads.

Designed for demanding, continuous operations, such as biomass handling, bale stacking, and heavy material movement, the Agri Max 75.10 uses a two-speed electronic transmission. Advanced boom functions in include bucket shake, a ‘Wall’ function for perfect vertical alignment on slopes and memory function to store and recall working positions. The cab offers a 7in display and electro-proportional joystick.

Topping out the range, the Agri Plus 40.10 is designed as a multi-purpose telehandler, utilising a Vario System transmission with four driving modes plus cruise control and gear lock for safety and ease on long or difficult routes.

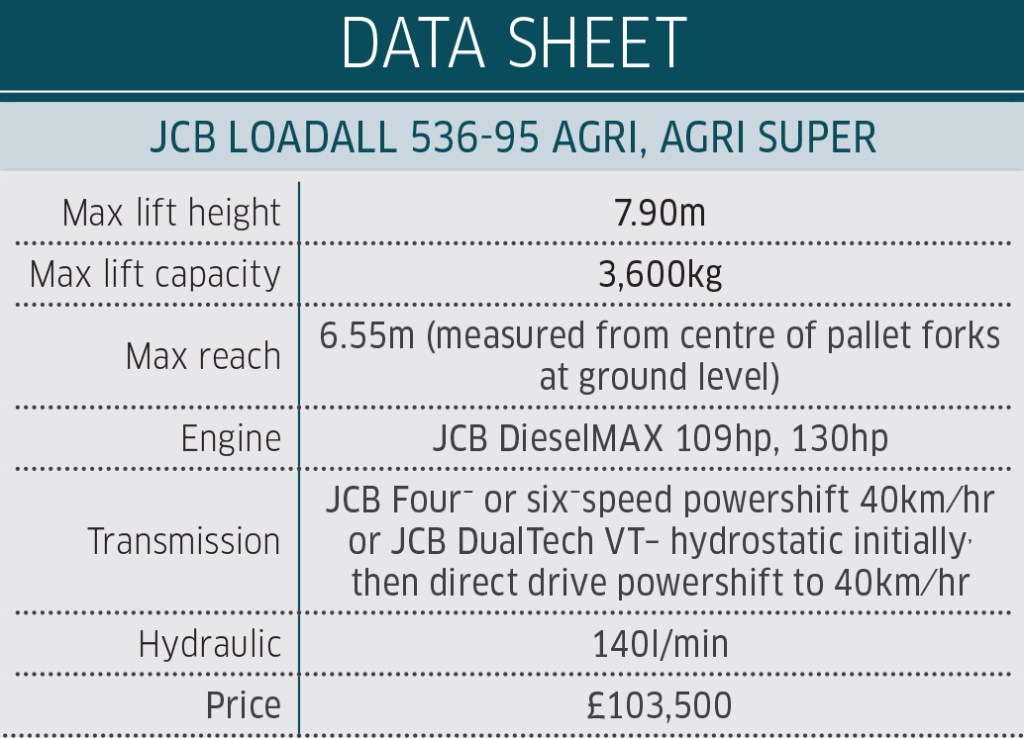

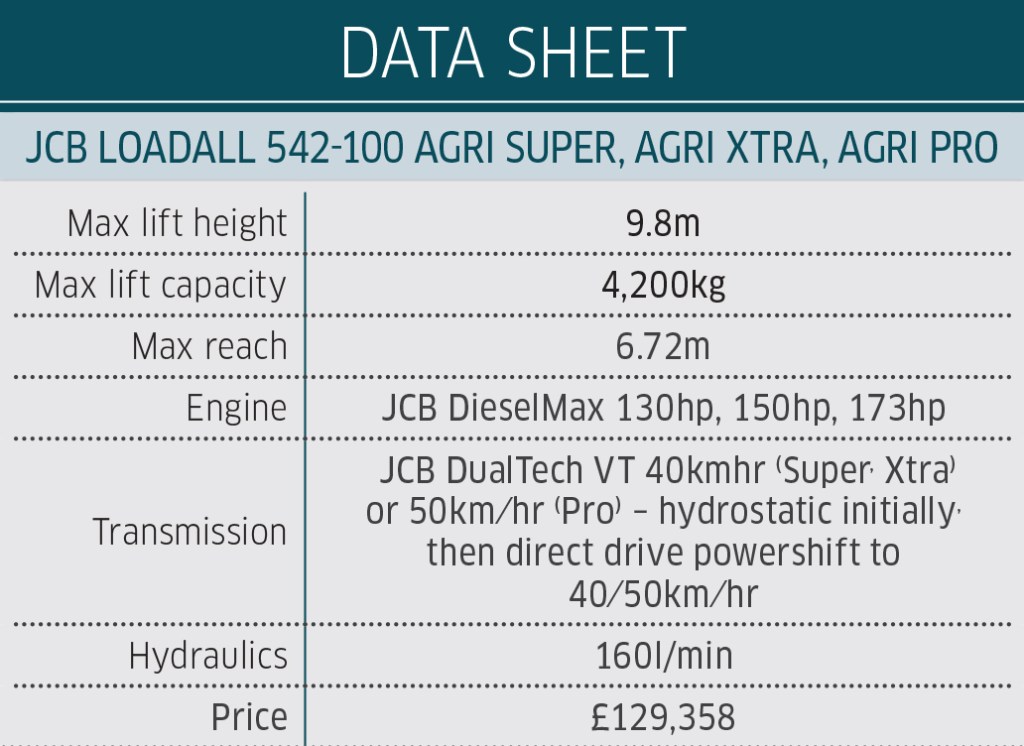

JCB

Latest addition to JCB’s range of high capacity telehandlers is the premium Loadall 542-100 with a maximum load capacity of 4.20t and 9.80m lift height, both significant gains over the current 536-95 but with no increase in overall size.

JCB Agriculture managing director, John Smith, said: “JCB’s Loadall 536-95 handler is a popular choice for large farms and straw contractors but with Loadall 542-100 we now offer a premium high-lift machine delivering increased performance across the board, especially with the Agri Pro version with its greater engine power and faster travel speed.”

Features include a three-section boom and a choice of specifications – the 130hp AGRI Super, 150hp Agri Xtra, and 173hp AGRI Pro. All versions have the JCB DualTech

VT combined hydrostatic/powershift transmission which provides initial movement by hydrostatic drive for the most precise control before automatically switching to direct-drive powershift at faster field and road speeds for maximum power and fuel efficiency.

Sway Control chassis-to-axle levelling is available on Agri Xtra and Agri Pro versions, said to be ideal for placing big bales into large stacks or storage barns as it keeps the boom vertical on sloping or uneven ground.

High-capacity hydraulics use a 160l/min flow-on-demand pump and a regenerative circuit that allows the boom to be brought down rapidly but under full control for fast bale stacking and retrieval cycles.

The 536-95 continues in production in Agri guise with JCB’s manual four-speed TorqueLock4 transmission, and to Agri Super specification with four-speed manual powershift, six-speed auto powershift or a 40km/hr JCB DualTech VT part-hydrostatic, part-powershift transmission.

Both models can be specified with new IntelliAssist, an optional suite of automated boom and attachment functions, and other user assistance features, that simplify and reduce the operator workload.

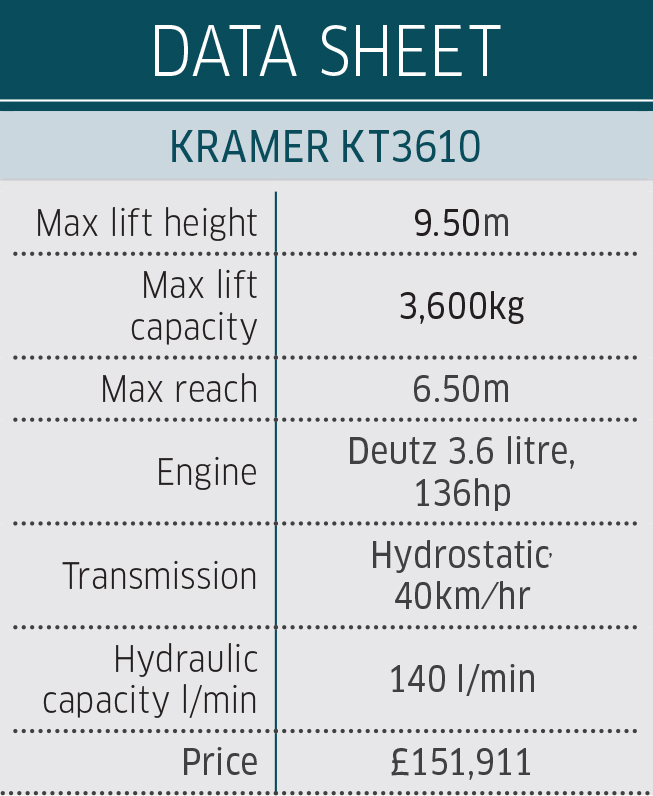

KRAMER

Designed as a compact machine, the KT3610 is just 5.03m long and 2.28m wide, using a three-stage boom to lift to 9.5m. There is a choice of two cab heights with a minimum of 2.31m It features a variable hydrostatic transmission with brake-inch pedal and jog dial system. A Smart Handling driver assistance system with overload protection helps to boost productivity.

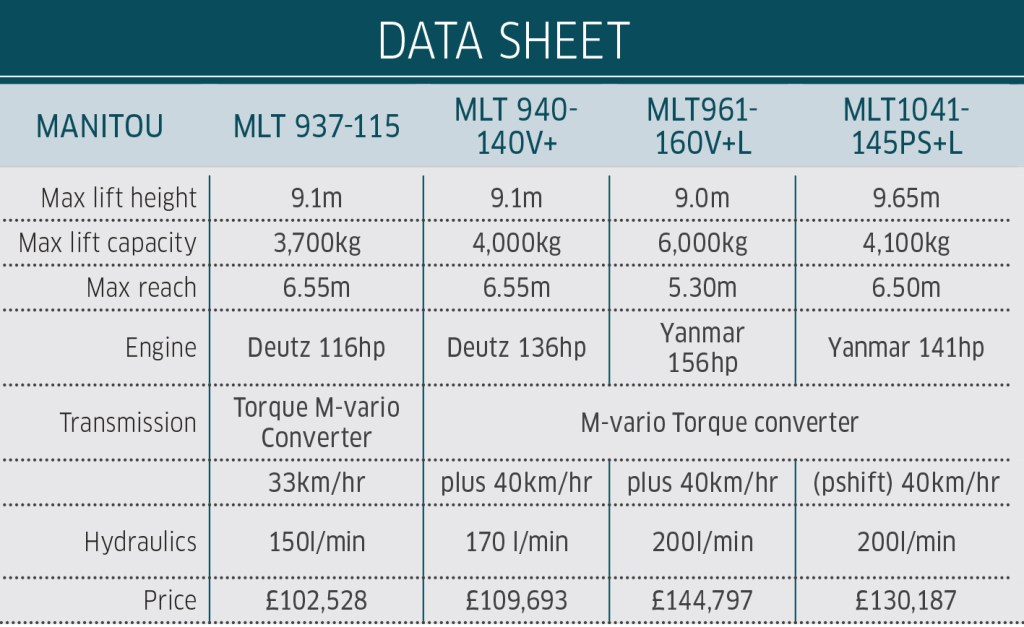

MANITOU

At 156 hp and 805 Nm torque at 1,350 rpm (MLT 961) and 141 hp and 602 Nm torque at 1,500 rpm (MLT 1041) Manitou’s high capacity machines offer power and torque for maximum productivity.

Transmissions are the M-Vario Plus CVT which uses two hydraulic motors powered by a hydraulic pump for a combination of precision and performance, offering smooth driving and the 5-speed M-Shift gearbox, equipped with torque converter, designed to increase traction force and reduce fuel consumption.

At 200 L/min hydraulic flow with flow-sharing technology cycle times are reduced as regenerative hydraulics use gravity to lower the boom faster and save fuel. Features include Quick Lift, bucket shake and return to load.

Handling is improved by high ground clearance and frame levelling ±7° for stability on uneven terrain.

Cab specification includes Manitou’s Comfort Steering System (CSS) to reduce steering effort and the JSM Joystick with armrest for single-hand control of all movements.

A front cut-out section in the windshield further improves visibility when changing attachments, while the curved, heated rear window enhances the view of trailers and surroundings in all weather conditions.

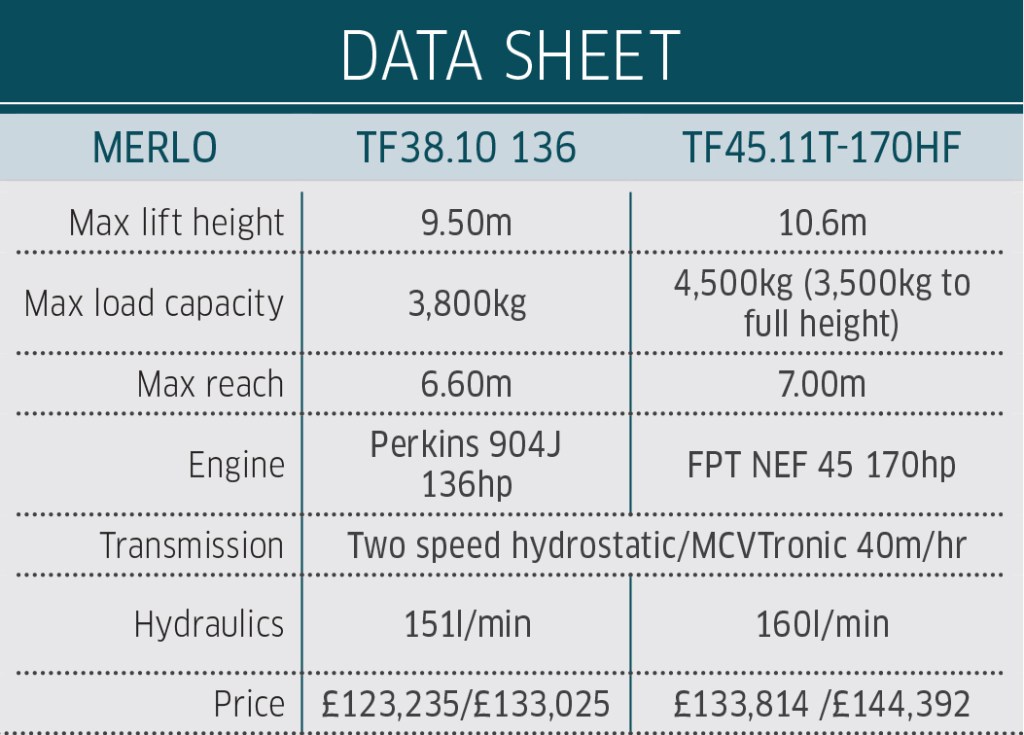

MERLO

A number of options are available from Merlo with 9m lift height, including the Merlo Multifarmer which offers tractor-like versatility with a full pto system and 7000kg rear linkage.

The most popular model is the TF 38.10, which can lift to 9.5m and has maximum capacity of 3.8 tonnes.

An option is boom side shift and frame levelling, which improves performance when placing materials or stacking, product specialist Andrew Collier explains:

“The front axle is connected to the boom via three rams which can tilt to the left and right for improved performance and this levelling also extends the scope of the load chart. It can correct up to 6.0˚ inclines so it increases the load to maximum height.”

“The side shift frame moves the boom to the left or right, avoiding the need to move the machine for fine adjustment of positioning, which also boosts safety.”

Both models are also available with CVT transmissions, he points out.

“This offers shifting from high to low automatically and gives more torque for road work.”

WACKER NEUSON

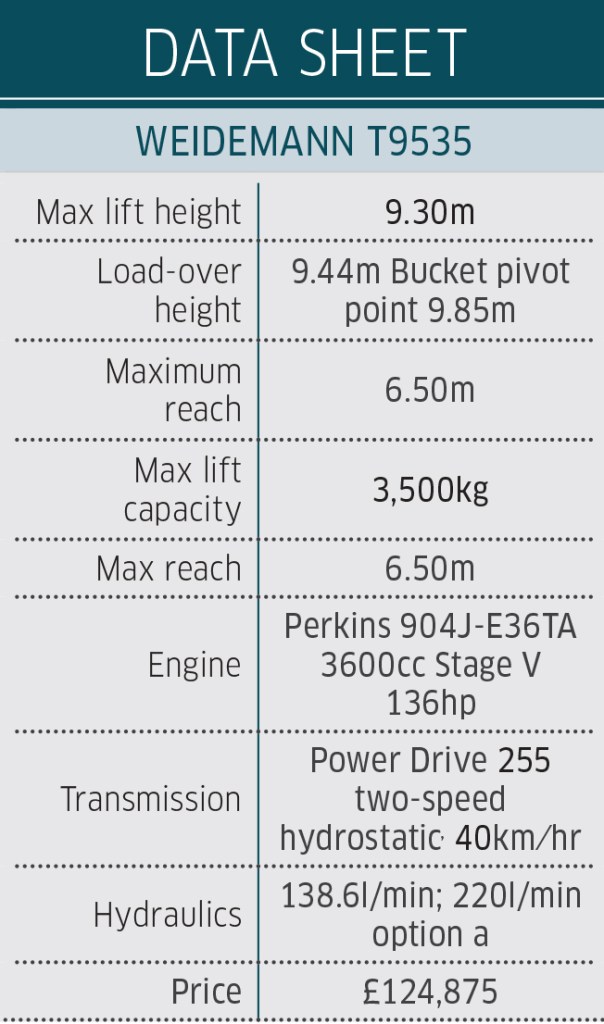

The Weidemann T9535 has a 2.95m wheelbase for increased stability during loading and uses a two-stage boom extension to reach up to 9.85m at the pivot point.

Power Drive 255 transmission is a variable hydrostatic system that is designed to give more pushing power and stepless driving speed; an inch pedal reduces forward speed and diverts power to the hydraulics. Trailer coupling options allow up to 16 tonnes to be towed and standard spec includes hydraulic attachment coupling.

In the ‘Best View’ four pillar cab, the steering column is offset 30mm to the left for an improved working position; features include auto air conditioning and the ‘jog dial’ operating button which allows easy selection of machine parameters and functions.

For more up-to-date farming news click here and subscribe now to profi and save.