The DSX no-till drill accounts for roughly two thirds of the 400+ Horizon

machines delivered so far. We’ve been to see where it is made.

KEEPING IT BRIEF

- Horizon was founded in 2019. George Sly is the sole shareholder

- DSX accounts for two-thirds of the over 400 Horizon machines sold to date

- 2025 turnover is expected to be around £12 million

- With more than 25 global dealers (six in the UK), Horizon has importers in Austria, Australia, Bulgaria, Czech Republic, Denmark, France, Italy, Kazakhstan, Poland, Romania, Moldavia, the Netherlands, New Zealand, Norway, Switzerland and Ukraine.

- A high percentage of new DSXs go out with all the options.

- It takes four days to build a DSX and there is currently a five-month delivery time for new machines.

- Prototypes and pre-production machines are tested on the 300ha family farm where cereals have been direct drilled since 2017 and sugar beet and maize strip tilled since 2010

The Lincolnshire-based company has come a long way since founder George Sly made the first no-till drill in the farm workshop in 2019. What started out as a company manufacturing machinery for the local UK market, has grown in a very short time to a business that sells its products to more than 35 countries around the world.

Horizon founder is George Sly who has several years of agricultural engineering experience as well as being involved with regenerative farming. He set up Horizon after selling a company he had founded in France and set out to build a new generation, low-disturbance drill – the first trailed DSX drills were ready for the spring 2020. Today, the DSX Gen 3 is available in rigid widths of 3.0m and 4.0m; and folding 4.0m, 4.8m, 5.0m, 6.0m, 7.2m, 7.5m, 8.0m and 9.0m variants.

These trailed machines were recently joined by the MDSX mounted models. Previewed at Agritechnica 2023, the baby in the current range is a rigid 3.0m model. Plus, there are six folding models; 4.0m, 5.0m, 6.0m, and freshly-launched 7.5m, 8.0m and 9.0m versions.

The Lincolnshire facility also builds the SPX strip-till cultivator, PPX precision planter, FT2200 (2,200l) front tank and GH400 (400l) granular hopper, but the focus here is with the DSX and we joined managing director, Ed Perry and Matt Miller from the marketing department for a tour of the site.

The bread winner

Produced year round, the DSX is the flagship product to leave Sutton St James. The majority end up on the opposite side of the North Sea which has the same short spring and longer autumn drilling season as the UK.

Germany is a big market as is Eastern Europe, and particularly Romania and Bulgaria. “These countries are very interested in regenerative farming in the dry conditions,” says Ed.

The popularity of the DSX quickly became apparent during our tour of the site, with numerous machines at different stages in the assembly process. All important components are sourced from East Anglia, and all welding (including the frames, wings and drawbar) is done locally.

“We do not have a state-of-the-art factory,” comments Ed, “but what we do have is a highly-motivated nearly 50-strong team. We sell a premium product that not only has to perform well but also look good and last a long time.”

Dressed to impress

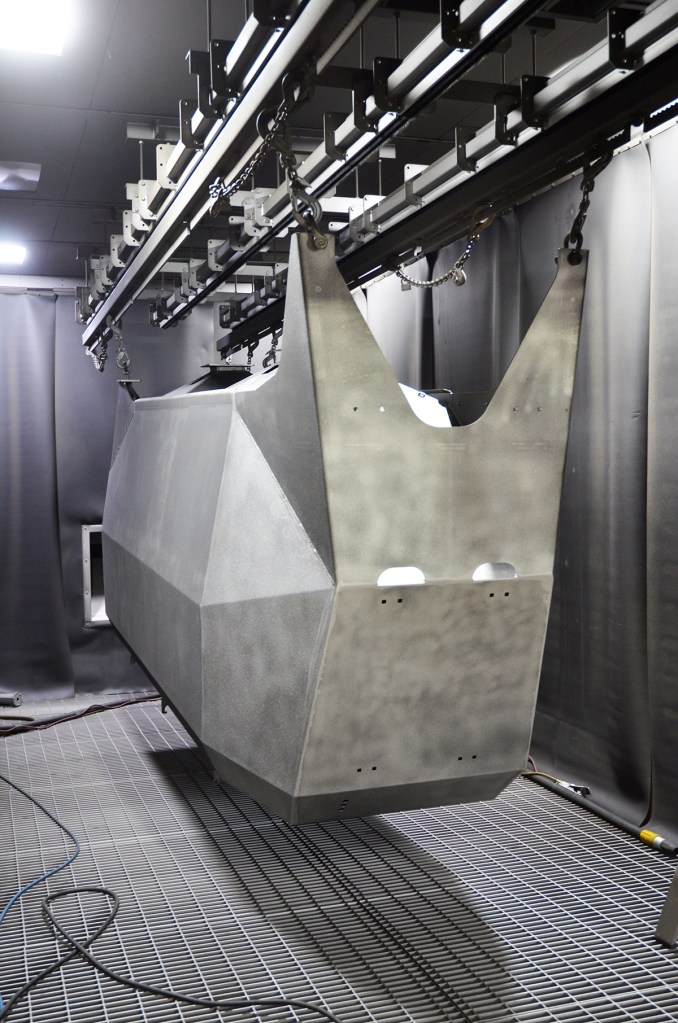

The paint shop plays a crucial role here. Commissioned in January 2020, the purpose-built semi-automatic blasting and coating facility is one of the most interesting parts of the production process. Smaller items go straight into the shot blasting cabinet, whereas larger ones, spend two to three hours in the larger booth.

Commissioned at the same time as the paint shop, the main assembly building provides just enough space to build three of the wider trailed machines at the same time. With two new gantry cranes, it is here that the main- and side frames are pieced together, while three Gen 3 row units are assembled at the same time on jigs.

Still growing

Horizon has experienced rapid growth over the last five years, and while 2024 was a quieter year for the company, this year they will achieve a record turnover over £12 million. “We have bounced back in a huge way this year, and have sold twice as many DSX drills this season than in 2024.”

The new managing director joined Horizon in November 2024 to allow George Sly to take more of a back seat role. Having previously headed up the operation and production at Claydon, Ed was then general sales manager for Case IH at Ernest Doe for 10 years.

The new man in charge is confident that Horizon turnover can grow 20% a year in the next two years. “This will come from increased production of the current portfolio of machines with new widths, and also from new and wider models.”

Production at the current site is nearing full capacity, and with growth forecasts in mind, the company has acquired a 26-acre greenfield site to build a new factory. The new site will have dealer training facilities, a test field, and the capacity to house more spare parts. With planning permission in place, the new facility is expected to be operational by 2028.

Steven Vale For more up-to-date farming news click here and subscribe now to profi and save.