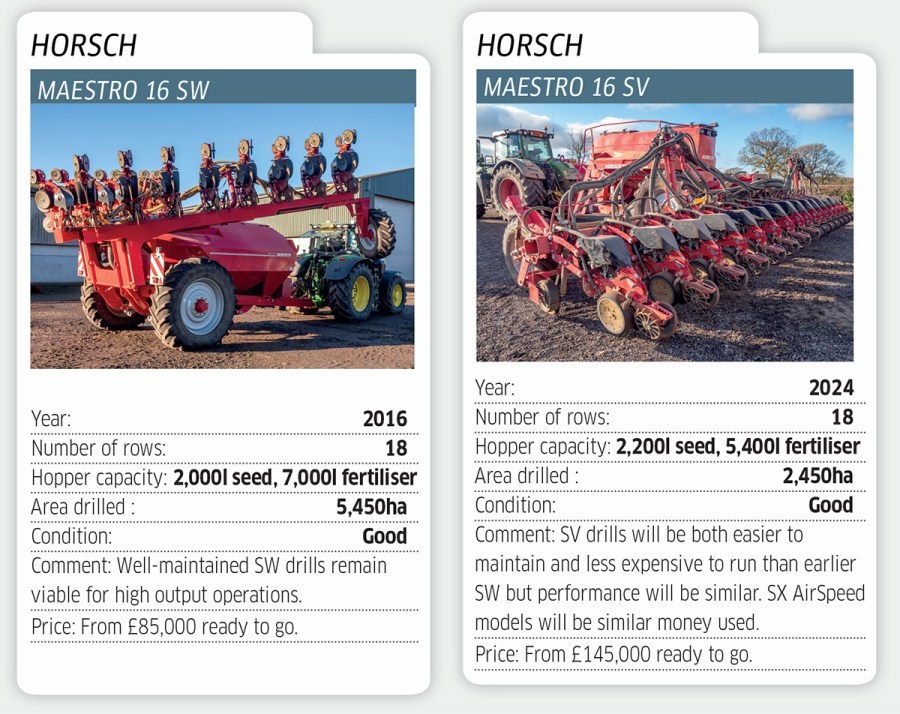

Horsch launched its Maestro precision ‘single grain’ planters back in 2011, trailed SW models with a choice of 12-, 16-, 18- or 24-rows were available by the time these started to arrive in the UK. Fast forward to 2021, and the current SV and SX variants arrived with completely revised metering units, new hoppers and wide changes to the related hardware.

KEEPING IT BRIEF

- Maestro metering units are fitted to both trailed and mounted models

- Soil wearing metal is common to the original and current AirVac and AirSpeed Maestro variants

- Fertiliser coulters can mount separately on current models

- Concentrate on condition. A high hectare count is to be expected

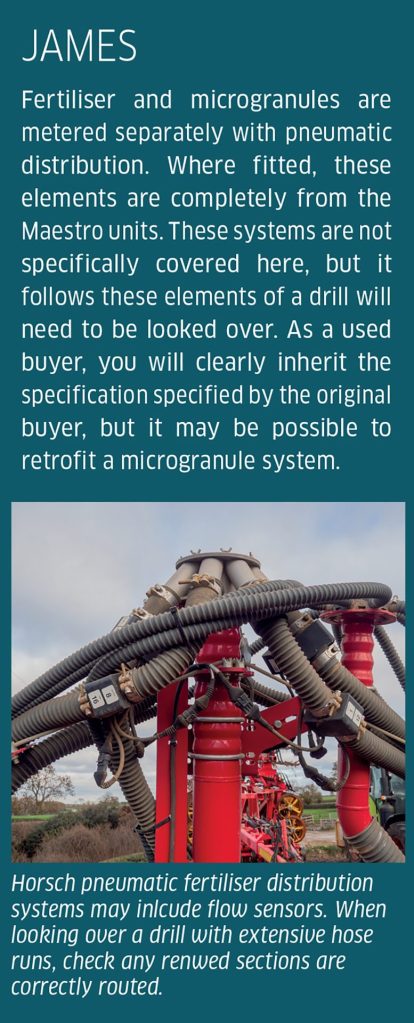

Horsch uses its Maestro seed only precision metering units across a wide variety of planters. It’s the letters after the Maestro name that will give you a better inkling of the fertiliser system (granular, liquid or micro-fert) employed and the configuration of the folding system and it if is a mounted or trailed machine.

As a bit of a broad-brush overview, this is what you are looking at:

- SW and current SV/SX range with 12- and 16-row models at 75cm spacing and 18- or 24-rows variants spaced at 50cm.

- CC 8.75 and CC 12.50m are smaller trailed machines

- RC 8.75m or 12.50m are mounted were subsequently offered.

- Later alternatives to the SV/SX include 45cm to 80cm row adjustable

- TX6 or TX 7 are a type, and entered production in 202?

- RV/RX drills are 6.75m, 8.75m, 9.75 m and 12.50m wide and used a front-mounted fertiliser hopper.

- Smaller trailed CV/CX 8-, 9- or 12-row drills at 50cm spacing or 9 -and 12-row variants at 75cm spacing. Even within the SW and current SV / SX range there are 12- and 16-row models at 75cm spacing and 18- or 24-rows variants spaced at 50cm.

One Maestro family name, but one that includes numerous models to include both toolbar and trailed variants.To simplify matters, here we take a broad look at the first-generation SW and subsequent SV/SX trailed models, the latter offering either AirVac or AirSpeed metering respectively; more on this later. We are aware that there will not be many used SW or later models on offer in the UK and even more so in Ireland, but all Maestro models share essentially the same metering systems.

One of the key features of these drills is the use of an independent electric motor to drive the metering disc of each seeder unit. At launch, much was made of the low current draw of these individual motors. This enabled up to 24 metering units to be run on a single drill without the risk of overloading the tractors electronics.

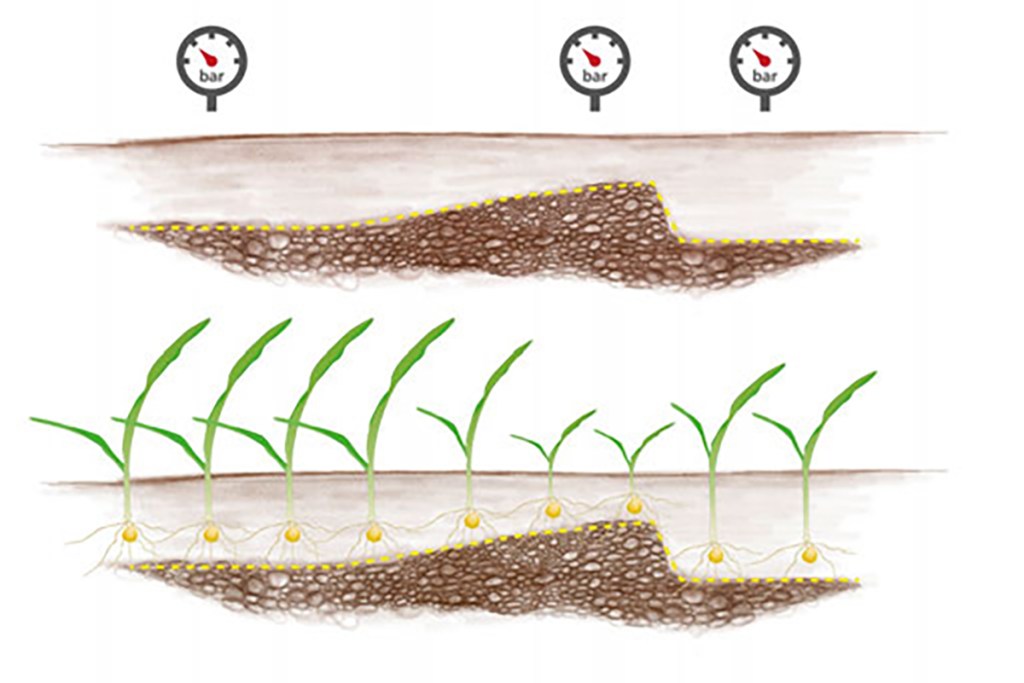

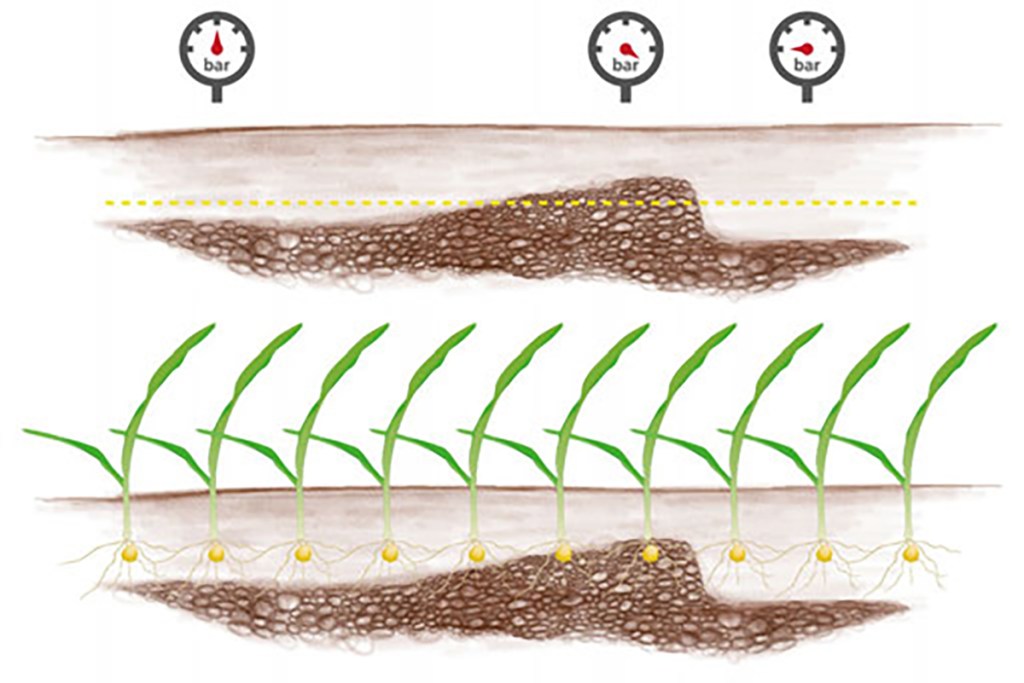

A further design feature is the depth control system that automatically adjusts the seed coulter pressure to compensate for changing soil types and conditions. This system, which Horsch calls AutoForce, is claimed to deliver accurate depth control across the drilling width and along the rows for consistent germination.

First generation SW metering units

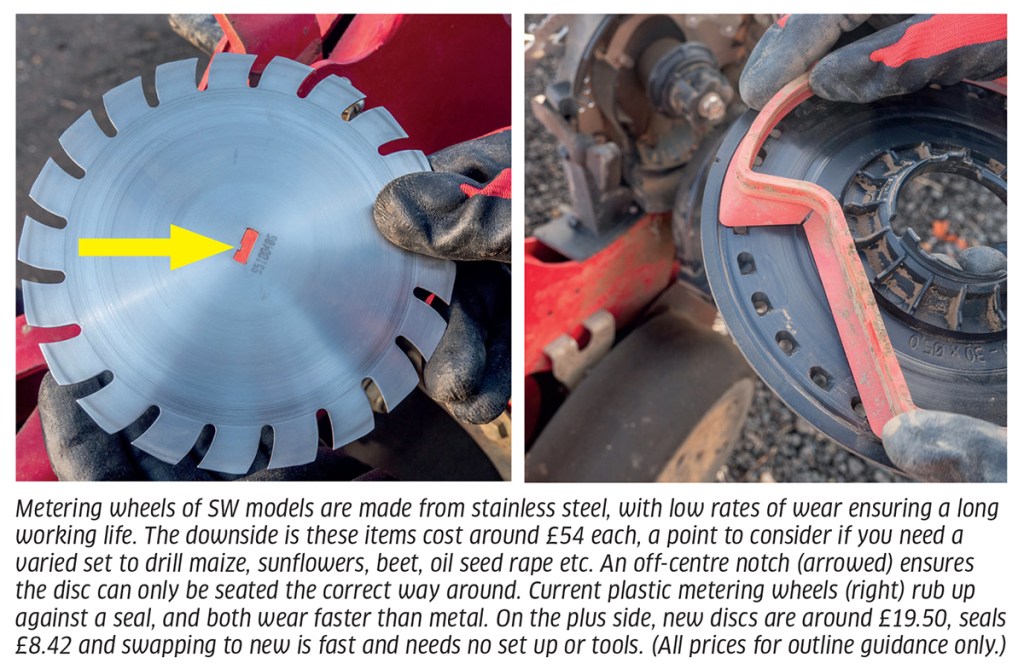

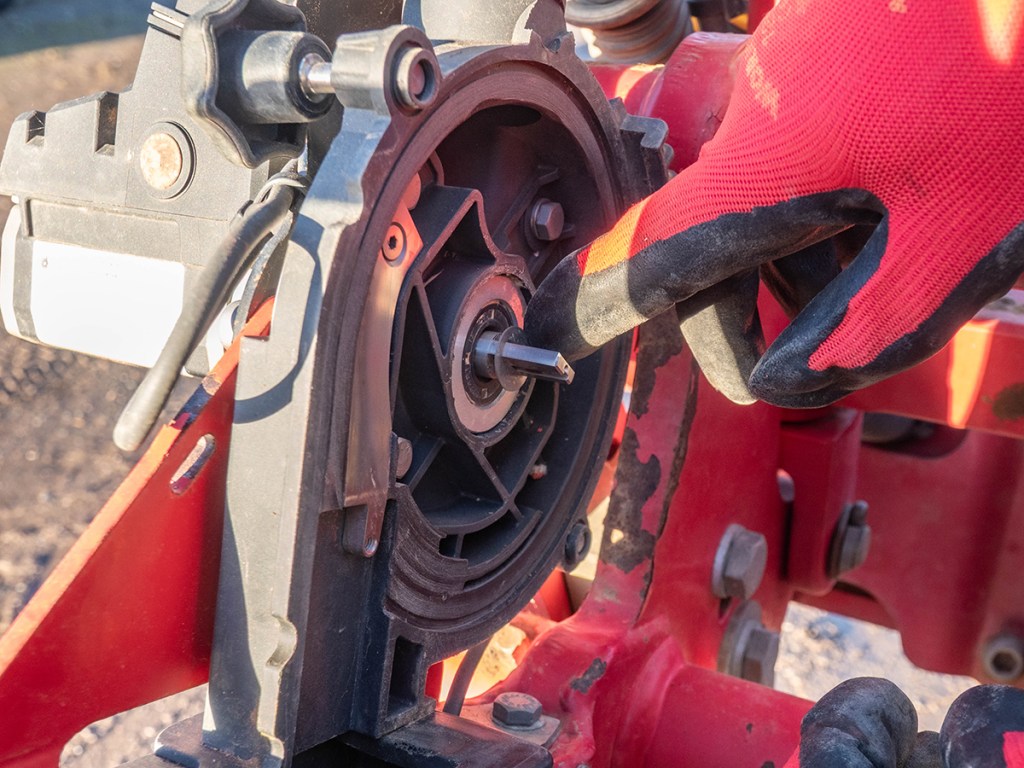

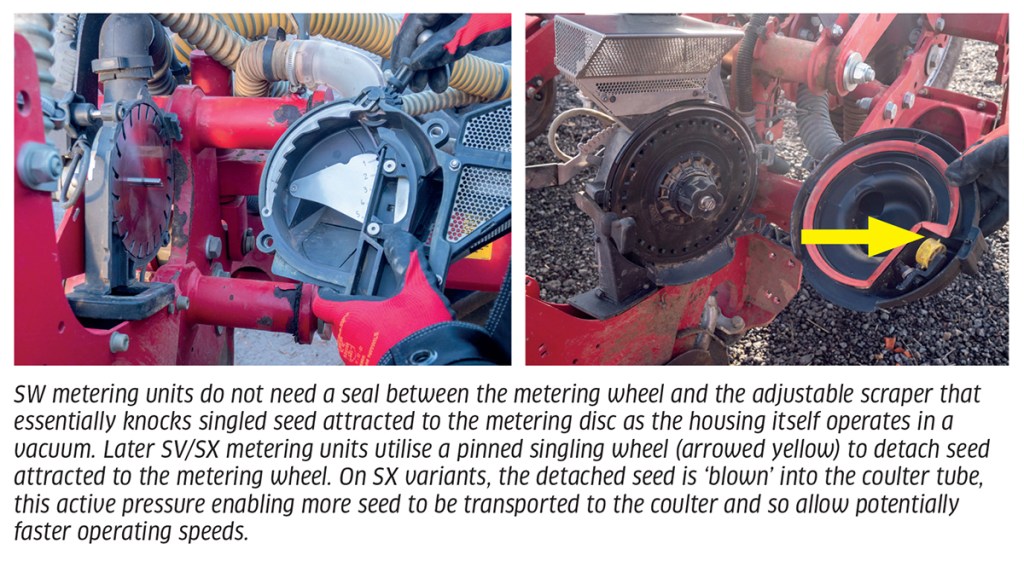

On the SW drills, the metering unit motor has an integral controller that ensures the drive maintains a consistent seed rate at varying forward speeds and across the working width of the drill. To reduce the current draw of each motor, the stainless-steel disc in the metring unit does not run against the friction of a tight seal, with a powerful vacuum to draw seed into the notched edges of metering disc.

As outlined in the picture captions, there are various components within the unit to activate the singulation of the seed and to ensure it is detached from the disc edge from where it is released to drop down into the tube leading to the seed coulter.

Manufactured to tight tolerances, the original metering units are well-proven and rugged but there are several wear elements. Although this wear occurs gradually over an extended working period, close attention needs to be paid to the fit of the disc in the housing, with shims used to take up small amounts of wear. The discs themselves will also gradually wear at the seed cut out notches.

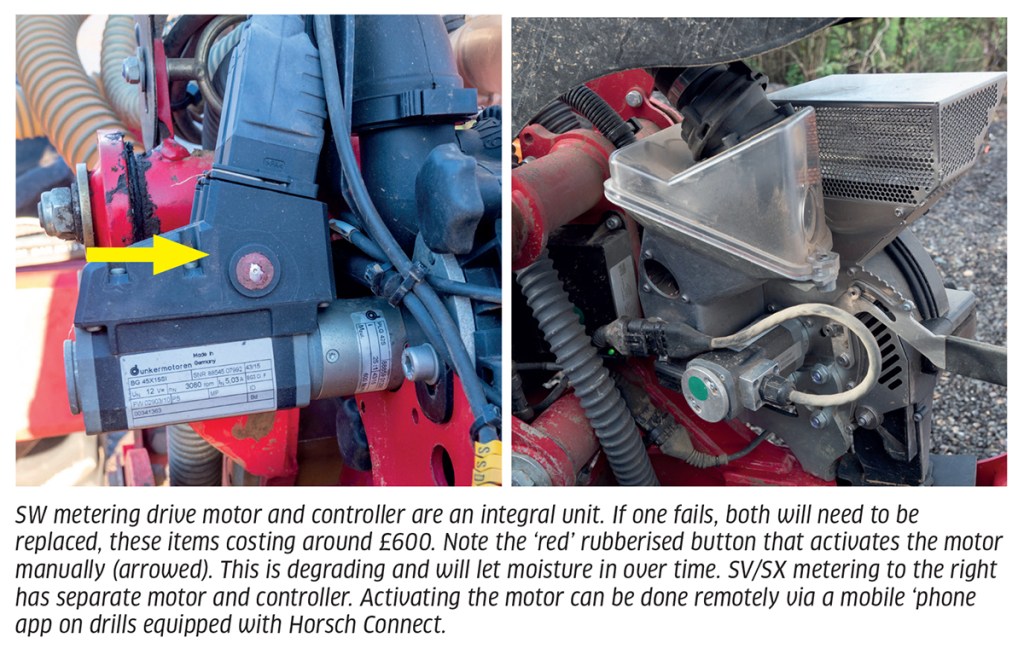

The metering drive motors and drive control module are mounted together. If either of these elements fail they will typically be replaced as a complete unit as these combined elements are ‘programmed’ to work with the drill, with new replacements needing calibrating on installation. As swapping to a replacement is not a difficult field repair, some users will carry a pre-calibrated spare module and motor just in case one fails in service.

The original disc drive motors have an external push button that enables each individual motor to be activated on its own. This allows the metering unit to be both checked for running and calibration. The latter can be achieved either running from seed fed from the hopper or directly via seed fed into the unit via a calibration funnel. The latter system is typically employed when checking individual metering units for accuracy.

For further detail, see picture captions.

SV suck or SX blow

On SV/SX drill models, the metering unit had a complete redesign to make these models easier to maintain. The design does away with metering disc shims with a simplified swap of disc types when switching to different seeds. To reduce the cost of parts, key wear components are made from plastic. Although this material does not offer the same resilience to wear as the previous metal design, the parts that do wear are considerably cheaper and easier to renew.

A further change is that the controller and motor are separate units. If either fails, they can be renewed separately. Calibration of the motors and controlled is also carried out automatically to make replacement ‘plug and play’. Again, see picture captions for more detail.

Another key change is that whilst the metering units of SV models work using the familiar AirVac vacuum system, SX variants employ vent pressurised air AirSpeed that in effect ‘blows’ seed onto the disc.

On SV models, the AirVac system plays no role in the seeds progress once it has been singled out by the metering unit. It essentially falls, via the drop tube, into the furrow created by the seed coulter. Much the same way as with the previous generation SW in other words.

With the SX AirSpeed system, the metered seed is ‘captured’ by the air current flowing through the metering unit, the drop tube becoming more of a shoot tube, with metered seed effectively being blown down and into the soil furrow. To prevent the seed bouncing as it lands, the seed is embedded by a catch roller.

If you were to ask Horsch which system is better you will not get a direct answer but more the suggestion that an SV drill can be worked at speeds of up to 12km/hr, the SX up to 15km/hr. In the UK, most users will typically work at speeds nearer to 8km/hr.

As a used buyer it obviously follows if you are after a Maestro metered drill your choice will be limited to what is available. Faced with the choice of an SV or an SX drill, seek advice. Horsch specialists may suggest an SX is more ‘versatile’ in that it may be operated at a higher working speed.

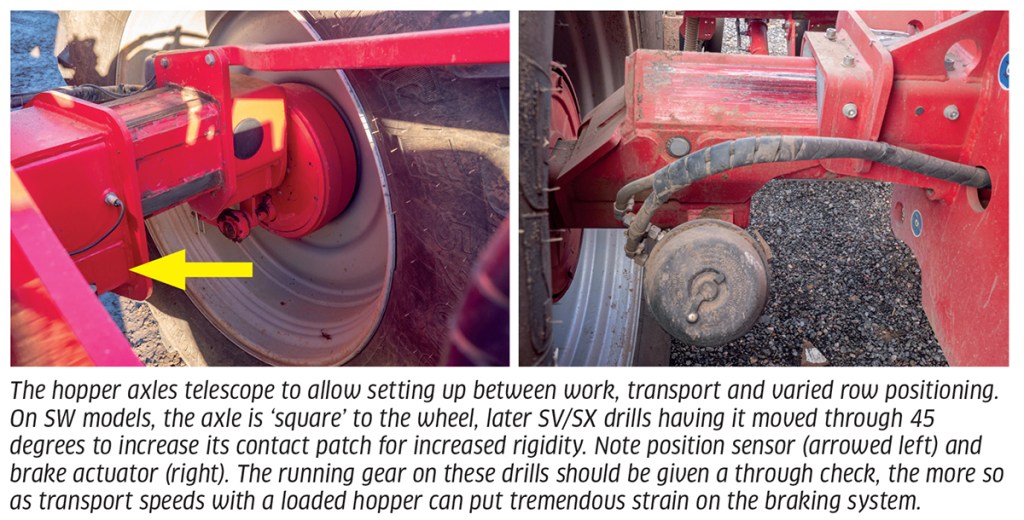

What about the hoppers and running gear?

SW drills have a different hopper design and lids than the current SV/SX range, with the pneumatic blower system and hydraulics that control pressure on the toolbar also differing. From a used buyer’s perspective, these design changes will have no impact upon how the drills operate. The key is to check the pivot points, hose runs, connectors and running gear typically. The build of these trailed drills can be summed up in one word. Robust. Still check for corrosion and accident damage.

When it comes to the electronics and control software, you will be able to check this either via a dedicated Horsch display, which is a less common find these days, or via the ISObus head unit in the tractor. If you cannot hook a tractor up to the drill you will not be able to check the important control systems and run up the metering units to ensure they operate as they should.

With reference to software, a Horsch dealer will ensure the drill will work with a tractor’s ISObus system. There should be no compatibility problems, but it is still worth checking.

What to look for

As these drills are specialist items of kit, with used examples thin on the ground, it follows your starting point will be to talk through your needs with a Horsch dealer who, in turn, will work with Horsch UK. The latter know where all Maestro SW and current SV/SX models are and if any are available used.

An outline of the basic metering unit checks is listed in the picture captions, with less attention focusing upon the hopper and tool bar elements. This is not to suggest the latter an unimportant when it comes to checks but more that it is the ‘Maestro’ drill elements that should be you core focus.

As to choosing between and SW or later SV / SX drills, the former are equally as capable as their successor models. The downside if they are not as easy to look after and when parts within the metering system need to be renewed those parts will also be more expensive.

SW drill models that are available are likely to be in good order and should make a sound buy but you will need to keep on top of maintenance and really look after the drill. Well maintained SW drills should continue to retain a strong residual value, but you do need to accept that as these variants are no longer in production, they will not be worth as much further down the line.

If you have deeper pockets and are looking to keep the drill for an extended period it follows that the later SV/SX models can make a better longer-term investment. No surprises there of course. You get what you pay for. But when it comes to a fight between which one will do the better job, then there is not a lot in it.

Prices

With so few used examples of trailed SW and later SV/SX drills to choose from, pricing is perhaps a bit tricky. If you consider the 16-row examples as listed, these may retail for perhaps £85,000 and £145,000 respectively. Look around, and you may find an SW selling for a bit less. But in the simplest of terms, consider a Maestro SW drill costing upwards of £5,500 a row and holding back around £1,000 per row to pay for new wearing metal. Later drills with the less expensive metering unit internals are not ‘better’ drills but they will be easier and potentially less costly to look after.

Summary

If you are interested in a Maestro SW or later SV/SX model, the used buying advice is simple. Talk to users and Horsch dealers. As to other drills with the Maestro metering units, these are more widely available and will of course offer the same levels of per row performance. Where the ‘S’ models score is in their ability to drill large areas without stopping.

With thanks to: R C Moore & Son, Bishops Itchington, Warks, Robert Tuckwell Contracting, Mursley, Bucks, Matthew Kennedy, Olivers, Tingewick, Bucks and Thomas Mold, Horsch UK .

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.