With four-wheel-steering, central tyre inflation, full suspension, a 66km/ hr travel speed and up to 335hp under the bonnet, JCB’s new mid-range Fastrac 6000s appear to be pretty multi- talented machines. We take a closer look

KEEPING IT BRIEF

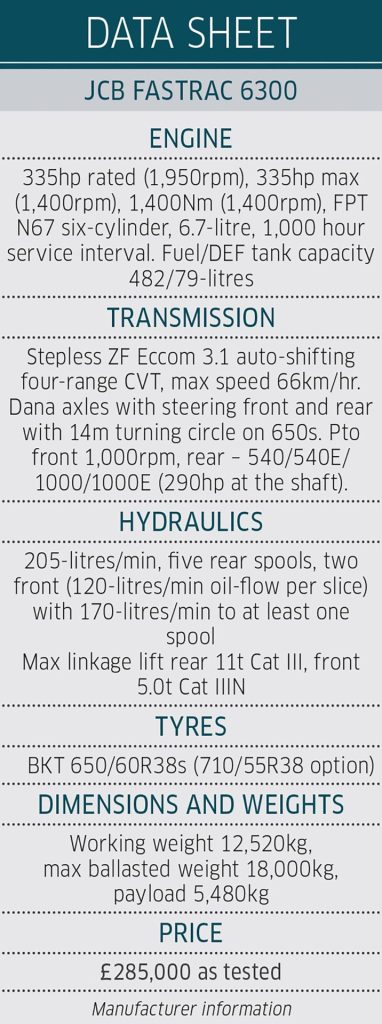

- Two models – 6260 and 6300 – with max power of 284hp and 335hp respectively and working weight of 12.5 tonnes

- FPT engine and ZF CVT in place of Agco Power/Fendt Vario powertrain pairing in 4000- and 8000-series

- Dana steering axles front and rear in place of in-house built beams used on existing models

- Twin antenna GPS working with trademark four-wheel-steering

- Central tyre inflation to improve traction for fieldwork

It’s fair to say there are few surprises in today’s agricultural equipment world. The internet and social media have done away with any opportunity for manufacturers to keep prototypes hidden from public view. Whether it’s spy-shots or opportunistic by-standers enthusiastically grabbing whatever they can, it’s rare that any pre-production machine will stay under wraps until its official launch.

One of the worst kept secrets of recent times has got to be JCB’s freshly launched 6000-series Fastrac. For the last ten years there’s been a glaring gap in the British manufacturer’s line-up and the firm’s model numbering did nothing to disguise it.

At one end of the spectrum you had nimble 167hp-218hp four-wheel-steer 4000 models while at the other the much larger-framed 281hp 8290 and 335hp 8330. Though the former were widely viewed primarily as transport tractors, the big-wheels-at the back, small-ones-at-the-front layout of the 8000-series made them more attractive as draft machines capable of high road speeds. But for over a decade there has been nothing in the middle ground. Whispers have scuttled around the industry – particularly in Agritechnica years – that an intermediate Fastrac model is on the way.

It came as no surprise therefore that earlier this season pictures started floating about of a different looking, angular-edged yellow-skinned beast. That was shortly followed by a missive from JCB Towers for dealers and the press to report to World HQ in Staffordshire for a briefing on these mystery machines. The Fastrac 6000 had landed….

New plan

Although its arrival might not have been unexpected, what many in the know weren’t anticipating was such a drastic from-the-ground-up revamp.

Having been privileged to have the opportunity of an early test-drive of the new 6300 as well as the chance to talk to the engineers involved in developing and analysing the performance of pre-production field-test tractors, we’ve been able to glean a useful insight into just how much work has gone into this latest iteration of the Fastrac.

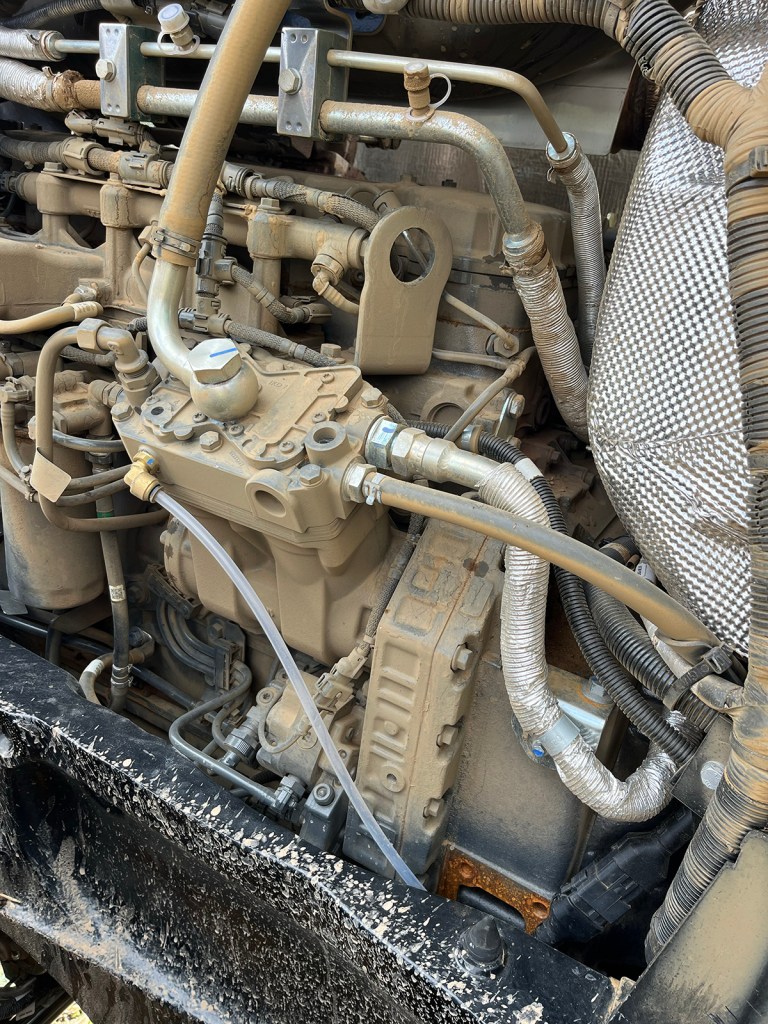

Most strikingly there’s a dramatic shift away from the current Agco Power/Fendt Vario engine/transmission pairing. Instead, the new mid-range models employ a 6.7-litre FPT Industrial motor coupled with a ZF Eccom stepless CVT – a pairing already used in the Claas Axion 900 and McCormick X8.

While the same basic Fastrac principles remain – mid-mounted cab, proper suspension, full ABS braking, 66km/hr travels speeds – it’s actually only the cab frame and control layout that are shared with existing models.

Aside from the driveline and power-plant, the 6260 and 6300 gain Dana steering axles front and rear in place of JCB’s home-built beams used on 4000-series tractors. But the two new models also get certain other features that are entirely fresh to JCB – twin antenna NovAtel GPS steering and an in-house developed central tyre inflation system. More on all of that later…

Powertrain exchange

The swap from an Agco Power engine to an FPT motor will come as a surprise to many. Why the switch away from what is considered to be one of the industry’s most rock-steady reliable power-plants?

While cynics might suggest there’s a mysterious back-story, JCB says that it’s simply down to the physical dimensions of the block. With its timing gears situated on the backend of the motor, the 7.5-litre AgcoPower engine capable of providing the power required would have made the tractor too wide at the waist to enable tight turns with decent front-end rubber. Other engine options were considered – Cummins couldn’t meet the design criteria for a front pto while MAN didn’t have a Stage 5 emissions-compliant motor in its smaller engine line-up. Fiat/Iveco was therefore felt to be the obvious choice.

But the 6000-series’ 6.7-litre motor isn’t just an off-the-shelf purchase. Its physical attributes are very different to a standard unit – the intake manifold and turbo are specific to the Fastrac and the sump is tailored to fit the sculpted chassis at the same time as ensuring optimal oil flows to allow service intervals to be stretched to 1,000 hours.

FPT has worked with JCB to develop a power curve specific to the Fastrac’s needs. That’s resulted in peak power and torque being generated at much lower revs than usual. On the 6300 torque pretty much plateaus between 1,200-1,800rpm and strangely the maximum power of 335hp at 1,800rpm is the same as the range-topper’s rated output. Engine rpm is limited to 1,950rpm and the fuelling map is focused on generating maximum efficiency much lower down the rev range. JCB says it has focused its software engineers’ attentions on the fuel consumption sweet-spots that occur toward the lower end.

Their job has been to develop an umbrella package that spans both the FPT engine and the ZF Eccom gearbox. Tagged Smart Transmission Control (STC), we’re told the main focus of this in-house developed system has been to get both engine and gearbox to run at the points in the rev range where performance is at its best. For the ZF box there are peaks in each of the four ranges where hydrostatic and mechanical drives transfer maximum power with minimal parasitic losses. Tying these with the low-revving FPT power-plant’s optimal power and torque bands, JCB’s team think they’ve nailed the balance between frugality and performance.

The switch in engine and transmission has necessitated a fairly big change in chassis architecture for the middleweight Fastrac. While the rear three quarters remains a fabricated ladder-type arrangement, the front end is now a cast construction better able to cope with the loads generated by its 5,000kg capacity Zuidberg front linkage. The Dutch manufacturer also supplies the new tractor’s front pto which has an operator-friendly trick up its sleeve. It has a reversible stub-shaft that – with the removal of a single circlip – can be quickly flipped round to switch between 21- and six-spline implements. It also has an efficiency saving feature when not in use, only circulating lubricating oil rather than staying at standby pressure.

Running gear

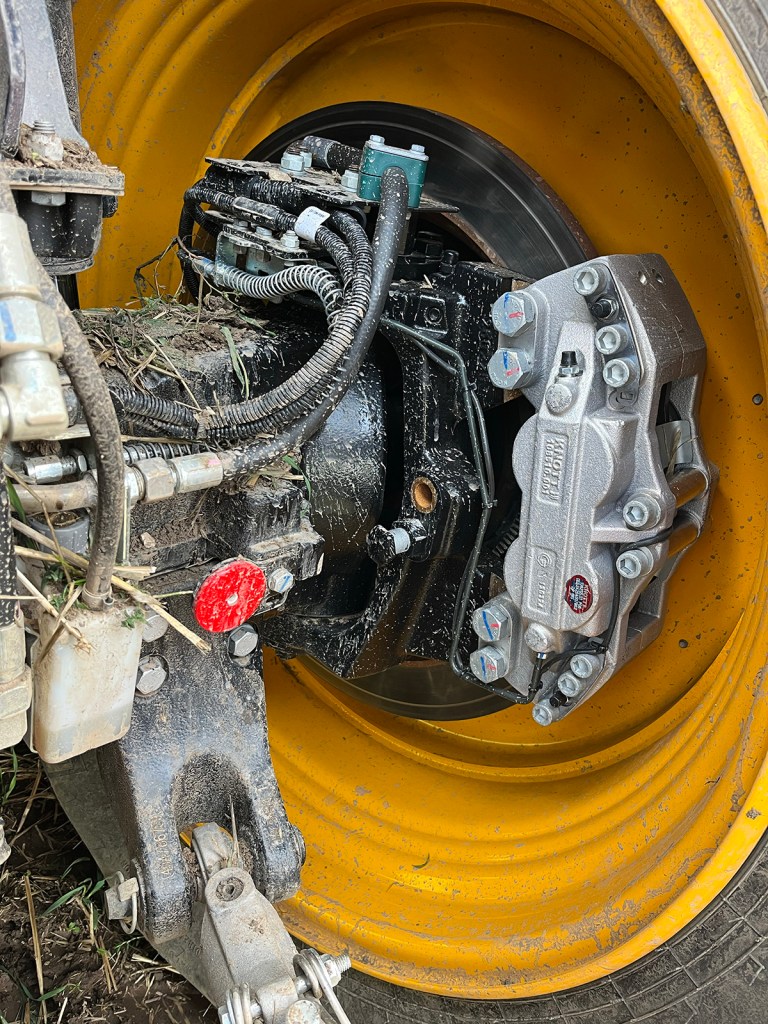

There’s been another major change in the 6000’s undercarriage. Gone are the JCB-built axles. In their place beefy Dana beams are employed. We’re told this switch has nothing to do with the issues early 4000-series Fastracs suffered in this department, it was apparently simpler to outsource axles capable of dealing with the higher torque and power loadings generated by the new powertrain.

A key design brief was dual wheels and a 3.0m track with high implement loads. This resulted in a wide kingpin spacings, too broad for JCB’s machining centre. Dana also has experience in CTIS design – its knowledge in this area aided in the development of the Fastrac’s new party-piece.

This change has also enabled a redesign at the hub end so that the external brakes are now much simpler to service. Where previously a disc change would have necessitated a hub removal, the new arrangement is more like an automotive-type design with the discs on the outboard side of the hubs. As a result, we’re told it’s possible to do a complete four-corners pad and disc change in under four hours.

The new setup uses a single four-pot calliper as opposed to the twin-piston pairs on the 4000. There was a distinct lack of brake squeal in our hour-long road test. As previously the anchors are ABS-equipped with a trailer feed at the back of the tractor.

Unsurprisingly anyone considering the step up to a 6000 needs to expect a compromise in agility. The new tractors still have steering front and rear with the backend responding to turns of the wheel at a ratio of 2:1 with the front. However, the longer chassis and bigger tyre options mean the larger-framed sibling’s turning circle is some 15% wider as a result. On 650mm wide tyres it’ll pull itself round in approximately 14m.

While these new models employ the same basic self-levelling hydro-pneumatic suspension set-up as existing Fastracs, the system has been further refined so that pressures are monitored on each side of the rams. Measuring bounce and rebound multiple times every second, the suspension is said to be able to respond faster to changes in axle loading and is therefore better at ensuring traction to each of the four corners in the field.

Tyre pressure

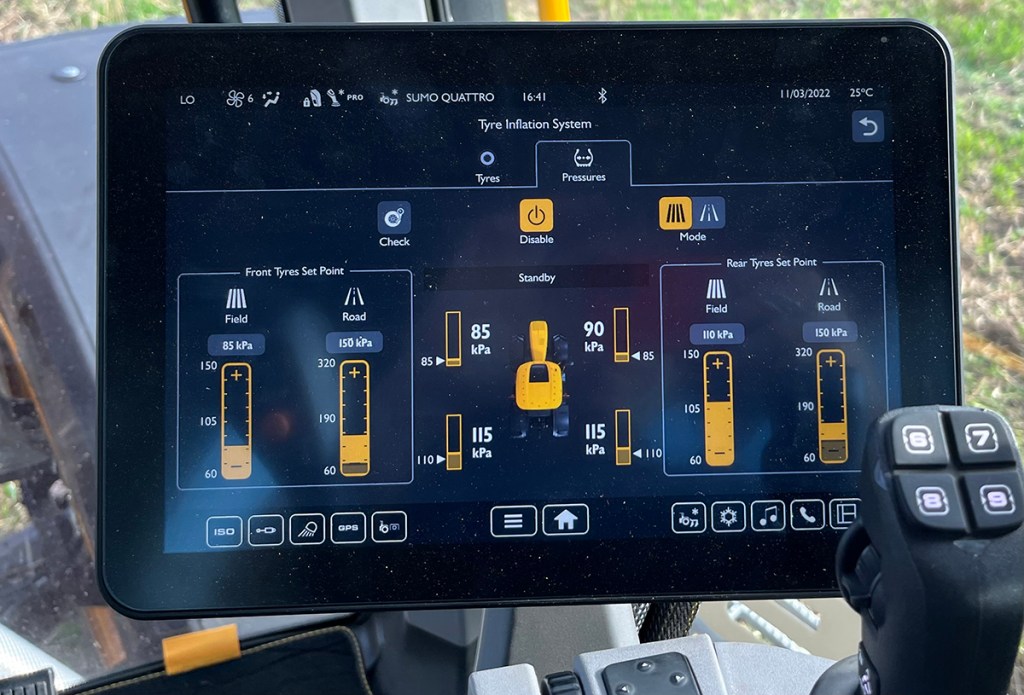

The 6300 is the first to gain a central tyre inflation system. A £15,067 option, the in-house developed arrangement differs from other set-ups in using a single-line design. Rather than supply and return pipework to each wheel rim, the JCB system has one hose routed through the back of the king-pin and out through the hub via a rotary seal to supply air to the tyre in question.

Not requiring any complex electronics, clever pneumatic valves in the wheel rims open and shut under different ‘signal’ pressures to inflate and deflate individual tyres. To boost tyre pressures air is delivered at a high volume, low pressure. Once in the field the operator gives the system the nod on the ICon touchscreen – the valves receive a high pressure, low volume blast which sets them to their vent position. With the target level reached the supply is switched off and the valves seal up.

With the job in the field finished the driver hits the appropriate screen prompt and all four tyres re-inflate to road-going pressures. Typically, it’ll take the twin on-board compressors just over four minutes to jack all four corners up from 1bar to 2bar and about 47 seconds to drop them by the same amount – an operation that can be done while on the move so long as you’re travelling no faster than 40km/hr.

One novel feature is the ability to vary each wheel pressure independently. While the opportunities for using this unusual feature might be limited, JCB says there are big advantages when running offset linkage-mounted equipment such as long-reach hedge-trimmers.

While that might aid in stability, the real advantage of having a CTIS set-up is that it answers one of the age-old Fastrac criticisms – traction. An industry shift to VF tyres capable of running at ridiculously low pressures means footprints are widened and lengthened, compaction is limited and getting power to the ground is now that much easier. Where previously front end and rear deck weights were crucial for any yellow-liveried prime-mover required to do big chunks of draft intensive fieldwork, CTIS has – in part – done away with the need for extra ballast as a means of gluing the tractor to the ground.

Guidance from above

While the new Fastracs may have clever technology deep down in their boots, they’re also set to benefit from heavenly enlightenment. A new GPS set-up sees a pair of NovAtel receivers secreted into the cab roofline – one on the left the other on the right.

We’re told there are two key advantages to this arrangement. Firstly, even when sitting stationary the tractor knows which way it’s facing so when it takes off there’s no dithering, trying to work out which direction is should be heading. This in turn means line acquisition on the headlands is that much quicker and slicker.

The other advantage of the twin antenna approach is that the system is now much more sensitive to heading, particularly on side-slopes. This means that it can better compensate for crabbing, independently steering front and rear axles to keep the implement behind on track.

So how does it drive?

Clambering up the steep cab steps, assisted by the canary-yellow grab bars, the world you enter is not unfamiliar. To all intents and purposes 6000-series Fastracs have the same cabin and control layout as their smaller and larger siblings. However, the roof-lining has had an overhaul primarily to accommodate the twin GPS receivers but also to host an uprated sound system – an optional sub-woofer can be positioned under the left-hand seat to impress any deep bass loving guests.

Although it’s still relatively new, the ICon touchscreen controller has had a raft of behind-the-scenes updates. Capable of handling all the detailed tractor settings, as well an ISObus implements and GPS steering, there’s now the option for a second screen that can be positioned in various locations around the cab.

The armrest controls are much the same as before – LED colour-coded spool paddles that can be swapped about working alongside assignable numbered function buttons on the main joystick and the secondary loader/linkage stalk that sprouts from the right of the console.

Once seated a squeeze of the trigger and a nudge of the joystick bring the transmission to life as does the old-school shuttle lever. The tractor can then be driven on either the throttle pedal, the drive lever or using the cruise control thumb roller. The park-brake on these new models now automatically applies/releases and there are now menus to pre-load engine revs for forward-reverse shuttling as well as adjusting how aggressively cruise speeds will engage.

Annoyingly there is no press-and-hold function for the engine speed presets – revs all need to be set and tweaked through the appropriate menu screen. JCB says it will put this right on production tractors.

Heading out onto the highway via a rutted track with an 11.5tonne Bunning spreader in tow, the 6300 proves the point that its hydro-pneumatic axle damping is difficult to beat. While it irons out the lumps and bumps off-road, once on the blacktop it works away to resist all the lateral and nose-to-tail forces generated when you run a 24-tonne rig up to over 60km/hr.

It’s all very well having the muscle to propel big lumps of steel along at such speeds but slowing down is equally important. While the Fastrac’s external anchors are more than capable, the move to an FPT engine has allowed JCB to integrate an automated exhaust brake into the set-up. Initially activated by an on-screen prompt, a flap in the base of the stack then flicks open and shut as you back off the throttle pedal. At the same time the variable pitch fan blades are cranked hard over, these two functions having a big impact in retarding the engine, slowing the transmission and providing an impressive parachute effect.

The downside is the noise this jake-brake arrangement generates. Up in the cab a roar enter’s through the rooflight every time you ease off the throttle. JCB says this will be rectified on production models with better sound deadening around the Perspex and the option to select exhaust braking and fan retardation independently of each other.

Our brief encounter with the new Fastrac highlighted another difference over what’s gone before. That trademark Vario whine as the tractor works its way up and down through the hydrostatic segments of the twin range box is gone, replaced by a gravelly growl from deep within the bowels of the ZF CVT.

The other point of note is JCB’s addition of a car-type auto engine shut-off for when the tractor has been left idling for a while. Irritating as it is, we’re told it’s all about avoiding particulate filter soot build-up and the need for incessant regen cycles.

WHAT CHANGED? – THE DESIGN EVOLUTION

For the last three years various different iterations of prototype and pre-production Fastrac 6000s have been out for field and road testing – in the UK, in the freezing conditions of the artic circle and sweltering southern Spanish summer heat.

- Rear link arms – “To accommodate the rear axle steering we needed a crank in the link arms. But with a heavy, high centre-of-gravity implement such as a power-harrow drill we saw the forces exerted were creating a twisting effect at that weak point, despite them being made from 1000MPa steel. The solution was simple a deeper-profile arm, stepped to accommodate the hook-ends.”

- Air-conditioning – “We’ve moved to a variable displacement compressor, fans and heater matrix for the HVAC system which is more efficient and should have a better cycle life – it’s like load-sensing for the air-con. But when pre-production machines were out working in last summer’s intense heat there was a failure in the LINBUS system that controls it. Annoying as it was for the guys driving the tractors at the time, it was actually quite a simple software fix.”

- Rear pto – “The initial ZF pto arrangement employed interchangeable 21- and six-spline stub shafts secured with three studs. But with such heavy loading going through that driveline we wanted to minimise the reliance on hand-torqued bolts so we asked ZF to go to a four stud arrangement, effectively reducing the risk factor by a third. At the same time we added a 1/2in square recess in the end of the shafts to make it easier for operators to stop them rotating when doing up the bolts.”

- Central tyre inflation – “Although we didn’t have any major failures with our own CTIS design we learnt from our component suppliers what works and what doesn’t. Most systems work on the basis of high pressure inflation and low pressure deflation which seems logical. But what we learnt was that this method reduces axle seal life, particularly when on the move. That’s why we went to the opposite approach and put a limit on the travel speeds for tyre deflation as well as integrating air cooling into the main radiator package – it’s all been designed to maximise service life.”

Nick Fone

For more up-to-date farming news click here and subscribe now to profi and save.