Krampe debuted its first push-off trailers over three years ago, and now the second version of the RamBody is out and about. We tested the German trailer maker’s middle model, the 750+, on carting maize last season.

KEEPING IT BRIEF

- As usual with Krampe, individual modifications and customisation are possible

- Numerous LED lights can be switched on using the ISObus connection to brightly illuminate the

immediate surroundings. - Alongside the 750+ there are the smaller 680 and bigger 900 push-off trailers.

Krampe is not a big player in the UK agri trailer sector, but it’s a very different story in its home market of Germany. There it enjoys a good market share in the tipper business, and it’s now looking to snaffle some of the push-off trailer market from its competitors.

In 2022, Krampe launched RamBody, which we had a look at in our November issue that year. Since then, the firm has gained some useful experience and new ideas, enough to introduce its second generation of RamBody trailers in capacities of 22.3m³, 38.6m³ and 45.3m³ before you add any volume boosting extras. Our test machine was the middle model 750+.

Manoeuvrable

The 18cm wide drawbar is relatively slim, helping its manoeuvrability, and even more so if you add the optional electro-hydraulic forced steering systems for the BPW axles (around £7,740 extra).

This is where the ISObus-capable RamBody boasts an edge. The forced steering system doesn’t use sensors; instead the target angle is calculated electronically, and the system then adjusts the angle depending on how fast the tractor and trailer are travelling. During our test it worked really well.

The trailer drawbar is cushioned by two silent blocks. You can play around with the drawbar height to match your tractor, and a K80 spoon is the standard coupling from the manufacturer.

When hitching up, all that needs plugging in are the load-sensing hydraulic connectors, the road lights and the ISObus plug. Krampe also fits a hydraulic parking stand as part of the standard package, and this is operated from a double-acting spool.

Intelligent technology

The main trailer frame is fabricated from rectangular tube, which is fully enclosed. This is said to save weight, provide stability and make cleaning much easier. While such an approach works well on their tippers, cleaning the push-off trailer is still a little more time consuming as you raise the body to help wash around the chassis.

As mentioned, the axles are sourced from BPW. The standard set-up uses parabolic springs, though our test trailer was supplied with the optional air suspension, a £1,806 extra. And during the test, the RamBody demonstrated good road holding, with the steering axle tracking smoothly at all speeds; even crossing a furrow at a field edge or driving over a lump at the clamp, it seems stable. However, the body roll does take some getting used to, especially on uneven roads and at typical carting speeds. We reckon that this is partly caused by the RamBody’s high centre of gravity. Plus our trailer was on big 710/50 R30.5 tyres, which wouldn’t have helped the situation, even if they do enable the trailer to travel really well in the field.

To meet EU type approval, Krampe fits a rear bumper/underride guard as standard. This bumper folds hydraulically as part of a fully controlled sequence when opening the tailgate. Any material left on the bar falls on the ground when it is lowered back into position. You also have the option to raise/lower the underride guard independently of the trailer tailgate using the ISObus terminal controls.

Smart solutions

Krampe had also fitted our trailer with the optional Wabco Smartboard (£1,075). This also uses ISObus and allows you to record the kilometres travelled or the pressure in the air bellows, for example.

Even more beneficial is the trailer weighing function, which can also be calibrated. The system is very accurate, and deviations are in the single-digit percentage range. We found it useful for checking gross weight and payload, especially in varying maize crops. Smartboard can also be used for monitoring tyre pressures with the OptiTire system.

Body and crop covers

The body has undergone a few changes compared to the first version. It’s still straight and features the slanted stanchions from the original RamBody. These are angled in the opposite direction to the pusher blade to maximise stability. The sides are two metres high, with £2,795 aluminium extensions adding another 30cm to the overall height. Our test trailer measured 4.05m with the big tyres and greedy boards.

We really liked the steep mudguards that stop material collecting on top of them. The body structure is bolted to the chassis.

The volume tailgate is also new. It increases the load space by 2.3m³ compared with the original, flat tailgate. It costs £1,230 and is the reason for the “+” in the model name. There are some rumblings that Krampe will probably discontinue the flat tailgate, but this hasn’t been confirmed.

When opening, the tailgate lifts out of the hooks and then swings open; when closing, it settles in these hooks and seals the body. A grain chute with plastic runners is also included in the back door.

We liked the trailer’s load covers (£2,800), which consist of two nets that are operated hydraulically by a small ram on either side. The opening/closing is controlled on the screen and took less than 30 seconds when we timed it.

A new plate

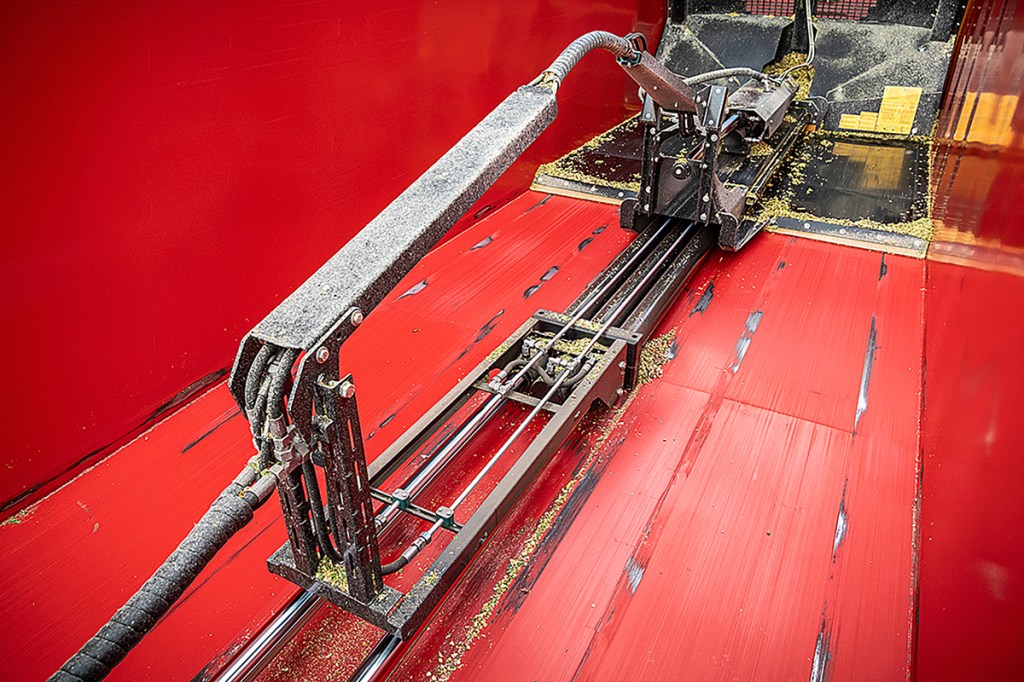

Krampe has redesigned the pushing plate. Now funnel-shaped, it offers more stability than the previous flat version.

We really liked the very good visibility into the body: the holes in the headboard are big enough to see what’s going on in the trailer, yet small enough to prevent much maize from trickling through the holes. For smaller material, Krampe supplies Plexiglas panes that are fastened onto the push plate. The plate is sealed all around with adjustable rubber strips, and there is an adjustable flap at the top of headboard, which is controlled from the terminal using the load-sensing system.

Two hydraulic rams give the initial push on the headboard, with each subsequent shunt done by a single stage on the main ram. Krampe hasn’t changed this from the first RamBody, as it is a reliable, stable system, and other more experienced push-off trailer makers employ the same set-up.

The technical payload of the 750+ is said to be 22t, but that partly depends on the type of material you’re hauling. We checked the unloading time — 48 seconds to push off a 20t load of silage, which is OK. Krampe has changed all the hose routing, because the scissor-like zigzag layout on the first trailers didn’t work properly. The hoses are now laid out in a straight line above the cylinders.

There is a separate compacting function on the control box to help operators use it correctly. We used this feature to cram a bit more maize into each load, but we did have to keep an eye on our weight in some of the damper crops.

ISObus creates opportunities

The interaction between ISObus, the load-sensing system and the Wabco Smartboard makes it nice to use and you have handy information such as the current payload always available. We really liked the added features too, especially the auto functions such as unloading (open the tailgate, push off the material, close the tailgate).

During the test, we had sporadic operating issues. However, these were resolved when the software was updated. Krampe says it would like to offer ISObus operation as an option. The base spec RamBody would then be operated directly from the tractor spools, which would help with the cost. Nonetheless, we think ISObus makes sense on the push-off trailer as it brings extra functionality and user friendliness.

Summary

We operated the latest generation Krampe RamBody 750+ for three weeks on carting maize last harvest.

The trailer rides well behind the tractor, but the operator does have to get used to the body roll at higher speeds.

We liked the numerous options offered by the ISObus-compatible trailer as well as the Smartboard. The controls are logically laid out and easy to get to grips with. We also didn’t have any issues with the build quality. List price for the tested trailer model is an eye-popping £76,723.

Christian Brüse

For more up-to-date farming news click here and subscribe now to profi and save.