When KRM asked Sola for a grass sowing drill, the Spanish company was able to utilise several parts from its existing machines to come up with the GS300. We caught up with one of the UK demo units in the Yorkshire Dales.

KEEPING IT BRIEF

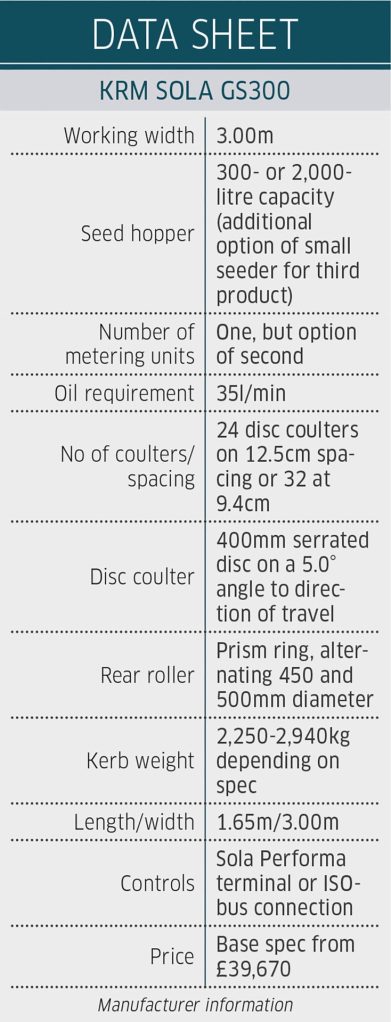

- The GS30 only comes in one working width — 3.00m, but with 24 or 32 coulters.

- Sola drill users will be familiar with the metering system.

- Weight transfer system applies pressure from the underside of the lift arms

- Prices are from £39,670 for the base machine.

The UK grass drill market has been bubbling away over the past few years as farmers look to boost their pasture performance and meet the needs of establishing herbal leys and SFI mixes. Wanting in on the action, KRM has had a word in the ear of drill maker Sola, for whom it’s the UK importer. The Spaniards have listened, coming up with the GS300. While it is a new machine, it does make use of a lot of the Spanish drill maker’s tried and tested seed sowing components.

We caught up with one of the demo units a few weeks back in the Yorkshire Dales. This particular machine has 24 coulters and the smaller hopper capacity of 300 litres. While there may just be one working width of 3.00m, there are plenty of options on the GS300 including extra coulters and bigger, multi-metering hoppers that we’ll get to in due course.

Fresh metal

The headstock and main frame of the drill are fresh off the drawing board. The drill is relatively short, measuring just 1.65m front to back, but it is weighty, which, in part, is due to the prisma roller at the rear; our test machine tipped the scales at 2,250kg with an empty hopper. This mass will be the deciding factor on tractor size, but the Fendt Favorit 716 was getting on fine up and down the Dale.

The linkage is on Cat III spacing and the top link pin can be placed in a fixed or floating slot. There is a potentiometer for turning the metering unit on/off at the headland as the machine is lowered/raised.

Speaking of all-up weight, rather than adding hefty ballast to aid coulter penetration in dry soil conditions, even more so with the 32-coulter version, Sola has employed the weight transfer system that it’s been using on its maize drills for years. When this hydraulic option is activated, a bar presses against the underside of the lift arm. This can provide up to 650kg of extra downforce. A pressure gauge on the headstock shows the user how much force is being applied while a neighbouring accumulator provides some give in the system as the machine is lifted at the headland rather than having to manually reset the system on each bout. Smart thinking.

A bit more travel in the hydraulic ram would be advantageous when it comes to hitching up. Because the disc coulters presumably push up the frame height compared to the maize drill, the hook ends on the lift arms can barely get low enough to latch onto the balls while clearing the lowered weight transfer bar. Annoying.

Parking stands that slide into the frame keep the disc coulters off the ground when the machine is parked up. The stands are stored at the front of the frame, and they do have a second purpose when it comes to setting the seeding depth. The stands slot into the roller frame when the machine is raised, allowing you to then put in or take out the depth limiting shims. Again, a good solution; in fact there are lots of nice details around the machine.

Big drill features

You have the choice of pressurised hopper, a 300-litre as fitted to the featured machine, or a larger 2,000-litre tank. With the latter you can also split it 50:50, 60:40 or 70:30 (£3,040) with a secondary metering unit for measuring out the second material, be it seed, fertiliser or slug pellets.

And if that’s not enough, you can even add a mini seeder (£9,680) with its own 300-litre hopper for handling a third product. A low seed level sensor is part of the standard fitment.

For the metering unit, Sola has stuck to what works on its other drills — an electric driven unit with interchangeable cell wheels for different seed that is capable of 2-400kg/ha. There is a shut-off from the bottom of the hopper if you do need to make a change with a loaded hopper.

The metering unit gets its input from the simple Performer control box or via ISObus depending on which you opt for at the time of purchase — there is no difference in cost unless you need an ISObus terminal. On this particular machine, the ground speed signal comes from a GPS patch antenna. If you go with a split hopper and/or additional seeder, then you will need to go with the ISObus controls.

When it comes to calibration, this will be familiar to existing KRM drill users. A seed catching calibration tray lives at the rear of the machine, and the delivery tube simply slides across so it sends material into the box rather than on to the distribution head. For any smaller seeds, the metal tray can be swapped for a bag with smaller holes so the air flow can vent without forcing out any seed. Once the metering unit has run through its calibration sequence, just input the result into the control box and you are good to go.

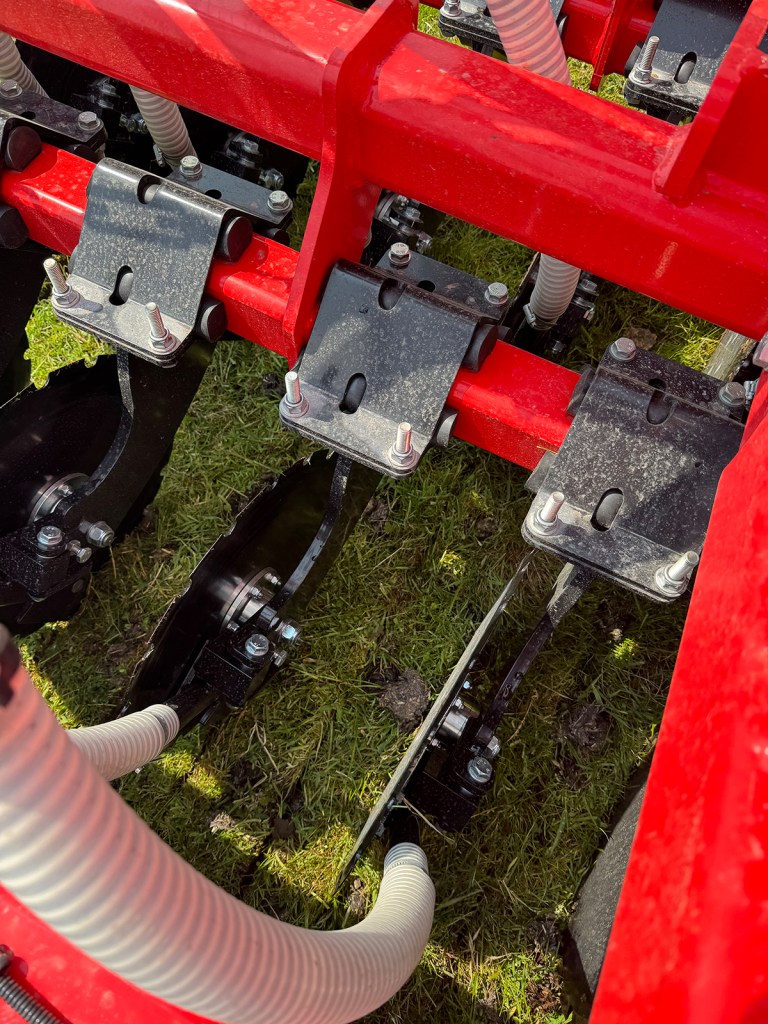

Seed hose routing from the distributor is equally well thought out, with tensioned cable used to support the plastic pipes. The pipes are also fastened to each other at various points, and there are additional sleeves towards the end where the pipes connect to the coulter.

Into the ground

This takes us to the business end of the drill. Like many others, Sola clamps the coulter arm to the main frame, with rubber cord sausages providing some flex in the system. The 400mm serrated disc opener, run at a 5.0° angle, cleaving the ground just enough for the seed to be popped in. Maintenance- free bearings are used on the discs.

There is 60cm between the front and rear disc rows. As mentioned, this particular GS300 is a 24-coulter machine, with seed being dropped in the ground every 12.5cm across the machine’s 3.0m working width. There is also the 32-coulter version, which translates to a 9.4cm spacing between each coulter row.

In work, the drill was producing neat cuts in the old pasture, with the seed placed at a consistent depth wherever we had a look. Even the undulations in the field did not seem to make a big difference to the coulters’ contour following ability.

Summary

The GS300 may be the first grass seeder from Sola, but it’s a well thought out machine that features components that have proven themselves on the firm’s other drills. It also seems to tick all the boxes when it comes to hopper size, number of metering units and coulter count choice. Plus, this drill makes use of the prisma ring roller, which always impresses me when you see the job it does. It’s also a relatively short drill, which should mean that the coulters are able to run at a consistent depth as the machine follows over ground undulations. There were certainly no issues on the day we tried out the drill.

Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.