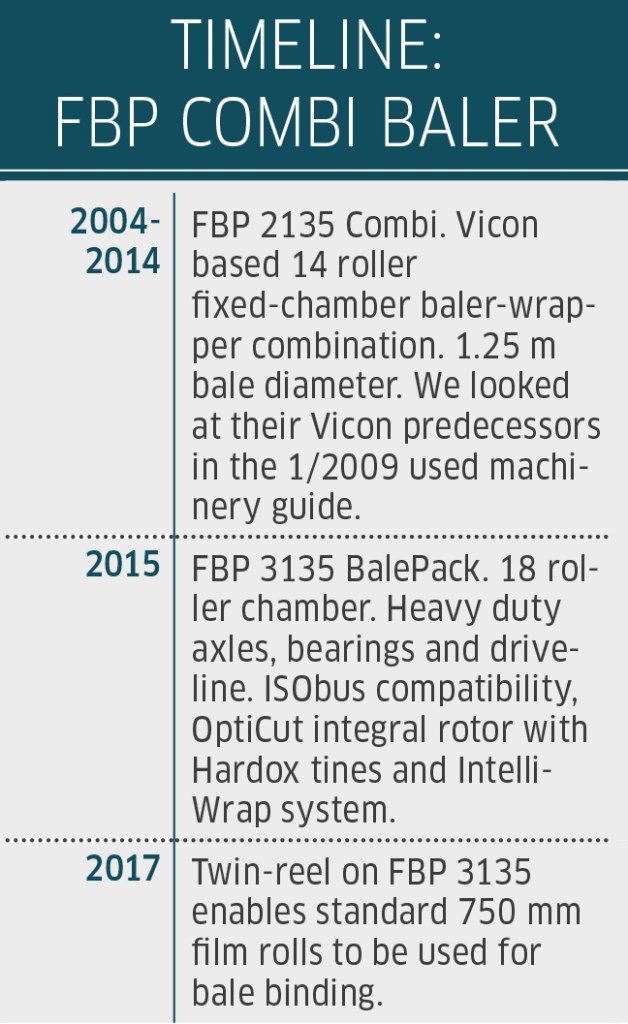

Kuhn launched its fixed chamber FBP 3135 BalePack wrapper baler in 2015, with an update to the Twin-reel binder in 2017. The variable chamber VBP 3165 Combi Baler was introduced in 2019, a Twin-reel film wrap system, like that used on fixed chamber balers, arriving in 2021.

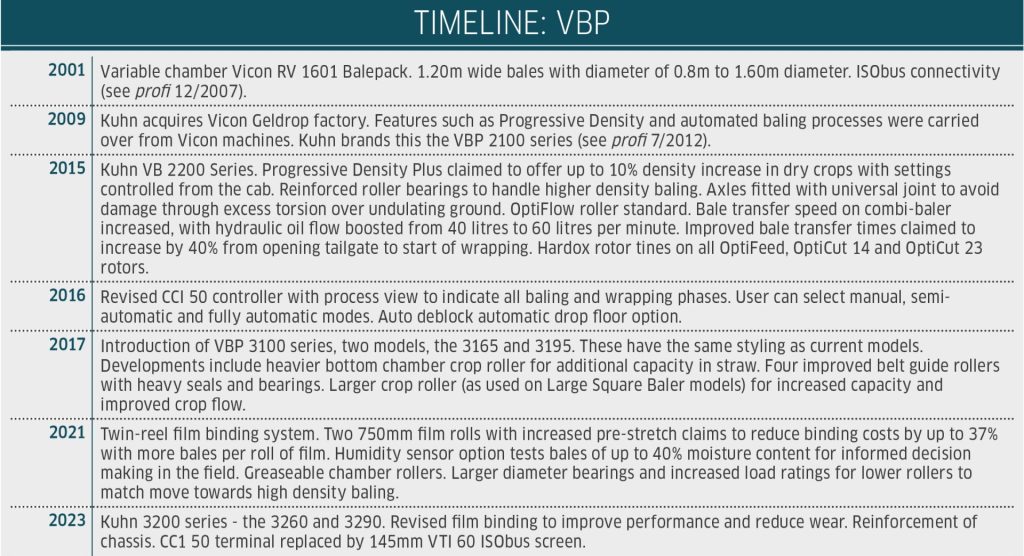

First, a little bit of background to clear up any possible lingering confusion between Kuhn and Vicon balers. Back in early 2009, Kuhn purchased the Kverneland Group baler division, taking over the former Vicon factory in the Netherlands and renaming it Kuhn-Geldrop BV.

Since then, Kuhn branded fixed and variable chamber round balers continue to be produced in this factory. Initially these were based on the same Vicon design with not much more than a name and paint change. Indeed, Kuhn even continued to produce balers for Kverneland under a transitional arrangement which came to an end in September 2010. Today there is no link between the Kuhn machines and Kverneland (including Vicon and Kubota) offering.

The fixed chamber Kuhn FBP 3135 BalePack combi was launched as part of the all-new designed 3100 baler series in 2015. Used Kuhn fixed chamber balers are more likely to be found in livestock areas, as you would expect.

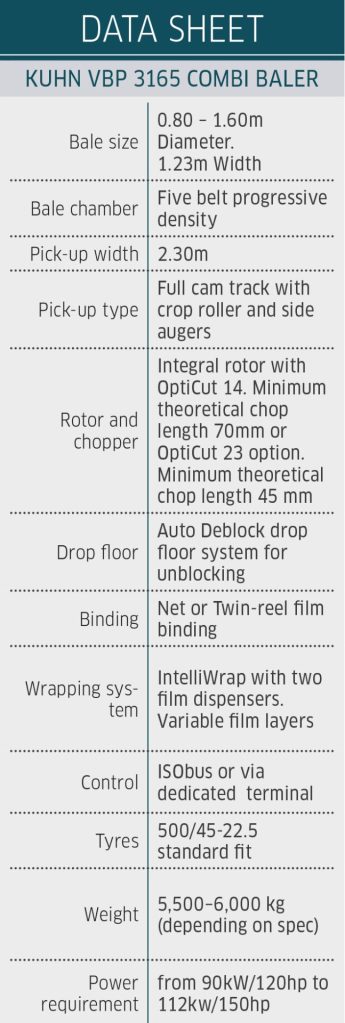

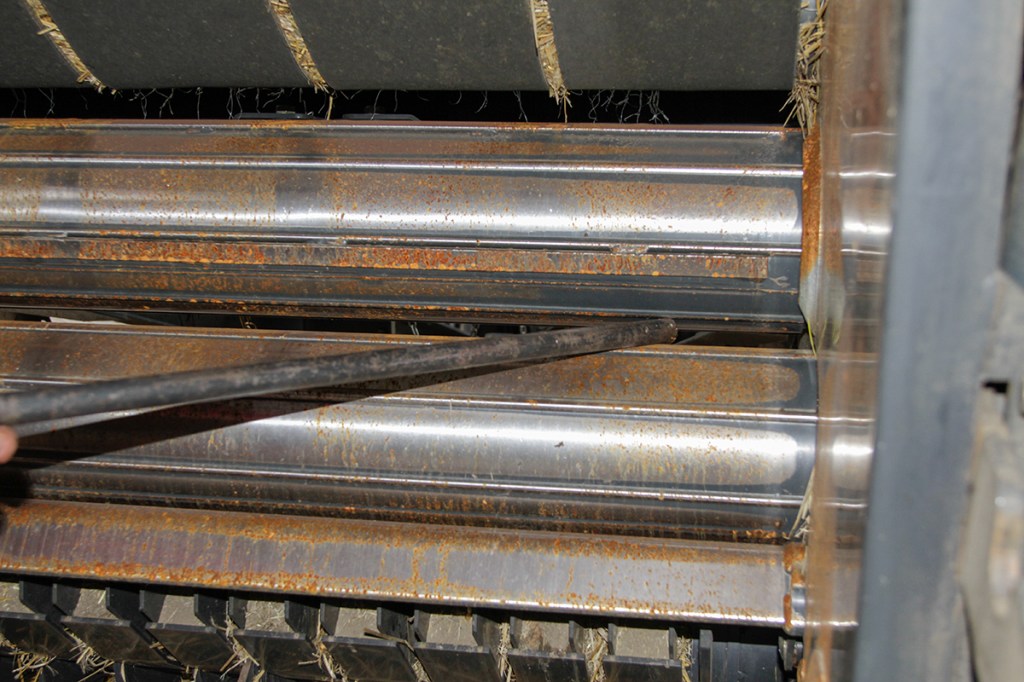

Variable chamber Kuhn VBP 3165 combination balers arrived in 2019. The VBP 3165 has a ‘progressive density’ baling chamber. This uses two chamber rollers, a starter roller and five endless baling belts to produce the bales. As the bale grows, the belt pressure can be adjusted from the tractor cab to compensate for variations in crop quality to maintain a constant density as the bale is formed. The system is designed to cope with dry dry crops such as hay and straw from around 5-20% moisture, haylage at 18-35% and silage at 35-80% moisture.

Kuhn has since replaced the VPB 3100 series with a revised VFB 3200 range. Meanwhile the fixed chamber FBP 3100 models continue as before.

A baler using just net for ‘binding’ is fine if you are baling a lot of straw. However, film-on-film is seen as the way to go if you bale a lot of forage. Not only does it make plastic recycling easier the extra ‘hold’ from the film is said to reduce air hampering the silage process – more on that on page 79 of this issue.

The initial aim of this article was to cover just the fixed chamber FBP 3135 BalePack models. In the UK the variable-chamber VBP 3165 Combi Baler has a strong following, but it is the FBP models are stronger sellers overall, with a split of around 20 and 80% respectively.

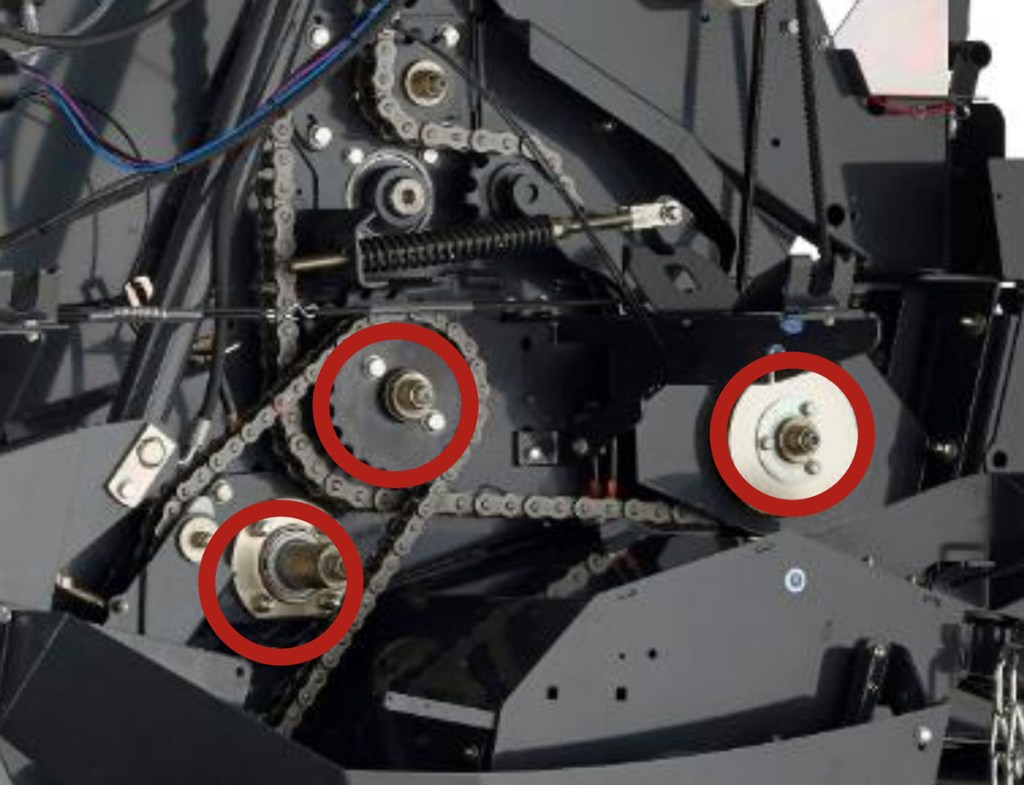

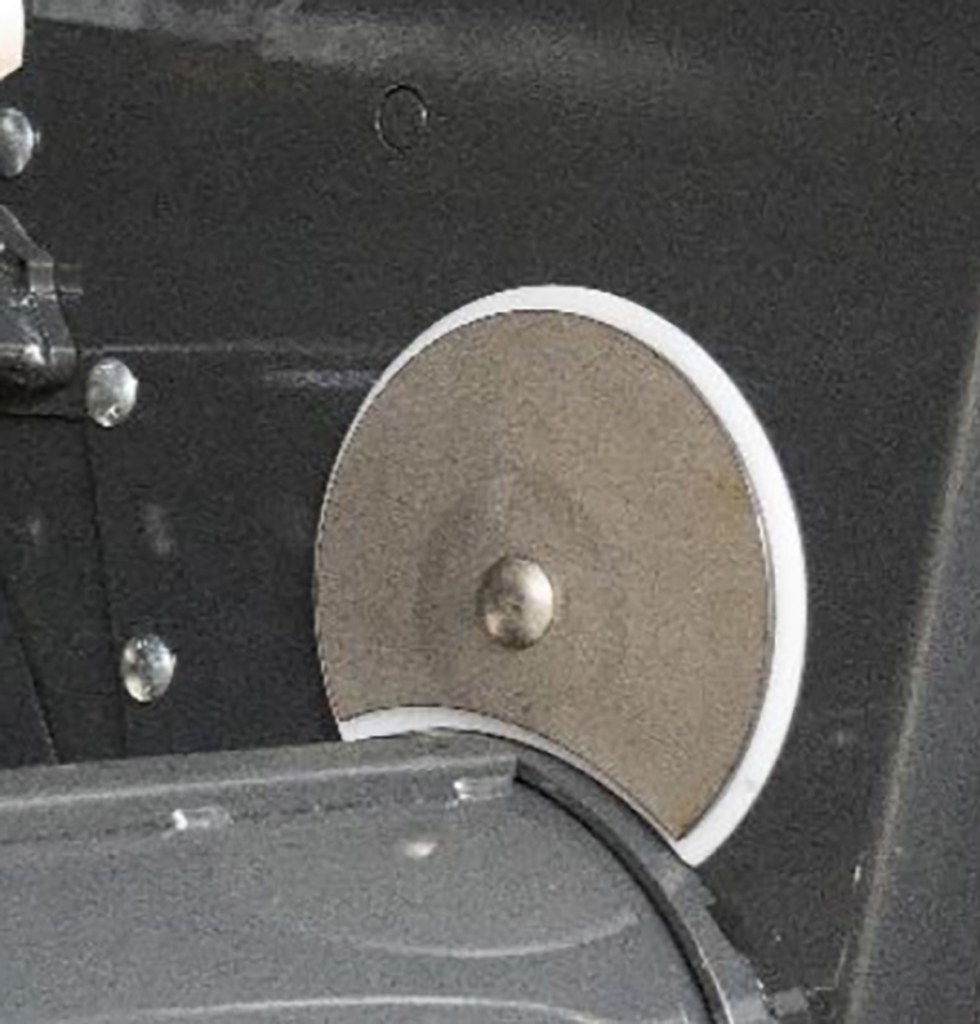

Kuhn VBP variable and FBP fixed chamber round balers in all variants have benefitted from developments with the bale ‘binding’ and wrapping elements having seen the greatest development (see page 52). Other changes are shown in the picture captions.

Summary

No apologies for trying to cover a fixed and variable chamber baler in one article. There are those who suggest fixed chamber combi-balers are the only way to go for forage, with others suggesting a variable chamber baler is more versatile and can always make a smaller bale if dealing with heavier damp grass. There will be those who are on the fence with regard to which system best suits their needs.

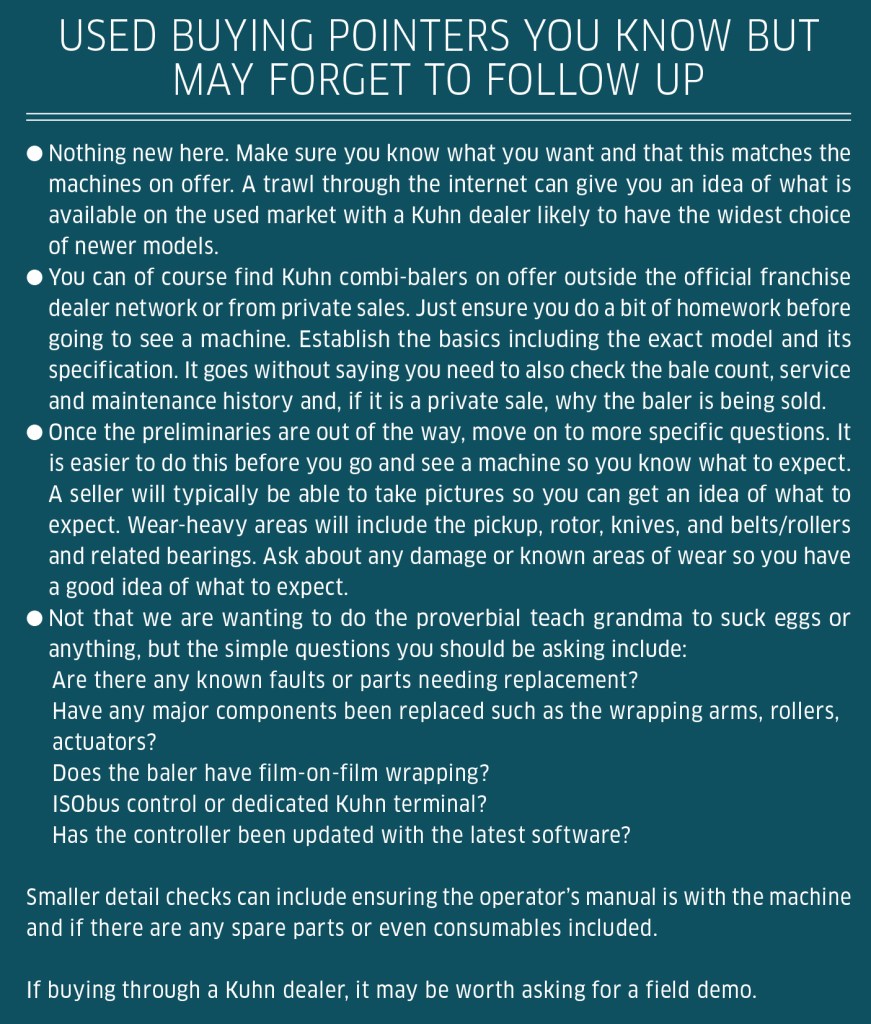

With reference to used buys, now is a good time to look out for a baler that may come up for sale for next year. With the silage making season about to kick-off, this is not the best time to find used examples, the more so if you want to buy locally.

With reference to prices, used FBP 3135 BalePack and VBP 3165 Combi Balers tend to hover around £45k for sound entry level machines, with double that securing a closer to new machine. As always, talking to a Kuhn dealer will help you get a feel for what is out there and what you can expect to pay.

With grateful thanks to: Colin Blood, B and B Tractors, Nottinghamshire, Josh Hardwick, Hardwick Agricultural Engineers, North Yorkshire, Rhodri Jenkins, Kuhn UK and Edd Mowbray.

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.