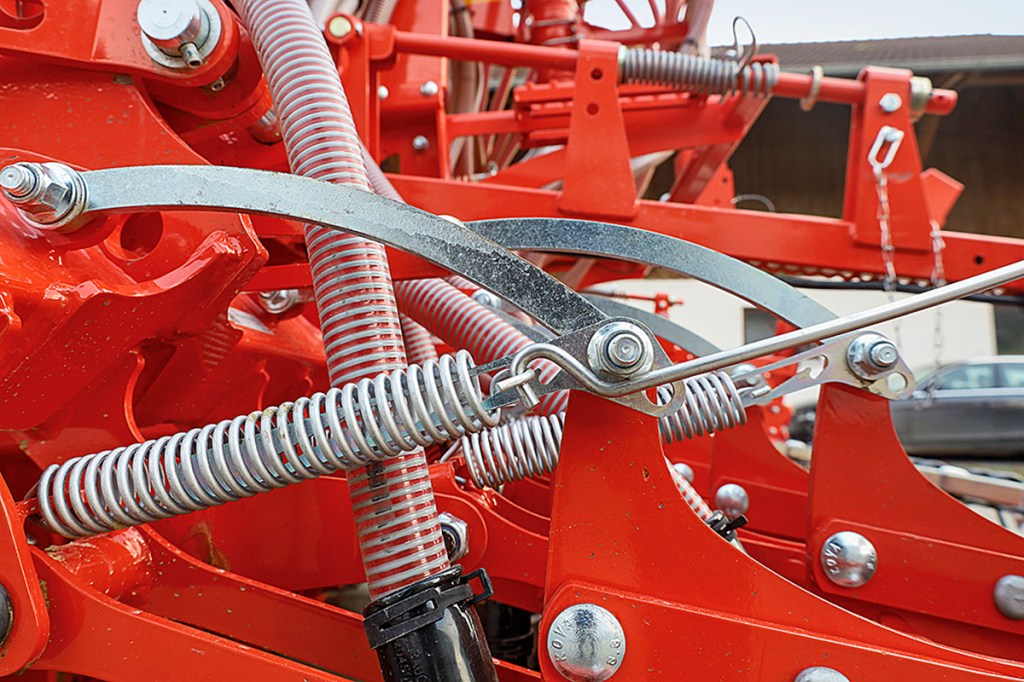

Compact and lighter in weight, the HRB 303 power harrow, and more specifically the Venta 330 drill, combination is also cheaper. So, where’s the catch? We used this 3.0m one-pass last season to find out.

KEEPING IT BRIEF

- The Venta 330 is more compact, lighter and also more favourably priced than the Venta 1010, 1020 or 1030 series.

- Narrower coulter spacing didn’t impact the quality of work.

- From a technical point of view, the Venta 330 has nothing to hide.

- It’s manufactured at Kuhn’s plant in northern France.

Kuhn has shortened overall coulter length on the Venta 330 by as much as 20cm compared with on the ‘big’ Venta 3030. “This will be exciting in min-till,” commented our test farmer when the power harrow combi was dropped off. Things actually proved to be exciting several times over when sowing cover crops, OSR and cereals last autumn, but not because of the coulters.

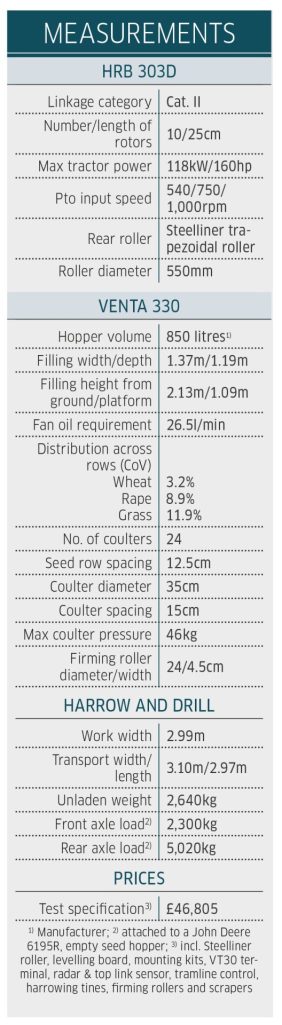

Kuhn developed the Venta 100 series as a lighter alternative to the well-known Venta 1000 (driving impression profi 7/2021). We mostly used our test unit with a New Holland TVT 145 (108kW/147hp rated power). This tractor coped comfortably with the power harrow drill, which tips the scales at around 2,640kg without seed.

In line with Kuhn’s naming strategy, the first ‘3’ on the 330 name stands for the working width, in this case 3.0 metres. The following ‘30’ tag denotes the Seedflex double-disc coulters. Kuhn also offers two other variants, the ‘10’ with Suffolk coulters and ‘20’ single- disc coulter.

Proven harrow

A familiar face is the HRB 303D power harrow with ten rotors, which is rated for up to 160hp. Biggest drawback is the total width, which we measured at 3.10m. This could prove to be a sticking point on some roads depending on where in the world you’re farming. Apart from that, the HRB 303 — as expected — did everything we wanted in both light and heavy, sticky soils. On the heavier ground, the HRB 303D was teamed up with another power harrow on the front linkage.

The rear roller was Kuhn’s ‘Steelliner’ strip roller. This has a diameter of 550mm and rings every 12.5cm to match the coulter spacing. This provides good load-bearing capacity whilst giving extra firming in the coulter path. A positive detail is that we never, even in wet conditions, had issues with soil building up on the roller.

Five-point linkage

The drill is coupled to the power harrow at two mounting points on the right and left, with the hopper sitting on the power harrow and the coulters on the rear roller. It is a bit of a spanner job if you want to remove the drill from the harrow.

The hopper is also connected to the power harrow headstock by a top link. In our view, it makes good sense to opt for the hydraulic version, as this allows you to raise the coulter bank by shortening the top link. This is not only helpful when just doing a harrow pass and not drilling, but also on freshly ploughed land, for example, when the tractor sinks in a little. In this situation, the ground clearance combined with the New Holland’s lift arm geometry and undulating terrain was, on occasions, too small.

Compact hopper

The 850-litre seed hopper holds just over half the capacity of the Venta 1000. Kuhn does offer a 300-litre extension as an option if you need to carry a bit more seed. Roughly speaking, an 850-litre hopper is enough for about 600kg of wheat seed. Drilling at a rate of 200kg/ha you would have to top up after about three hectares, which is OK.

The shape of the seed tank resembles that of a fertiliser hopper. The angle of the sides is steep enough for seeds to flow smoothly to the outlet, even when working on hilly ground. We think that the screen, which is designed to protect the agitator shaft and the seed metering unit from foreign bodies, could do with improving. Although it does what it’s supposed to, it is near the bottom of the hopper, meaning even tall people will have to stretch to open it. Plus, it doesn’t lend itself to carrying a couple of additional unopened bags of seed.

The level sensor can be positioned in two places: on the front wall of the hopper or, when drilling small seeds such as rapeseed, a little farther down on the left. Repositioning the sensor is done from the outside, even when the tank is full. Unlike the larger Venta, there is no separate low seed level warning.

Unfortunately, when the sensor was in the lower position, the low-level indicator often came on a little too late when sowing cereals, so we travelled several metres with the hopper empty. To avoid this, you are better off fitting the sensor in a higher position when drilling cereals.

The hopper opening measures 1.37m wide and 1.19m deep. The filling height from the loading platform is 1.09m, from the ground 2.13m — which makes for convenient filling with small or big bags. If you’re using seed in bulk, then just make sure the bucket width is suitable.

Familiar seed metering

The seeds flow from the hopper down to the metering system — the same as on the Venta 1000 and the TF front hopper. The metering unit wheel is adjusted on a crank to set the rate, which is from 1 to 430kg/ha, depending on the shape and size. You can see Kuhn’s recommended settings based on the seed size and rate on the operator terminal.

This worked well in oilseed rape and winter cereals during our practical test. However, the system had some difficulty with the 12 different sizes in our cover crop mix. When we followed the recommendation for the opening width, the cell wheel would stop for some inexplicable reason. When we opened the cell wheel wider, it started turning again. Drawback of using a higher application rate: we had to drive faster, which wasn’t always easy in the hilly valley fields although still manageable.

The seeds fall from the metering unit into the fan’s air flow, which feeds them through a 90° bend and a wavy riser pipe into the distributor head.

The fan requires around 27 litres of oil per minute. A throttle on the left-hand side of the machine allows for a coarse adjustment of the speed.

Seed distribution is so-so

The distribution head on the Venta 330 sits behind the seed hopper rather than inside it. This makes it easily accessible from the platform and also allows for shorter seed delivery hoses, hence eliminating sagging and slowing the seed flow.

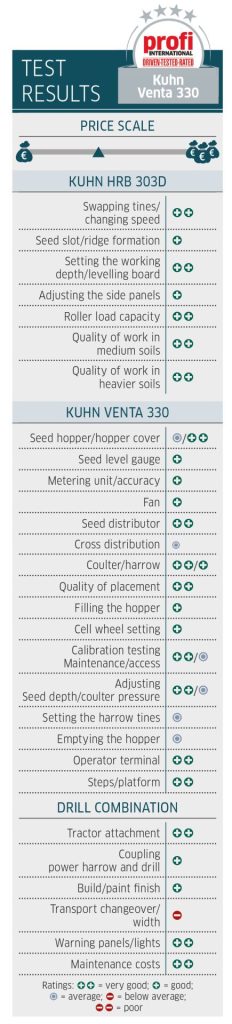

As we always do with our seed drill practical test, we measured the distribution across rows (see the graph ‘Cross distribution Venta 330’). The coefficient of variation for wheat was 3.2%, which is rated as ‘good’ according to the DLG evaluation scheme.

In rape, however, the Venta achieved 8.9%, which is only ‘sufficient’. With grass seed in the drill’s hopper, the 330 achieved 11.9% — something we can live with. For extra profi thoroughness, we also measured different seed varieties and found the coefficient of variation decreased when the thousand-grain weight decreased.

In the test field, all of the crops emerged satisfactorily. A half-width shut-off wasn’t fitted to the test machine, but this is on the options list. The 2 by 2 tramline control is standard, but we didn’t use it, because the test farm is organic.

Easy to fathom

As for combi control, we had the choice of operating either through the tractor’s main cab terminal or from the VT30 control unit supplied, so we tried both.

The VT30 control was a positive surprise, because its display has the same (ISObus) user interface as the tractor terminal and a number of extra buttons. This allowed us to operate the Venta without having to really study it — very good and in stark contrast to some other set-ups.

Another advantage of the VT30 control is that you can place it on the load platform for entering the calibration test results, for example. There’s no need to climb back on the tractor. The individual calibration testing steps are logical and easy to follow. Praise goes to the calibration bag, which is tared at the factory to 1kg, the standard scales and pull-out rack for attaching the scales.

However, criticism goes to accessibility of the metering unit, e.g. for attaching the calibration bag, for adjusting the cell wheel or for emptying the hopper, although these little niggles are due to the design. That said, some competitors have managed a more ‘friendly’ arrangement.

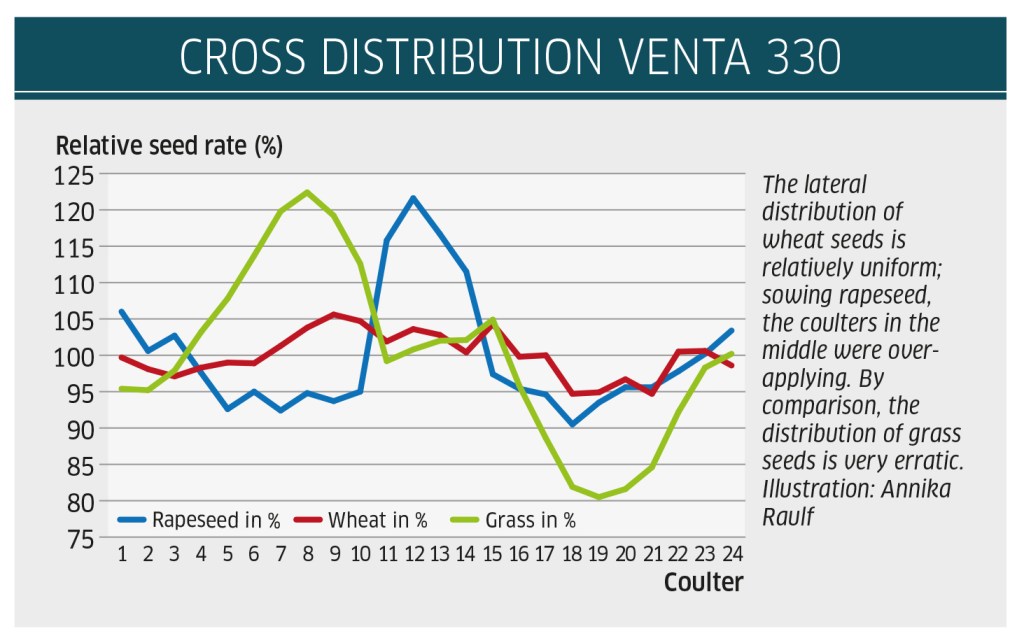

Short coulter

The Seedflex double-disc coulter with press wheel has long been a fixture on the Kuhn drills. The Seedflex 100 fitted to the Venta 100 is also used on the mechanical Sitera 100 (profi practical test 11/2022). Its main difference to the ‘regular’ Seedflex coulter is a shorter coulter spacing.

Diameter (35cm), disc stagger (41mm), seed feed in front of the disc centre and row-specific coulter pressure setting are identical on both double-disc coulters.

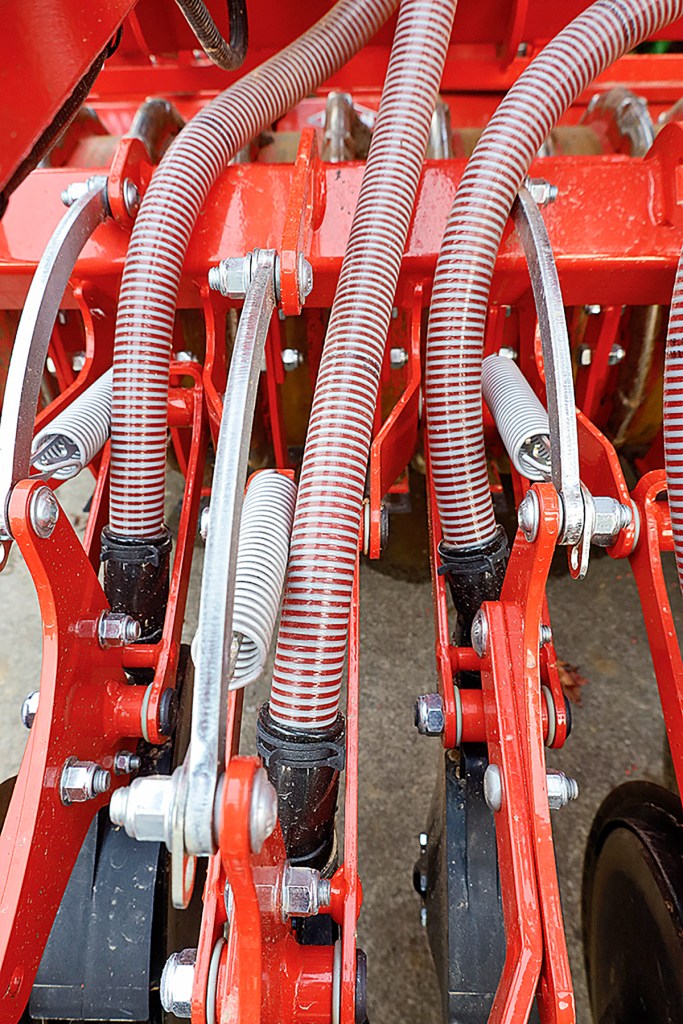

Kuhn says the maximum coulter pressure is 40kg; yet we even measured up to 46kg, regardless of the length of the coulter leg. The pressure is set by adjusting a spring to one of four positions. Refitting the springs on all 24 rows is tricky and time-consuming. We fitted the springs in position three and left them there throughout the test — there were no issues with the seed placement and depth control.

Incidentally, setting the seed depth is easy, with just one adjuster bolt on the right-hand side and one on the left, topped off with a laser-cut scale.

Blockages were not an issue despite the sometimes very trashy conditions and very moist soils last autumn. This is surprising for a machine on which coulters are spaced at 15cm and rows 12.5cm. Perhaps it’s down to the ring press that is running ahead and preparing the way for the coulters.

Summary

Costing a smidge over £46,800, the Kuhn combi with the HRB 303 power harrow and Venta 330 seed drill is a fair amount cheaper than many of the other brand models in this machine class.

Compared with the Venta 3030, however, the seed hopper volume and weight have been reduced, which during our test had no impact on the consistent quality of work. Technically, the 330 is on a par with its bigger sibling. Its big advantage is the relatively low lifting force and tractor requirement, which should make it an appealing option for small and medium-sized farms.

Andreas Holzhammer

For more up-to-date farming news click here and subscribe now to profi and save.