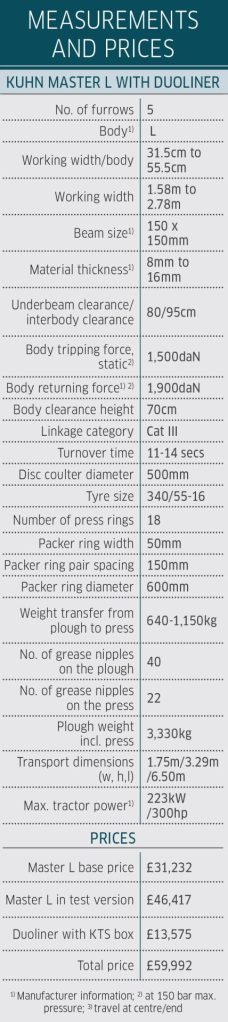

With an integrated press, stone protection and various hydraulic functions,

the Master L is one of Kuhn’s premium mounted ploughs. We used an ‘L’ last season to gain some first-hand experience.

KEEPING IT BRIEF

- The Master L is well built and easy to adjust.

- The advantages for the Duoliner press are offset by some disadvantages — you will need to make your own mind up.

- Auto-reset and an integrated press mean you need a decent lump of a tractor up front.

- Recently introduced Master M (with a 120mm beam) sits below the Master L in the Kuhn pecking order.

Ever since it was first introduced in 2018, Kuhn has added more and more options to the firm’s Master L mounted plough, which is nestled in between the long-serving Multi- and Vari-Master 153 and 183 models. Initially this answered Kuhn’s call for an on-land plough, with the in-furrow version of the four-, five- and six-furrow range following on a couple of years later.

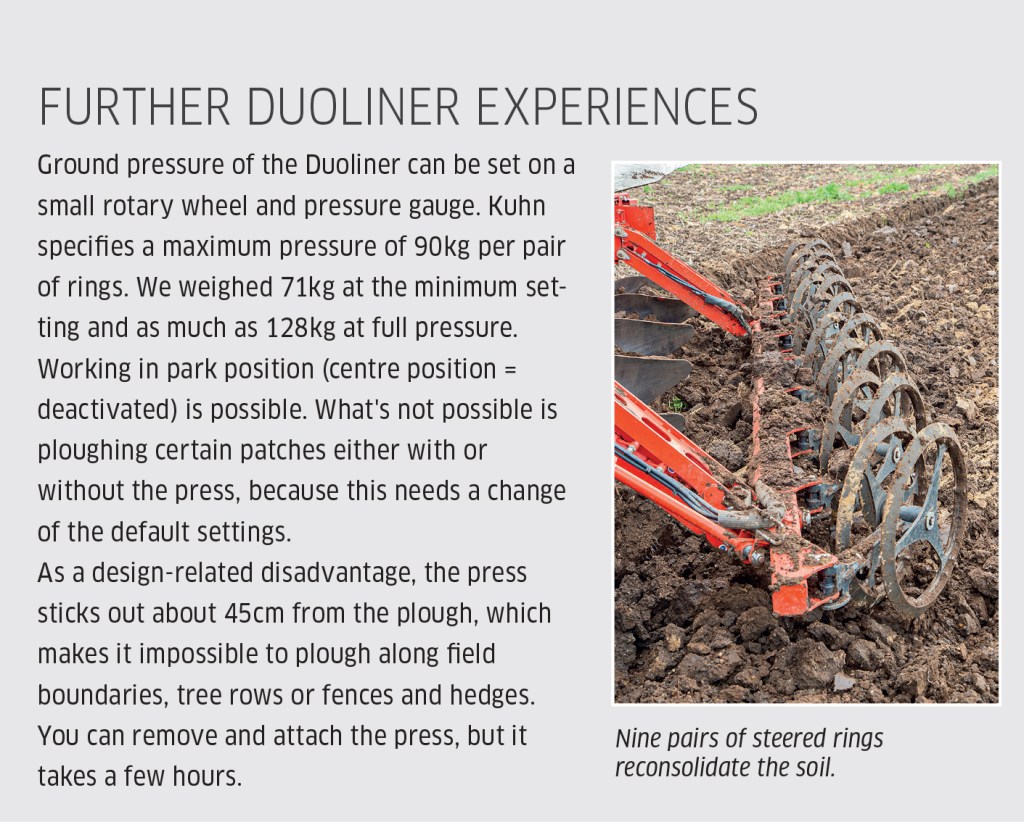

But the options list of possibilities is much bigger than in or out of furrow or if you want shear bolt protected legs or hydraulic auto reset. For instance, there are three different types of headstock (Standard, EasyDrive or OptiDrive variants), up to 12 different types of mouldboard and even the Smart Ploughing individual furrow section control for ins and outs. And on top of that there is the Duoliner integrated press unit with its 600mm plastic rings, which is only available on the Master L range.

For our test last season, we had a five-furrow Master L 5E (the E denoting it can be extended) complete with NSH hydraulic auto reset (£2,830) for tackling our stone-strewn light to heavy sandy loams. Mouldboard- wise it was sporting the L bodies, which proved their worth during the test. The L is pretty much the default fit in the UK for medium to deep ploughing while working with 710 tractor tyres.

Up front we had the hydraulic OptiDrive damper and the Easydrive top link unlocking system installed. We found the latter worked very well, although the damping isn’t really needed if the tractor already has an effective cushioning system.

There are several coupling heights for the different three-point geometries — these work well. The lift arms use Cat. III pins with IIIN or III spacings. A spring-loaded retaining bolt on the stand proved to be impractical in reality.

Double-acting plus LS

Two double-acting spools are enough to operate the plough and press. All of the functions (working width, turning the plough over, transport position, press width, etc.) can be preselected on the small control box, which keeps it nice and simple. You do need to have a load-sensing facility to maintain pressure on the press rings as they follow undulations.

The press asks for a combi wheel

Once you opt for the Duoliner press, then the combi work/transport wheel is part of the package for the Master L. A long lever, stored on the plough, is used for changing over from field to transport and vice versa. You do need a bit of muscle and dexterity to turn the wheel and insert the two bolts. Kuhn says they are going to address this in the medium term.

Our plough had the biggest possible wheel, a 340/55-16. A larger tyre would be great in the field but not for travelling on the road. Speaking of which, the plough is rated for up to 40km/hr; obviously this will depend on road conditions.

When in ploughing mode, the wheel sets working depth. The depth stop is adjusted hydraulically and is synchronised for both sides. Once Kuhn had done some initial fettling, it worked a treat. The easy-to-spot depth scale could do with being longer as the Duoliner takes so much of the weight that the scale is in the lower third when ploughing 20-30cm deep.

The road lights stay on the plough, a great solution. Once you reach the field, they are folded down and pushed into a forward position. Now if Kuhn could come up with a similar solution for the warning sign on the press it would be the cherry on top.

Convenient set-up

The hydraulic adjustment options for the working width, angle and front furrow width are convenient. With the exception of the line of draft, all parameters can be easily set from the cab and read on a scale. Kuhn keeps things old school with measurements shown in inches which had our German colleagues in a state of confusion.

Overall, we were impressed by how well the furrow was cleaned out, the plough’s overall performance and how it incorporated the organic matter. Although we made numerous tweaks to get the set-up right, we couldn’t achieve perfectly level match-ups; there was always a slight difference between passes. Kuhn reckons this may have been caused by the mouldboards needing a bit of adjustment. However, there’s a chance it was also caused by the press, which overlaps at the front. The bulky mounting bracket for the press obstructs your view of the first furrow, too.

Weight to be considered

The advantages of an integrated press (no second tractor required when moving from one field to another, immediately ready to go) are offset, above all, by the additional weight.

Our plough and press weighed 3.3 tonnes, which meant our steed, a Fendt 728 Vario, had two tonnes of ballast up front. Also, the tractor must have the lifting power (and permissible axle loads) to cope.

Other nuggets of information

- The Master plough turns over smoothly.

- There are 40 grease nipples on the plough and 22 on the press.

- The auto-reset has 70cm of breakback travel.

- The working width of the plough and press are not altered in sync — which Kuhn says can be an advantage when dealing with poles in the field or other obstacles. We reckon it is a disadvantage because there is a risk of a collision when the press is narrow and the plough wide.

- The points are reversible, and the height of the landsides can be adjusted depending on the ploughing depth.

- The price of the five-furrow plough starts at £31,232. The press costs £11,840, the KTS10 box an extra £1,735 The price climbs to £59,992 when the cushioned combi wheel, lights and other options are added.

Wrapping it up

The Master L made a stable and mature impression in the field and during set-up. We’d have preferred the option of being able to operate it via ISObus and full load-sensing hydraulics, as this would allow operators to save default settings both for using and not using the press.

There’s no denying it’s a hefty lump of metal with the press attached, the plough is rated for 300hp, and you will need tractor not far off that to comfortably handle it. The finish is largely convincing. The firming action of the press is usually sufficient for ‘mid’ soils, depending on your needs and wants.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.