For its high-capacity trailed mixers, Siloking now has a continuously variable transmission, which means stalling is now a thing of the past. We explain more.

KEEPING IT BRIEF

- On its larger diet feeders, Siloking now offers a power-splitting gearbox.

- This new gearbox minimises the load on the tractor’s pto.

- Operators can programme three auger speeds — chopping, mixing, emptying.

On tub mixers with three augers and capacities of more than 30m³, the torque needed to get things moving can be demanding on the tractor — indeed, on occasions, this load is enough to stall the engine. A modern solution seems long overdue, especially in today’s world of continuously variable transmissions, and this is exactly what Siloking has done.

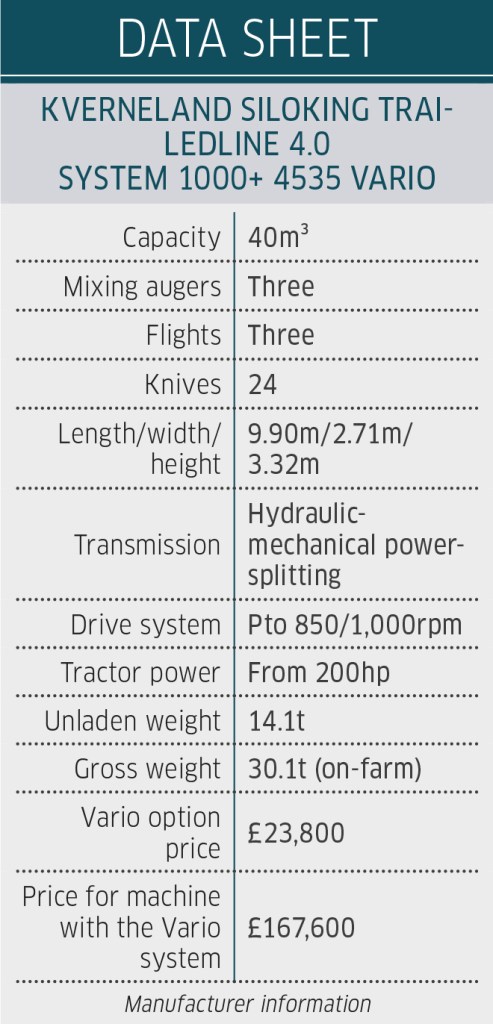

We were able to check out one of these diet feeders with the new driveline in action at the Fromajgard farm in Denmark (more about them on page 32). Every day, around 40 tonnes of feed is mixed for the 1,450 animals, which for the past six months has been done with the not so snappily named Siloking TrailedLine 4.0 System 1000+ 4535 Vario. Moreover, the model name is nearly as long as the colossus itself: 9.90m long, 3.32m high, an unladen weight of just under 15t, 40m³ volume, three mixing augers with three flights each and a permissible total weight of 30t.

After operator, Bjarne Sorensen filled the seven ingredients into the tub, the scales showed a load of 15t. You can imagine how the tractor feels when asked to engage its pto clutch and persuade those three augers to start moving again.

Stepless with two steps

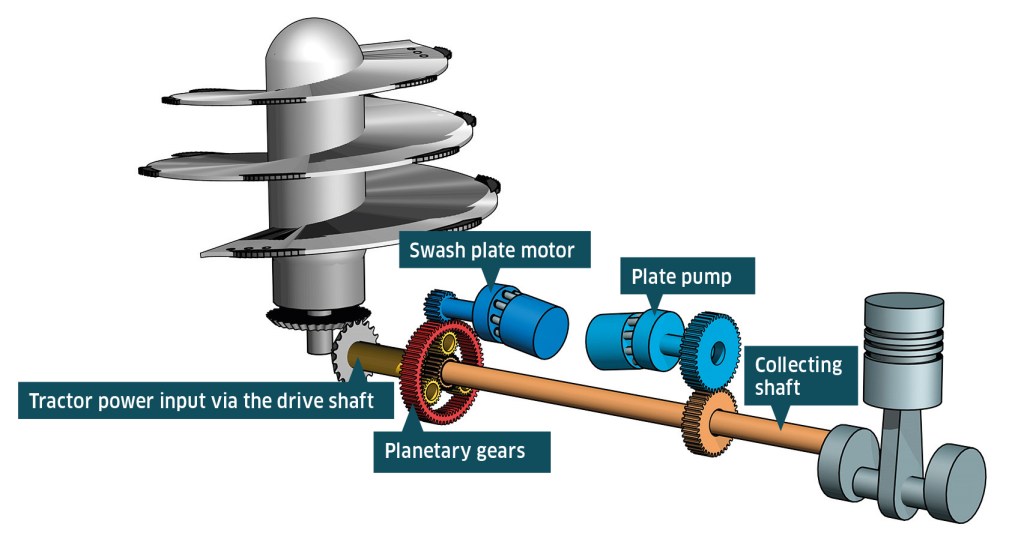

This is where the new Vario option comes into play. Together with VDS, an Austrian specialist for continuously variable drive systems, Siloking has developed a bespoke power-splitting gearbox for its big feeders.

The basic principle of the CVT is the same as that in a tractor: a planetary gearbox keeps the gears permanently in mesh. By braking or accelerating the inner sun gear, the planet carrier or the outer ring gear, it is possible to alter the output speed under load. And just like on a tractor’s stepless transmission, it combines mechanical and hydraulic power.

Operators can program in the three most frequently used auger speeds on the control box menu: 33rpm for chopping straw and silage bales at the start; 15 to 25rpm for mixing; 55rpm for completely emptying the tub. All speeds are infinitely variable!

You have the option of being able to switch between the first two speeds, the machine doing the loading. With a constant tractor engine speed, the gearbox will automatically alter its ratios to speed up or slow down the augers and achieve the desired speed. This is shown on the screen with a turtle, hare and ++ symbols. When the symbols flash yellow, the gearbox is increasing the auger speed to the target speed. When the symbol is permanently green, the target speed has been achieved.

The transmission’s efficiency sweet spot (where it has the lowest amount of hydraulic interaction) is when the pto is spinning at 850 to 900rpm and the mixing augers are working at 18rpm. It should be no surprise to learn that this is exactly the speed range where the mixer does most of its work.

Smoothly from zero to full load

For a ration for high-yielding dairy cows, the mixer was filled with seven ingredients. After about 10mins of mixing, a homogeneous ration weighing 15t was ready to feed out. On the Danish farm, the 30t Siloking was powered by a 180kW/240hp New Holland 8970. To ensure it doesn’t stall while on route to the barn, the pto is knocked off and then re-engaged when at the feed fence.

When the pto input speed reaches 850rpm, the augers can be switched on. The swash plate pumps swing out slowly from their zero position and the augers start to rotate very slowly. It all happens so gently that the driver hardly notices! The stepless gearbox accelerates the augers slowly until they reach the target speed.

The mixed ration is discharged through two huge heavy-duty guillotine doors (120 x 80cm), one of the options on this machine that the farm opted for. Unlike powershift transmissions, there are no momentary shockloads in the driveline.

Integrated overload

The gearbox sits in the drawbar of the large mixer feeder. Two electric oil coolers are mounted on the right side. The tractor needs to have an ISObus socket in order to provide the necessary electrical power for the fans.

The oil should be at 12 degrees for minimum viscosity. This means, in cold winter months you’ll need to wait for the oil to warm up before you can activate the augers. Users explain the easiest way to do this is to drive from the barn to the clamp or loading area with the drive engaged (around 450 pto rpm), allowing the circulating oil to heat up and be warm enough by the time you arrive. The operating temperature is approximately 80 degrees, and the oil change interval is every 500 hours.

Siloking says the hydraulic system pressure is monitored to prevent overloading, while the pressure in the gearbox is checked to prevent excessive torque.

Maximum input power is 180kW/240hp. If there is a higher level of torque, the control system detects the increasing hydraulic pressure and the gearbox automatically reduces the auger speed. This not only protects the gearbox, but also the following components such as the pto shaft or right-angle gearbox under the augers. These still have shear bolt overload protection, just like the conventional gearbox model.

Other details

- The tub is equipped with the Siloking Data System. This allows operators to select programmable recipes, a fill programme and hydraulic functions remotely.

- The weighing system can be monitored in real time via a tablet or smartphone.

- According to the maker, Siloking’s Feeding Management Software is compatible with other herd management programmes for sharing data.

- The augers on our machine were coated with the optional stainless steel alloy, Silonox. The lower part of the tub wall can also be lined with Silonox too as an extra option.

- The feeder’s tridem axle is equipped with self-steering. Forced steering is an extra-cost option.

- The opening width of the two sliders is displayed electronically on the control terminal.

Summary

The proven advantages of a power-splitting transmission can be fully exploited with the Siloking Vario system.

The smooth drive system is certainly a plus point for both tractor and mixer, while the power-splitting gearbox makes for a smooth auger start once the tub has been filled, not to mention the option of being able to set three different auger speeds.

The Vario system is available as an option for the large TrailedLine models System 1000+, Premium 3022 and Duo Avant 3227 and in the Kverneland UK price list costs £23,800 more than the mechanical two-speed gearbox. The mechanical gearbox can’t be shifted under load.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.