Lely unveiled the Exos autonomous zero grazer in 2020. Now it’s officially on the market in parts of Europe, we were able to catch up with one of the first commercial models.

KEEPING IT BRIEF

- The Exos mows, transport and feeds fresh grass autonomously.

- It also fertilises the cut pasture while in the paddock.

- Lely offers remote support, which is claimed to resolve about 80% of issues remotely.

Five years ago, the Exos autonomous grass harvesting robot was part of Lely’s Yellow Revolution, the banner under which it launches all of its new products. The electric-powered machine is able to mow, transport, fertilise and feed fresh grass completely autonomously.

Experiences

In 2024, Lely operated 17 robots, one in Germany and 16 in the Netherlands. In total they harvested about 22,000 tonnes of fresh grass, completing more than 24,000 trips autonomously across 3,736 working days. On average, each farm was able to cut fresh grass for 230 days, feedings its cows between 3.1 to 9.8kg of dry matter grass per day.

Requirements

Lely recommends having over 35 hectares of grassland close to the cow barn, and the system is best suited to herds of 150 to 400 cows. And because it is a fully autonomous vehicle, the Exos needs to stay at least 5.0m away from public paths and roads. A 4G internet connection for the GPS correction signal is also needed, as is a 3.50m minimum overhead clearance in the barn.

Market analysis within the Netherlands has demonstrated that 36% of the approximately 16,000 Dutch dairy farms are suitable for the Exos, so around 5,760 farms. Lely still has to do similar analysis in other markets as well as working on legal solutions that will allow the Exos to cross a road, which should strengthen its appeal to many more farmers.

Setting up the auto system

Once the fields and routes to the fields are mapped using GPS, ‘hard boundaries’ are programmed that the Exos cannot cross. Then the feeding areas inside the barn and the quantities to be fed in these areas can be set up. The charging station is mounted on a paved surface and then connected to both a power supply (400V/3 x 16A) and a water supply.

The Exos

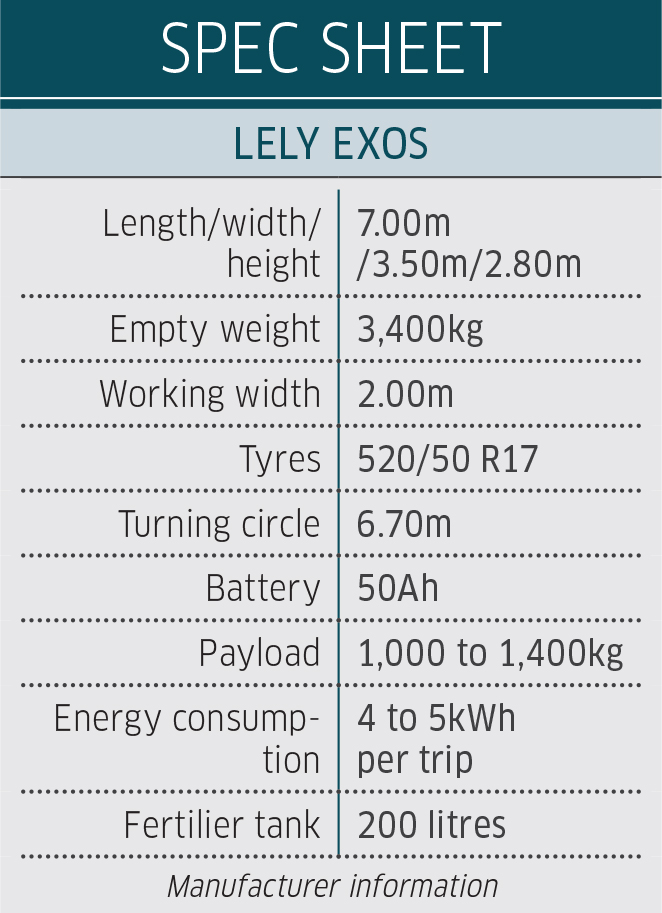

The Exos uses a 2.0m wide cutterbar that is guided by a roller for height control. The cutting height can be continuously adjusted mechanically. Freshly cut forage is gently fed into the loading area by an elevator with plastic slats to minimize nutrient loss and prevent the plant stem getting damaged. A sensor monitors the filling level, but there are also weigh cells under the hopper to measure the amount of crop harvested with each load.

A spray bar for liquid fertiliser is linked to the height control roller. There is enough on-board storage for 200 litres of liquid fertiliser that is automatically filled at the docking station. The maximum application rate is 50kg N/ha, and the liquid fertiliser can be diluted with water.

A cross conveyor and two metering rollers place the forage along the feed fence. The Lely robot doesn’t yet have the capability to determine the dry matter content or nutritional value of the cut grass. And in rainy or dewy conditions, it is not easy to alter the feed rate to compensate for the higher weight of the load. All you can do, is increase the number of trips. The Exos can hold up to 1,400kg of fresh material.

One round trip takes about 1.5 hours at a speed of 2 to 4 km/hr. Empty, the robot weighs 3,400kg, and each wheel has its own electric motor; steering is controlled by two centrally articulated axles. The battery has a capacity of 50Ah, which takes 15 to 30 minutes to charge.

Communication with automated feeding

The Exos can only be used with the Juno Max feed-pushing robot or Vector feeding robot. The standard Juno isn’t compatible because it can’t communicate with the Exos. This pusher cooperation is an essential part of the jigsaw because it is one job the zero grazing machine can’t do; nor can it measure the amount of forage already at the feed barrier.

To avoid congestion at the feed trough, the Exos communicates with the other mobile units. There is a designated waiting position in front of the barn where the Exos parks up until the Vector feeding robots reach the feed kitchen. Documentation and control are handled via the ‘house my farm’ software – either from the PC or smartphone app. Settings can be changed, data evaluated, and alarms processed. In the future, the Exos will also be integrated into the Horizon herd management software to simplify control and documentation.

Safety

A stereo camera monitors the area in front of and behind the machine. We tested these cameras several times during our test, and they worked reliably. In-barn navigation is done with ultrasonic sensors, while collision sensors stop the machine if it encounters obstacles.

An important aspect is wildlife detection: larger animals such as deer or hares are detected by the cameras. Bird nests, for example, must be detected by the farmer by using, say, a drone, and stored to the system. According to Lely, fawns are not a problem, as the low growth on the pastures keeps the deer away.

Although the unit is ready to go to market, customers have given the development team lots of feedback. There are plans for integrating a feed analysis, especially DM content as well as yield mapping. Wildlife detection, too, is to be improved.

Prices and costs

Lely has not yet set a specific price for the Exos. Initial estimates suggest it will be in the region of €250,000 plus €5,000 for setting it up. The annual maintenance costs are €7,500. In the Netherlands, there is a knife sharpening service that costs €1.25 per trip to the field. Whether this service will also be available here is not yet clear. Each load of grass requires 4 to 5 kWh of electricity (approx €1.50-2.00, depending on the electricity price).

Summary

The Exos is unique on the market. However, due to specific requirements, the machine is not suitable for every farm. Lely will make further adjustments in the near future, to make the device smarter.

The Dutch company has clear goals: by 2025, 30 machines will be in operation and 30,000 tonnes of fresh grass will be cut. Three to four of these machines will be operating in Germany but it is not being offered in the UK, at least not yet.

Sebastian Rüther

INTERVIEW WITH VINZENZ DICKEBOHM

My name is Vinzenz Dickebohm. Together with my father, I manage the Dickebohm farm here in northern Germany. We milk 300 cows and our barn is equipped with milking robots, feeders and slurry scrapers. In addition to a number of part-time staff, my mother also works on the farm. My wife is a large animal vet.

How much land does the farm have?

Vinzenz: We farm 270ha, of which about 180ha are grassland.

How did you come to own an early Exos?

Vinzenz: I’d had the idea of feeding fresh grass for a while, as we are in an ideal situation with fields just behind the barn. We were also looking for an alternative to soybean and rapeseed as a protein source. Lely contacted us, and we liked the concept. Then everything happened very quickly.

Why not just graze?

Vinzenz: With so many animals, grazing isn’t an option for me. The animals would quickly trample the grass. Besides, it would involve a lot of extra work, and combining grazing with high-yielding cows on robots is not straightforward.

How did the set-up go?

Vinzenz: It was quick and simple. Lely measured the fields with a quad bike that was equipped with a GPS receiver and then entered the data into the system. They did the same for the barn and access roads. We then installed the charging station and that was it. The Exos was put to work.

How much fresh grass do you feed?

Vinzenz: We started with three runs per day to get the animals used to the feed. Each week, we increased the amount by one or two trips. We have now settled at nine trips. We expect to cut about 200kg of dry matter per trip. The Exos holds 1,000 to 1,400kg of fresh material with a dry matter content of 16 to 20%. So, we feed around 5.5 to 6.0kg of dry matter per animal per day.

How often do you adjust the ration?

Vinzenz: The grass is sampled every 14 days. Currently, we are feeding about 20% dry matter and 7 MJ NEL/kg dry matter. We adjust the feed rations weekly, but this is usually just a small tweak. We draw conclusions primarily from milk checks and dairy values.

Do you receive any premiums for feeding fresh grass?

Vinzenz: The local dairy does offer premiums for pasture grazing, but unfortunately not for feeding fresh grass, at least not at the moment.

What is the milk yield?

Vinzenz: Milk yields increased slightly as a result of the change. Currently, we’re at 34 to 35 litres per cow per day. The composition is excellent at 3.4% protein and 4.1% fat.

How about the feed intake?

Vinzenz: Initially, the intake increased dramatically, and the cows were eating fresh grass in addition to 28kg of feed. Now they eat about 21 to 22kg of feed plus 6kg of fresh grass per cow per day.

How has the ration changed?

Vinzenz: The ration consists of maize and grass silage, rapeseed meal, soybean meal, and corn flour. We were able to reduce the amount of rapeseed, maize and soybean meal by 4kg.

Do Exos and Vector get along well?

Vinzenz: Both systems work well together. The Vector measures the height of the feed in the passageway and then decides when to feed — in our case, this means currently at a height of 12cm. The system regulates feeding automatically, and the Vector also pushes in the feed regularly. It works great.

Is animal health changing?

Vinzenz: No, I haven’t noticed any significant differences so far. Neither worse nor better.

Has the sward changed?

Vinzenz: Thanks to regular mowing and a longer stubble length of 8 to 10cm, the grass grows significantly faster, and the sward has become denser. We don’t drive the same tracks in the grassland. However, we do overseed our fields in spring, spreading 10 to 15kg/ha each time. We also lime every year!

How do you fertilise the fields?

Vinzenz: In February, we apply separated slurry using an umbilical system. After that the Exos fertilises the fields with UAN. Each field is harvested by the Exos every 20 days. I think there is too high a risk using slurry applications with such a short window between cuts.

What is your biggest challenge?

Vinzenz: Developing a feel for the growth. First, the geese grazed our grassland really short, then the grass suddenly became too old for zero grazing. Now, due to the drought, growth is slowing down. You have to keep an eye on all these special aspects — that’s only possible if you regularly check your fields.

Your conclusion after eight months with the Exos?

Vinzenz: I’m very satisfied. Feed and harvest costs have decreased, while milk yield has increased. Fresh grass feeding is almost automatic and demands little work. However, it takes about six months to master the art. Regular field checks, once or twice a week, are important to monitor the crop and adjust the strategy.

One disadvantage is that the Exos leaves wheelings where there are no roadways to the fields. Also, the animals consume more liquid from the grass. This results in more thin slurry. As a result, the barn and the animals are a bit dirtier. That’s why we’re considering purchasing a Lely Collector.

For more up-to-date farming news click here and subscribe now to profi and save.