With ultra shallow cultivators seen as one of the ‘in’ things, Lemken has strengthened its Koralin range with a new fully mounted model that we had the chance to try out last summer.

KEEPING IT BRIEF

- Unlike the semi-mounted version, the fully-mounted Koralin doesn’t have leading discs.

- Even in patches of dense trash, the cultivator never bunged up.

- Appears to be a very efficient way of creating a full working width stubble chit.

- Changes implemented to the semi-mounted model since our 2022 practical test are highlighted on page 32.

To tick even more boxes, Lemken has decided to expand its Koralin range of ultra-shallow cultivators with a fully mounted model. We already got to know the semi-mounted machine when we ran one for a season and published our findings in the profi 5/2022 issue.

The new 9 K and 9 KU (shearbolt and auto-reset tines) use the same tine design and wide working shares to move all of the soil across the 6.60m width, but they lose the two rows of leading discs. And, of course, being fully mounted they have no need for any running gear.

Three rows, two shares…

We were able to see what this latest Koralin is capable of in late summer on two different occasions. First time out was in untouched stubble a few weeks after harvest. Then our next outing was into a previously cultivated stubble field with a strong stand of field pansies.

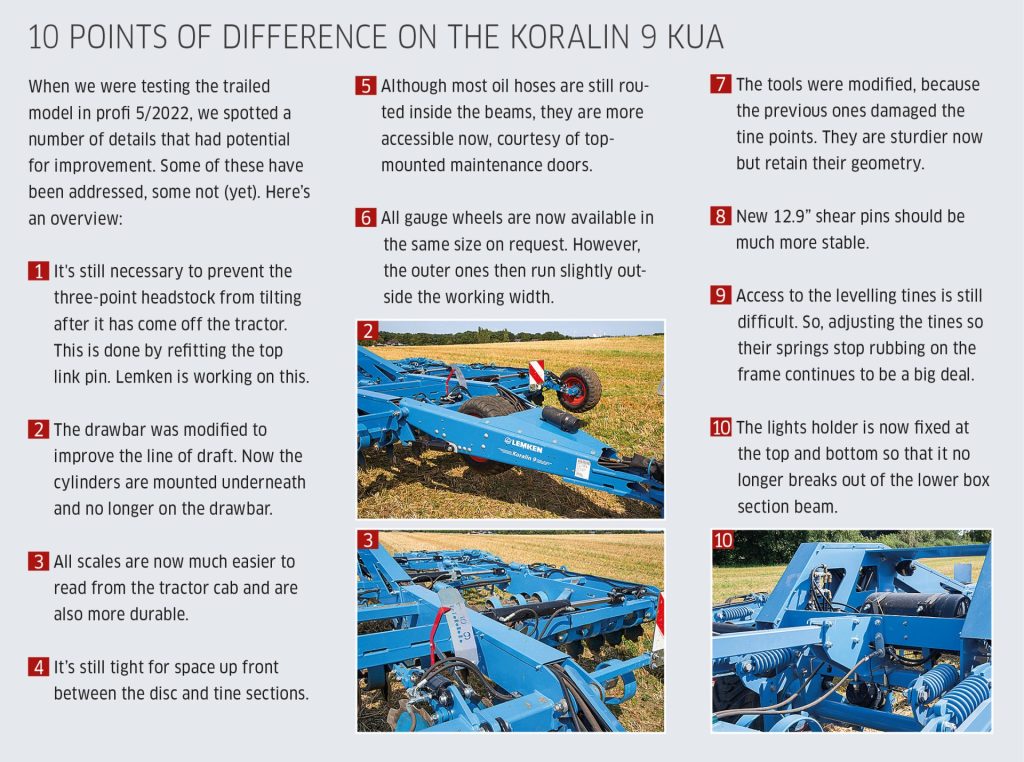

Both test fields were sandy and very loose. Predictably, in both scenarios, the Koralin performed well, almost always leaving a flat, even finish and never clogging. This is thanks to the amount of clearance between the three rows of tines, a generous 1.0m apart. It’s only behind the Cat IIIN headstock that the frame is positioned slightly outside the grid to ensure symmetrical tine spacing and that a point is hitting the ground every 30cm.The tines themselves are available with shearbolt (9 K) or spring auto-reset (9 KU) protection.

Standard fitment is a 38cm wide duckfoot share, which can be supplied with or without carbide for longer service. These shares result in a 4cm overlap on both sides. With these, the tip only slightly digs in the ground so the soil can flow over the wings.

Alternatively, there is the 38cm wide Trimix share, which is more targeted at seedbed preparation in heavier soils. Both of the foot options use the toolless quick change fitting system shared with the Kristall.

The 15mm wide tine legs do have a tendency for collecting longer plant residue. This may sound like an issue, but it never caused any problems in our conditions. Worn legs can be replaced after undoing two bolts.

Top-notch depth control

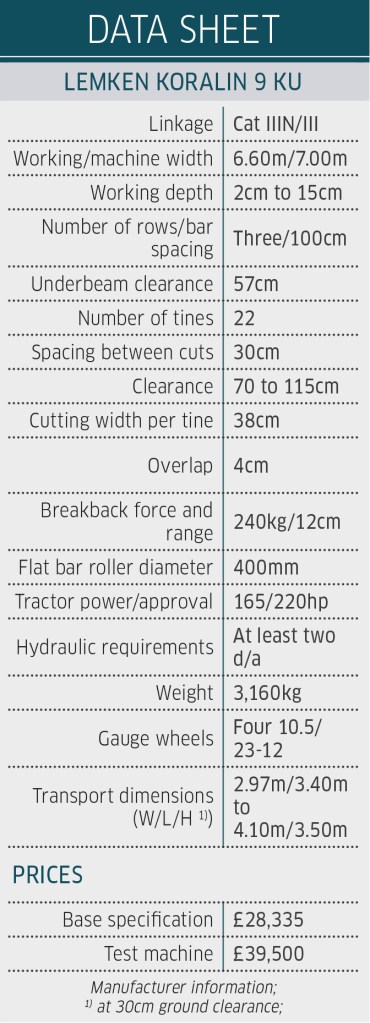

The Koralin is designed for working depths between 2cm and 15cm. The depth is set using four gauge wheels (10.5/23-12) that run within the tine section. These wheels are also hydraulically interconnected through a master/slave system. Floating pistons also allow the frame wings to adapt to contours in hilly fields. A laser-cut scale shows the current depth setting.

Consolidating or harrowing … or both

The tines are followed by a lightweight single or tandem crumble roller, which, in turn, is followed by one or two rows of 10mm harrowing tines that are spaced at 12.5 or 25cm. Lemken says the arms on the following harrow are due to get a design change … and we agree. Ideally it should be possible to tweak their angle and depth separately, though likewise the fastening clamps that attach the tine bars to the frame shouldn’t slip out of place.

If you don’t want the rear roller, then it is possible to have four rows of following tines, and these tines also benefit from hydraulic adjustment.

Our impression and summary

The Lemken Koralin 9 K cultivator with shear bolt tines is particularly interesting for shallow, intensive soil tilling. We were impressed by the quality of work in terms of soil movement and levelling — both at a working depth of 2cm and 12cm.

Operating the machine from two spools is simple. Weighing around 3.1 tonnes and with a length of up to 4.10m, the implement will challenge some tractors, especially in terms of lift capacity and rear axle load. On our Massey 7S.180, we were working with a 1,000kg front weight, and there was a 10.5t load on the back axle.

For now there is just the one working width of 6.60m available, and the base machine costs £28,335. The optional extras on the machine we used, bumped this price up to £39,500. In our view, the mounted version helps Lemken reach a much larger audience than the semi-mounted alternative — wide shares for the masses in other words!

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.