Operator-focussed changes encouraged our featured test team to invest in Massey Ferguson’s 8S.265 complete with Dyna-7 transmission. After four years and over 4,400 hours, how has it fared?

KEEPING IT BRIEF

- Plastic cab steps prone to breaking

- Trousers can snag on toolbox clips

- Control box rail simplifies positioning

When it was revealed in 2020, Massey Ferguson’s 8S was unlike anything the firm had ever produced. Top of the innovations was the Protect-U cab/engine installation creating a 24cm gap between engine and an all-new cab with negative rake windscreen, to insulate the operator from heat and noise while lowering in-cab noise levels to 68dB(A). Impressive stuff.

The press release profoundly claimed that the 8S represented a new era of straightforward and dependable tractors, delivering exactly what operators want. But for every operator who loves them, there seems one who also detests them, in other words it’s a bit marmite.

From new

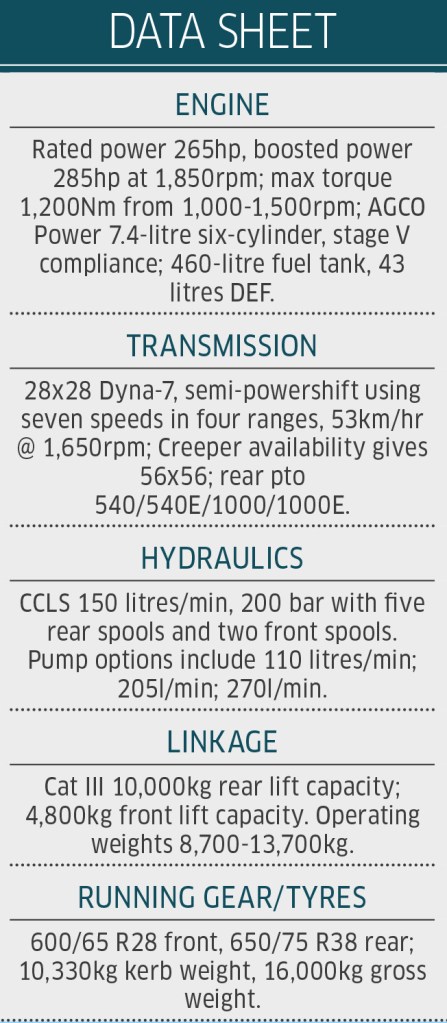

Initially, the 8S included just four models starting with the 205hp 8S.205 and topping out with the 265hp 8S.265. EPM (engine power management) with the 7.4-litre AGCO Power Stage V, six-pot engine topped each one up by 20hp. Since then, the range has been extended with 8S.285 and 8S.305 versions.

Two transmissions were offered at launch – Dyna E-Power dual clutch or Dyna-7 semi-powershift transmission. The latter was based on the proven Dyna-6 but re-engineered to gain an extra gear. This pushed ratio choices up to 28 speeds in both directions, through seven powershifts in four ranges.

Massey’s Dyna VT continuously variable box still was some way off arriving in the 8S, with the two powershift boxes claimed to reduce power losses by 26% and improve fuel economy by 10%. Indeed, in our 10/2022 profi tractor test with an 8S.265 Dyna-7 low fuel consumption was a big plus point of the new tractor range.

Precision farming connectivity was a big deal too, and you could choose from Exclusive or Efficient spec levels.

Who have we here?

To get a true perspective of how the 8S has performed, we visited a mixed contracting operation that currently operates a pair of 8S.265’s in Exclusive specification. While the newest is a two-year old Dyna VT version with little more than 2,000 hours on its clock, it is the four-year old Dyna-7 model with over 4,400 hours on its clock that arrived first, and falls under our spotlight.

Our test crew is no stranger to the MF brand, having jumped upwards from 160hp 7716 models to the 260hp 7726 version, before biting the bullet with the ultra-modern looking 8S for its varied agri-business. Tasks include mowing, raking and tedding, plus a round baling workload that nudges over 15,000 bales per year with a combination baler wrapper. Square baling features too, with over 5,000 bales made yearly.

The firm also gets stuck in with maize ground preparation, plus other arable tasks, with a six-furrow reversible plough and 6.0m folding power harrow among the seedbed-making favourites. It was important to operate two tractors of the same power and specification, so that any of these frontline tractors could be capable of handling any job that came up.

Front linkage and pto suits a front/rear mower combination, and the linkage makes it easy to add or remove front weight boxes too, and rear wheel weights add up to half a tonne of ballast. All can be easily removed, slicing kilos off the tractors when there’s a need to tread lightly on top-work.

First in the door

The first 8S.265 arrived as a dealer demonstrator with just a few hundred hours on the clock, it immediately made its mark on the team, with one operator falling for it almost immediately. There was temptation to look at other brands, simply for a more spacious and comfortable cab, but the 8S had everything and more that this team was looking for.

But while our host wasn’t quite ready to swap the first of his 7726’s, a tempting deal along with a healthy warranty and servicing package did wonders to tip the scales in the direction of helping the 8S.265 to stay put.

While the 650 R38s do appear small, ploughing in-furrow on heavy clay meant 710s were a no-go for matching up furrows and also threading the tractor down narrow lanes. Amber beacons have been knocked off by trees in the past, so making the tractor sit taller and wider on 710 R42 tyres was a route less favoured.

First impressions of the tractor were – and still are – great. The cab space, comfort and low noise levels are among the top box ticks delivered by the 8S. And four years in, that opinion hasn’t waned thanks to the spacious cab and low noise levels.

While transmission choices were limited in the early days of the tractor, our test team weren’t concerned or disappointed with the lack of a Dyna-VT option. Past experiences of Massey’s continuously variable transmission in previous models were found not to be as user-friendly as the dependable powershift. So, the Dyna-7 was the go-to, and button-bashing on the Fegrie’s joystick an easy route to tractor control for all involved.

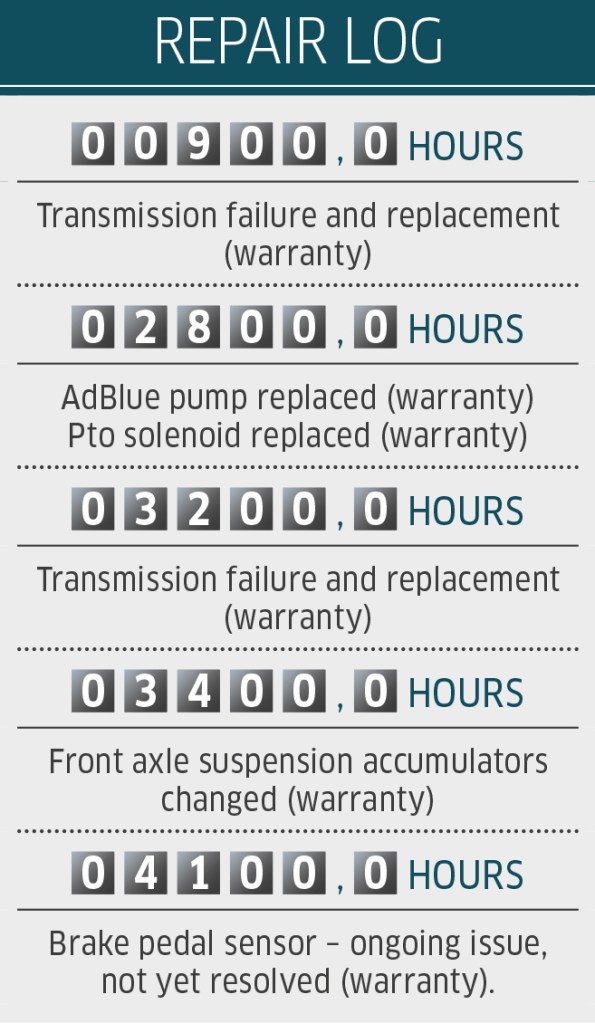

It happened

At 900 hours, the Dyna-7 transmission failed, and the extended period of analysis at the dealership meant the 8S.265 was out of action for a few months. A loan tractor kept the firm fully operational, and with the security of warranty, the impact on the business was minimal.

Speaking to those in the know, it seems clutch pack-derived failure is the most common weakness. Massey Ferguson has developed a modified part which is supposed to resolve the issue.

Operators noted that the Dyna-7 transmission had always been a smooth-shifter, and was easy to use too, flicking through ranges and powershifts to suit, along with pre-selecting start-up gears.

Tractors are generally run up to almost 6,000 hours before they are changed, keeping some warranty that can be transferred to the new owner. This usually happens within a three-to-four year cycle, and with owning and operating costs fixed through a service contract and extended warranty package, it’s proved a great way to avoid hidden surprises.

However, the big MF’s decision to eat its way through a second Dyna-7 transmission saw the 8S on yet another extended sabbatical at the local dealer. It perhaps explains why the tractor is still on the fleet, having failed to clock up its allotted warrantied hours in the usual timeframe.

It’s not a problem for the test team, and it’s not caused the operators to want to turn their backs on the brand. Quite the opposite. With warranty still in place for another 1,500 hours or so, the tractor has almost another year with the business before it is expected to be replaced by… yes, another 8S. Next time though, it will be a Dyna-VT.

Not that the crew has any reservations over the Dyna-7, given the support they’ve had. It is all down to the improvements made in the performance of the latest generation of stepless box, which our test team found out when seeking a replacement for its second 7726 Dyna-6.

All admit they would have stuck with another 8S.265 with Dyna-7. But having re-acquainted themselves with the stepless transmission, the test team decided that its extra cost would bring fuel savings and efficiency benefits to the business.

It has also given an opportunity for the powershift-favouring older generation to understand and appreciate the convenience of a CVT in pedal-mode, compared to constantly nudging the joystick.

With combination baling and wrapping tasks, or tugging the big square baler, it was felt that the Dyna-VT offered greater efficiency gains on the longer climbs. Rather than going down a gear with the Dyna-7 and losing around 3km/hr forward speed, the Dyna-VT’s stepless adjustment could help the 8S to hold onto its pto speed and wash off much less forward speed to maintain output on those long climbs. That said, the Dyna-7 features a brake-to-stop function, activated by switch, and is considered a huge benefit with the repetitive process of start-stop during round baling.

Size and niggles

For such a big tractor, manoeuvrability is given a big tick, with levels of agility to embarrass smaller machinery. Ride comfort is also a positive for those spending long days in the cab, though all have commented on the ignition key’s poor location, which is easy to bend when leg and key collide. The short-term solution is an ignition key that is designed to fold at the fob, longer term, all agree that it needs to be relocated.

Inside the cab, the 8S has few short-comings. Our operators like its all-round view from the four-post cab. Those in the seat also praise the generous seat rotation, making it easier and more comfortable to watch what’s going on behind. However, this generous seat swivel has resulted in the right-hand side window’s wiper motor assembly being removed from inside the cab, as it could collide with the armrest-mounted tractor terminal when the seat bounced.

The 9in Datatronic 5 touchscreen terminal is also given a big thumbs up by the test crew, as is ISObus connectivity with several of its implements. The simplicity with which spools can be swapped around, along with tweaking flow rates and timing of spool functions, is considered a delight. But ask the terminal to do too much multi-tasking and a freeze would happen with alarming regularity.

The solution was found to be the installation of a second terminal – and this has been done on both our team’s 8S models – reducing the need to toggle between guidance screens and tractor functions, and solving the screen lock-ups.

An A-post colour display is easily personalised too, and also shows the climate control settings that can be tweaked using short-cut buttons on the armrest.

Joystick control is considered easy and low effort, and despite the dirt that can accumulate inside cabs where operators are frequently in and out of the seat, all buttons are intact and fully operational, with little signs of wear on their faces. And it’s much the same for the condition of the heated and cooled air-suspended seat that all operators favour.

Not bad on juice

Against their contemporaries with different brand tractors of similar power and fuel tank size, the team highlights the 8S’s frugality. It’s 400-litre fuel tank is easily enough for a day-and-a-half’s work, where others need topping up by the days end.

DEF issues have been non-existent, and the cooling pack stays far cleaner mowing grass with a front/rear combination than it does baling straw, thanks to the sealed engine pod design with its air intake between the cab and engine. Our test team noted that when baling straw, chaff and debris is easily sucked up from travelling over the swath.

Bale and grain carting calls for some extensive road work too, and an on-going brake pedal sensor issue is currently affecting both this team’s 8S models. Its brain thinks independent pedal control is taking place when it’s not, and this has the effect of rapidly lowering the road speed to just 40km/hr.

A zip tie securing both pedals together is the temporary work-around, until the problem can be rectified. Operators agree that when you’re travelling at 50km/hr, the sudden speed reduction from this recurring fault is frustrating.

As regards maintenance, other than regular daily checks, greasing and filling diesel and DEF tanks, all servicing is carried out by the dealer, to the manufacturer’s intervals and required standards.

Summary

Were it not for the 8S’s spacious and quiet cab, it’s likely that our test team would have swapped colours. Despite some transmission woes that have been salvaged by a comprehensive warranty, our test team’s belief in the 8S is currently unshakeable, with the 265hp models delivering everything they want and more. That the younger Dyna-VT version hasn’t missed a beat – aside from a brake pedal sensor – has proved that the 8S is likely to remain a permanent fixture for this crew. That is, until the 6,000-hour warranty runs out.

Geoff Ashcroft

For more up-to-date farming news click here and subscribe now to profi and save.