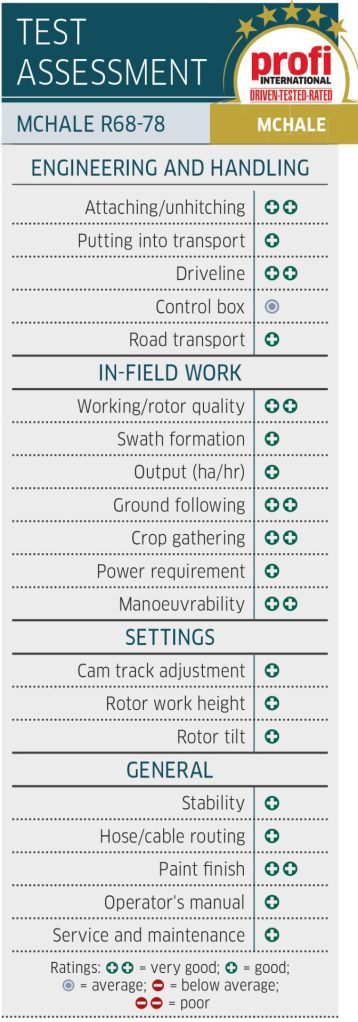

McHale launched its two-model rake range in 2017, and over the years it has been tweaked here and there to bolster reliability and performance. To find out just how capable it is, we tested the larger model, the R68-78, throughout last season.

KEEPING IT BRIEF

- The R68-78 is the larger of the two McHale two-rotor rakes.

- List price in the UK is £29,678

- It comes with a very good level of specification.

There’s a lot of choice in the two-rotor rake market, with McHale being one of your options. It has two models, the R62-72 and wider R68-78, which not by coincidence make a suitable size row for a baler as well as a forager or wagon. So that should appeal to plenty of farmers and contractors alike.

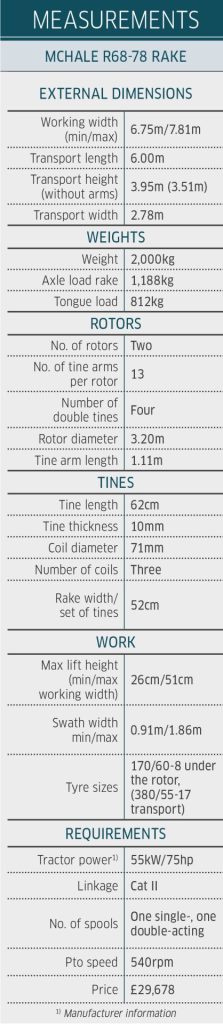

For our season-long practical test we opted for the larger of the two, which, according to the brochure stats and equally pointed out by the model name, covers a working width of 6.80m at its narrowest, out to 7.80m at its widest setting.

Likewise, hitching up to the rake is equally straightforward. The R68-78 is towed by the lower links, with a Cat II spacing; then there’s a single-acting service (for folding) with a tap for isolating, and a double-acting supply (for altering the working width), although these lack return/flow markings; and then there are the lights. The Walterscheid pto has the ribbed safety guard so there is no anti-rotation chain to connect.

There is also a rope, which when pulled, raises the mechanical stops that limit the rotor lift height at the headland and allow them to continue on up into their vertical transport position. The parking stand, too, is nicely done: pull a spring-loaded stopper and simply swing the leg into its above- horizontal position, where it is held by the pin well out of the way of any crop flowing beneath.

The last part to connect is the standard in-cab controller that allows the user to swap between independent rotor lift or both at once. This is simply plugged into a D-power plug, and there is a hook on the back of the handheld device so you can easily hang it somewhere in the cab. A toggle is flipped to one of three positions — right, both, left. Operating the spool valve then does the rotor lifting/lowering job.

While there are stowage points for all of the other connectors, there is a slot for hooking the controller on the side of the hose rack. However, it can’t be removed on a machine stored outside, the wiring going all the way from the controller to the diverter on the valve block. Compared with the rest of the R68-78, this area seems to have escaped the detailed attention of the designers. For instance, the road lights have a separate connector just behind the hose rack, so, if the wiring should become damaged, it’s just a matter of replacing the short section that runs between here and the tractor — great.

On the move

McHale fits a decent size tyre on its rakes; indeed it only uses one size — a 380/55-17 Vredestein. And continuing the nice touches, small plastic mudguards protect the LED road lights above. While there are reflective markers at the front of the rake on multi-position arms, there are no forward-facing lights at the rear. Now there may be no legal obligation for these, but, when on the move at night, some extra illumination would be beneficial on narrow roads. After all, there’s already electrical power in the vicinity.

Active steering is, of course, another standard feature. The linkage has gained some extra metal over the years, and, like the rest of the R68-78, comes across as being robust, well finished and capable of withstanding tough treatment. The rake’s paintwork looks equally good, too.

With the outer safety hoops hinged down, but all of the tine arms in place, the rake stands at 3.95m. If you want to reduce this, then you can remove and store three arms from each rotor on the rake. Arm removal is a doddle: remove the lynch pin that holds the keeper pin in place; and then just slide the arm off.

When in the rake’s transport position, the arms remain relatively upright and central on the chassis, with the inner part of the telescoping boom lowering so it sits against the frame and acts as a mechanical stop. Moreover, compared to other rakes I have used, the McHale isn’t overly wide: it measures 2.78m at its widest point, which happens to be the mudguards.

Making rows

The rotors on the bigger rake are 3.20m in diameter and have 13 tine arms. Each of these is fitted with four pairs of double tines, with a metal retainer on the end of each arm to hang onto any broken tines. We didn’t break a single 10mm tine on over 200ha. There are six (170/60-8) wheels under each rotor; the leading two feature steering and lateral oscillation. The four rear wheels are mounted on two bogey axles. All the wheels travel on fresh ground.

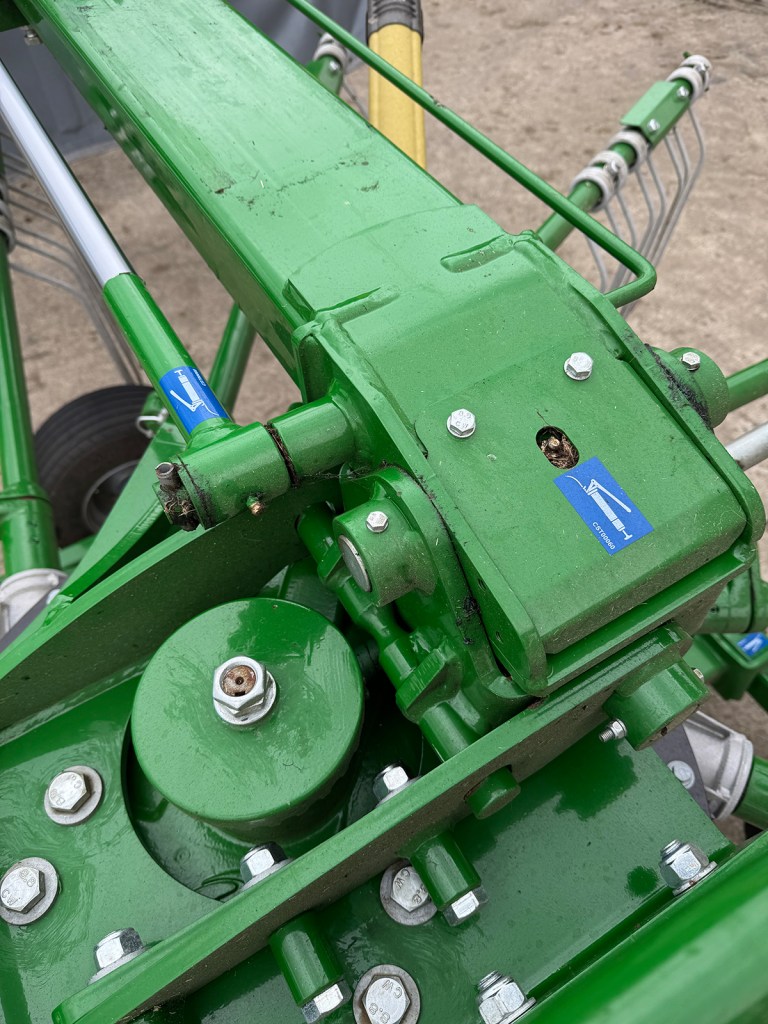

Rotor height is altered with a winder at the front of each rotor, with a good size gauge and pointer making the setting up job easier. You can also alter the cam position on both McHale rakes. Again, this is a simple affair of moving a handled pin into one of eight different holes and then replicating the same adjustment on the other side. All in all, there is enough adjustment that you can make a nice, box-shaped crop row regardless of the working width.

Working width

Speaking of working width, as alluded to earlier, this tweak is carried out hydraulically. A scale on the right-hand arm indicates the current setting, although the green marker (on a green machine) could be easier to make out if it was red. We found a width of 7.50m was the sweet spot for us to create a wide row to fill the pick-up of the forage wagon we were mostly keeping ahead of. Haylage going through a combi baler saw the working width pinched in tighter to match the baler driver’s preference for a narrower row.

Coil springs alleviate some of the weight from the rotors, which never had a problem reliably following the ground contours of our fields. The only issue we had was on a long, angled headland, where we lifted one of the rotors, but, after a bit of driving, the rotor still in work would start to rise. Tinkering with the oil flow settings on the valves did help to reduce some of this oil flowing from one side to the other.

When it came to raking corners, the R68-78 did a very good job of following the tractor. If you drive into a sharp field corner and turn relatively tight, the rake is still able to produce a reasonable curve … or at least one that sees the forage-collecting driver not spitting feathers while still mopping up all of the mown crop.

Stability also proved to be very good, not just in headland turns but also when folding for transport. To push the boundaries, we even tried folding up while parked across a reasonable slope, but the rake stayed well balanced as the rotors raised up into their vertical position.

Other details

- All of the grease points are well labelled with a blue decal. Pretty much any hinge point or sliding part is greaseable.

- The safety rails are secured with a lynch pin. This system doesn’t fit with the well thought out detail of the rest of the rake. One clip quickly disappeared.

- A central swathing curtain is part of the specification.

- The dealer price for replacement tines is £15; replacement arms are £180.

Summary

Although there has been no change to the model name, McHale’s two-rotor rakes have certainly evolved from the early days. And that constant development would appear to have paid off, as the R68-78 we tested last season was a solid bit of kit that went about its business. Yes, there are a couple of small details that could be further improved, but it could be argued that we are just being pernickety, as the rake never failed to row up light or heavy crops of silage and hay.

Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.