When it comes to mucking out cramped sheds and pens you’re generally limited to one of two options – either a compact pivot-steer or skid-steer. Whichever way you swing there’s plenty of choice out there – pretty much whatever colour you desire, it’s available. Time to meet one of the lesser-known names, Neomach.

KEEPING IT BRIEF

- The X40 is the largest of the three Nova models.

- Cost of the test model is £52,395

Visit any big ag show and if you’re not careful you can become bedazzled by the swarm of diminutively-dimensioned bend-in-the-middle machines from all corners of the planet. So, we were somewhat surprised when a few years back another name appeared in the mix. Started close to Venice in northern Italy in 2020, Neomach appears to be emerging from its embryonic post-COVID chrysalis phase into something of a competitor for the likes of Avant, MultiOne and Norcar.

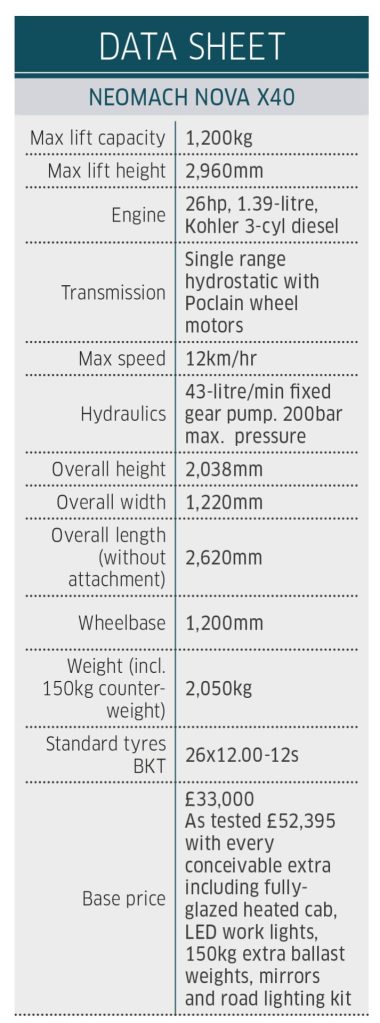

Today the firm offers three models – the Nova X20 with a 912kg rated lift capacity, the 1,080kg lift X30 and the flagship X40 which can hoist 1,290kg to just shy of 3.0m skywards. While all three vary in weight (and importantly are all legally road-towable), the two smaller machines share the same basic dimensions while the two larger variants boast similar hydraulic performance stats.

Confusingly, while the Nova trio all pack 26hp under the hood, power is provided by three different engine suppliers. Go for the X20 and you get a 1.12-litre Yanmar, the piggy-in-the-middle X30 gets a 1.26-litre Kubota and the range-topper plumps for a 1.39-litre Kohler all with corresponding levels of torque back-up.

That aside, it was the Nova X40 that we got our hands on for our brief on-farm trial. Kitted out with a fully-glazed cabin – alongside all sorts of other features you’d normally expect to see on the options list – it looks like a pretty high-spec. package for a machine of such small stature.

There’s boom suspension, a virtual ‘diff-lock’ for the hydrostatic wheel motors, multi-service hydraulic docking, ‘silent-block’ rubber cab mounts, proportional electro-hydraulic controls and a decent LED lighting package to name just a few.

Getting to work

All this sounds very impressive but how does it actually perform in the field – or shed to be more precise? To find out we presented it with the job of mucking out lambing pens in a time-weary Wiltshire barn where delicate timber uprights need to be carefully negotiated. A job normally undertaken by an aging skid-steer, we were interested to see how the Neomach would measure up to the task.

Jumping up into the cab is something of a gymnastic exercise. Set at a steep angle to accommodate the boom pivot, the rearward raked windscreen means the doorway has to mirror its crazy pitch. The result is that you have to first slide your feet into the footwell, then swing yourself into the seat hanging from the single external grab rail. (We’re told the basic stripped-back canopy version makes for much easier access). With the acrobatics out of the way, the seating position is actually remarkably comfortable. There’s plenty of legroom for even a six-footer.

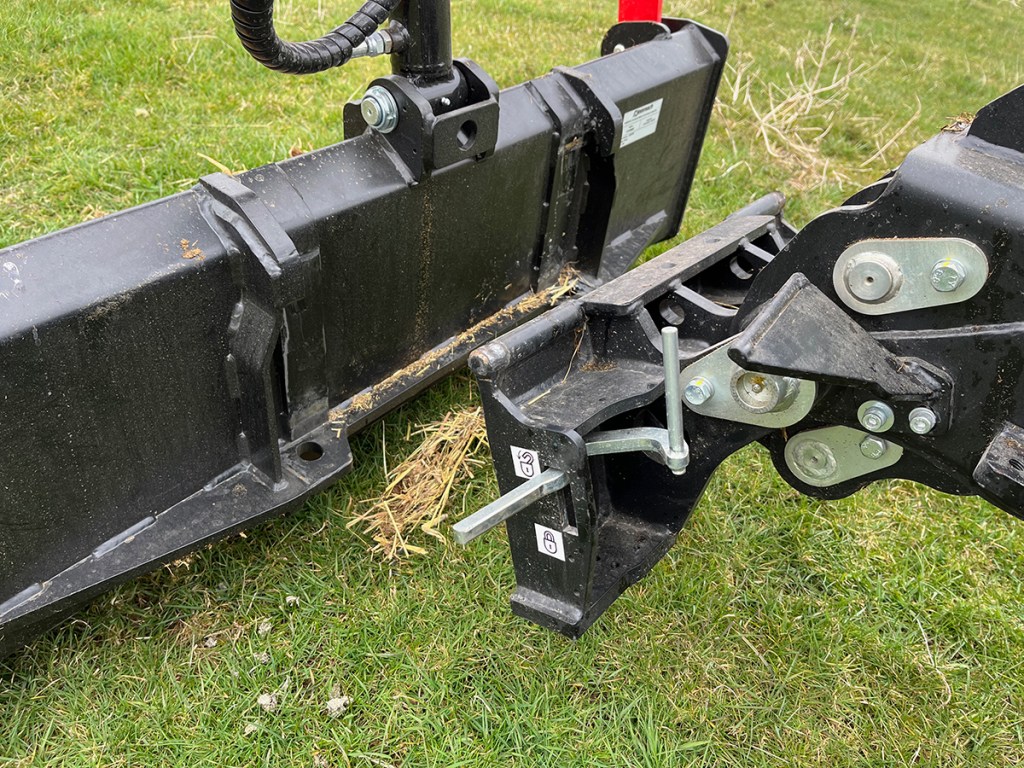

Once perched in the mechanically-sprung seat, views around the Nova are good in all directions other than forwards. Hitching on attachments requires a contortionist’s flexibility. The combination of excess boom pipework and badly placed optional headlamps necessitates a fair bit of neck stretching. The demo machine’s single-section telescopic boom is flanked by hoses for all the usual hydraulic functions in addition to three auxiliary services – we struggled to think of many attachments that require that many.

Controls are fairly standard for a machine of this type. Left and right pedals control forward and backward travel while a flimsy-feeling wand sets engine revs. Splattered with a rash of Smartie-shaped buttons, the single joystick provides electro-proportional control of all the main boom functions.

While not all the buttons appear to have a purpose, a double tap of one sets the primary auxiliary service to constant pumping while others activate the optional second and third oil supplies. Thumb sliders up on top deal with boom extend/retract and the main auxiliary supply. While proportional in their action, the combination of a single small diameter ram on our test rig’s muck grab and an exceptionally pokey pump package meant that some very delicate feathering is required to avoid a snapping turtle effect.

Hydraulic oomph

But it’s the X40’s particularly lively hydraulics that give it its trump card and Achilles heel at the same time. Ramming the grab tines into layers of well-packed strawy bedding, the tear-out force generated by curling the carriage back is quite remarkable. Likewise with lift capacity. It effortlessly hoists a heavy grab full skywards – you’ll rarely rock forwards unless you get really over ambitious.

It’s impressively stable for a machine of this size. Equipped with a total of 350kg of rear weights, it’ll comfortably lift a six-stringer end-on without nodding forwards. In this respect it’s better balanced than our host farm’s skid-steer although it lacks the out-and-out pushing power. In fact, for the job of mucking out we’d say the X40 should be able to handle a fork the full width of the machine.

All this muscularity reveals one of the Neomach’s main weaknesses. The hydraulic package is so punchy that it’ll readily pull the 26hp Kohler motor back to a stall if you’re pushing it.

Once you get used to driving it you find the sweet spot. With the engine running at 2,000-2,200rpm there’s more than enough oil-flow for both forward travel and boom functions. Like a well-trained sow on the lookout for truffles, as it comes under load the exhaust muffler starts to emit a distinctive snuffling. Pretty quickly your ear becomes trained to detect when that snout is buried too deep and is in danger of suffocation. Backing off the pedal, the 1.39-litre motor slowly comes back to life.

Loading a 10t trailer, another weakness raises its head. Despite having more than enough boom extension to reach up and over the trailer sides, the X40’s attachment carriage is unable to rotate downhill far enough to dislodge any stubborn lumps of muck. Given that it’ll crowd right back over the boom at a crazy angle, it’s an issue that should be easily resolved with a rethink of attachment bracket geometry.

When it comes to traction the X40 suffers the same issue that so many machines of this type experience. Lacking lateral oscillation at either the main steering pivot or the rear axle, if it cocks a wheel in the air at one corner it’ll grind to a halt as oil flows to the wheel motor no longer in contact with the deck.

To counter this the company has specced the hydrostatic transmission with a virtual ‘diff-lock’. When the operator senses the machine is starting to scrabble, holding down the red Smartie locks out the wheel motor relief valves effectively limiting the system’s ability to let oil flow down the route of least resistance. In this way traction is in theory delivered equally to all four corners. While competitor machines also offer this facility, the Neomach seems to do it better and in fact rarely struggled with grip in our brief trial.

The Nova has another trick up its sleeve in the driveline department. Its electronic park brake is linked to the boom controls. If you jump out of the seat without it applied both the hydraulics and transmission are automatically locked out. When you then hop back aboard the seat switch detects your presence and both drive and boom functions are automatically re-energised.

Unfortunately, the electronic handbrake itself does not automatically release when you give the machine a dose of right boot. It’ll continue to strain against the anchors until the switch is flicked.

Maintenance

When it comes to maintenance it’s obvious the Neomach design team have done their best to maximise service access. Fuel, air and hydraulic filters are all easy to get at but when it comes to engine oil it’s a different story. With the block tightly shoe-horned into a space meant for a smaller sized power-plant, here is no dipstick so you’re totally reliant on a warning light appearing on the dash should levels drop dangerously low. And when it comes to topping up things are equally awkward. To get to the filler it’s a case of removing a panel under the seat and unscrewing the mesh grille over the engine. You’ll finally get access to the cap but knowing when enough is enough is anyone’s guess.

With its super smooth underbelly, the Neomach is unlikely to get fouled up on any unseen obstacles despite its limited ground clearance. That does mean access to the sump drain requires jacking the machine up and removing a heavy steel panel.

Summary

Coming into the game as a relative newcomer, Neomach has had the benefit of being able to see what works well for the competition and what doesn’t.

It’s a high-spec mini loader in standard format with luxuries like follow-me-home lighting and USB charging points but as with any relatively new machine, the Nova X40 has a few niggles. The most irritating of which is the engineering team’s failure to work out that the attachment carriage’s geometry makes it impossible to tip into a trailer.

That should be a relatively simple issue to resolve and the Neomach seems better than other players in the pivot-steer world when it comes to traction and stability. It’s also better specced as standard for the money.

True proportional hydraulics that enable simultaneous operation of all the boom functions at once are a rarity on machines of this size. The ladybird-liveried Italian delivers in the oilflow department beyond expectations but that does highlight a deficiency in engine power – a little more poke would go a long way in matching hydraulic capabilities to power-plant performance.

We’re told that’s all in hand. While for now the Nova X40 remains the top of the firm’s teamsheet (and is due to gain a two range 20km/hr transmission), the company is apparently working on a new ‘Star’ series with greater hydraulic capacity and over double the engine power – watch this space.

Nick Fone

For more up-to-date farming news click here and subscribe now to profi and save.