New Holland’s flagship CR11 combine has been chomping through harvest for Dorset grower Peter Snell, having replaced a pair of CR10.90 models. As the end of its first full harvest draws to a close, how has the twin-rotor, 775hp beast performed?

KEEPING IT BRIEF

- Logistics and planning essential

- Straw is baled and sold

- Dealer support essential

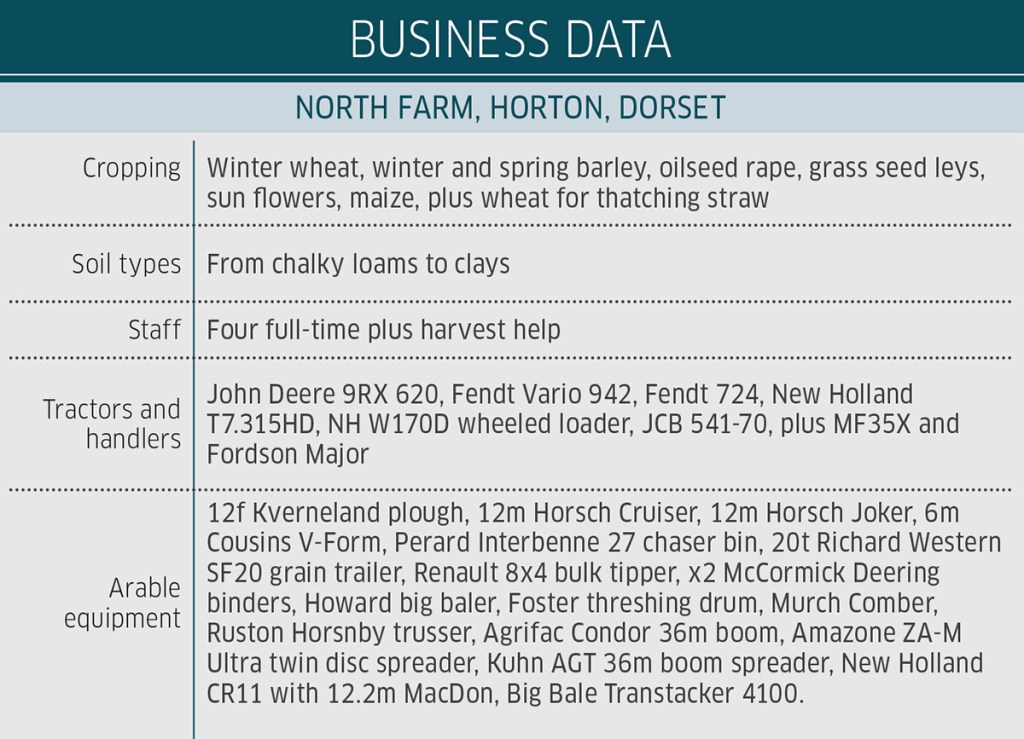

When New Holland launched its CR10.90 combine, it soon established itself as the benchmark in high-output harvesting. So much so, that Dorset farmer Peter Snell opted for two of them back in 2019 to handle a contract farming workload from his North Farm, Horton base, that was nudging 1,410 hectares (3,500 acres).

Fast-forward to 2023, and a new CR prototype was cutting its teeth on the Dorset grower’s land, benchmarking itself against the farm’s existing CR10.90’s.

“The prototype CR11 came with a much wider, MacDon FD2 header measuring 15.2m, and there’s no doubt it was a very impressive combination,” explains Peter Snell. “But we’ve spent the last eight years refining our controlled traffic farming system using 12.2m headers, so we couldn’t turn our backs on that progress, just to add another 3m of cutting width.”

With the intention of swapping a pair of six-year old CR10.90’s for one CR11, the deal was done on the ex-demo CR11, with local dealer Buglers supplying New Holland’s CR11 national demonstrator, in time for the 2024 grain harvest. It gave the Snell team some time to get to know what was to come for harvest 2025.

Sticking with the same

As the farm remained focus on its achievements in compaction reduction, the new combine deal saw the 15.2m header side-lined for the narrower 12.2m MacDon FD2 Flex Draper header, which arrived in time for the 2025 cereal harvest. While some might argue that a 12.2m cut doesn’t make the most of the CR11’s full potential, it fits in neatly with North Farm’s CTF regime, and would see the combine travel quicker than previous models.

While both the combine and its header represent a considerable investment in harvesting technology, the cost of such fire-power is being spread over a minimum period of seven years.

Operating on 36m tramlines, the farm has invested heavily in controlled traffic that centres on 12m kit. A 36m Agrifac Condor delivers high-clearance for OSR and maize, while a 36m Kuhn AGT boom-type spreader is used for solid fertilisers.

Straw is baled via Somerset contractor DN Crofts & Son, with North Farm operating its own CTF-compliant Transtacker 4100 to clear fields. Cultivations are based on one-to-two passes with either a Horsch Cruiser or Horsch Joker – both 12m – followed by a 12m Horsch Serto drill. A 6m Cousins V-Form sorts compaction, and a 12-furrow Kverneland PW plough remains on-hand if needed. Capacity and output is clearly the order of the day.

“Our cereal harvest has been effortless this year with just one combine, giving us plenty of time for stale seedbeds,” explains Peter Snell. “And while I’d like to think that it’s all been down to the arrival of our CR11, 2025 will be remembered as one of the driest seasons on record, with crops dying prematurely. And this has impacted grain quality, yields and straw volumes.”

Less juggling

He concedes that previously operating two combines brought the benefit of keeping two customers happy, in two different locations. However, juggling harvesting machinery and its associated logistics was not without its headaches and challenges, particularly with staff and additional support equipment for both grain and straw movement.

“Harvest is far simpler with one high-capacity combine, and we’ve been really pleased with the performance and capability of the CR11,” he adds.

When launched, New Holland’s flagship CR11 promised higher output, fewer losses and lower fuel consumption than previous models. Spot work rates in excess of 100t/hour was the target, while simultaneously preventing anything from slipping over the back.

To do this, the CR11 packs a 775hp FPT Cursor 16 engine and a trailer-busting 20,000 litres of clean grain storage. A high-capacity auger with the ability to spew out 210 litres/second means the CR11 can empty its load in little over 90 seconds. That alone should bring a tear to the eye of the most diligent of trailer jockeys, though the output speed can be slowed for the benefit of topping-off trailers.

No wonder then, that North Farm Horton prefers to slot a big enough target under the CR11’s extended auger. In this instance, it’s a Perard Interbenne 27 chaser bin hauled by a New Holland T7.315HD. The chaser rig stays on tramlines, adhering to the CTF regime, nipping back to the headland to unload into waiting trailers.

Inner workings

Compared to the CR10.90, the new CR11 has completely reworked threshing, separation and grain cleaning components. A 1.7m-wide intake housing brings fore/aft and horizontal tilt adjustment, ahead of a dynamic feed roller that accelerates and splits the crop flow to supply the twin rotors inside the machine.

Those twin rotors are 40mm wider and marginally longer than those used on the CR10.90, leading to an increased appetite for significantly more crop. A cleaning area twice the size sees two top sieves, two bottom sieves, and a pair of clean grain augers, the latter propel grain into that monstrous tank.

Residue management through a combined chaff and straw spreader sees debris thrown up to 18m, and being adjustable in performance lets the operator accommodate the full working width of whatever size header sits up front – even in windy conditions.

A simplified driveline means the climb in power over the CR10.90 is modest, not extreme. Installing that FPT Cursor 16 longitudinally, and at the same angle as the rotors, has resulted in fewer power losses and a simpler powertrain. Drive to the rotors also incorporates a continuously variable transmission, making drum reversal – and blockage clearing – manageable from the cab. Shaft drives and very few belts now contribute to the improved driveline efficiency.

The cab remains unchanged, but gets a pair of Intelliview 12 monitors with improved graphics, along with a host of new tech that makes operating the new flagship CR a straightforward task. NIR provides an instant protein analysis on grains.

Tooled-up

At North Farm, the CR11 can be used with a collection of headers. A 16-row 12.15m Geringhoff Rota-Disc header pulls in a 200-280ha grain maize harvest, while one of two 4.5m MacDon PW8 pick-up headers is used to collect 222ha of grass mown for seed production, and a 12.2m MacDon FD2 Flex Draper equipped with duck’s foot paddles on the split reel, takes care of everything else, including a 20ha sunflower crop.

A Shelbourne Reynolds stripper header continues to occupy barn space, but it is unlikely to ever find its way onto the front of the CR11.

North Farm Horton’s 1,416ha peak workload has eased back slightly in recent times, but the agri-business is still collectively farming over 1,295ha. In addition to the 283ha farmed at North Farm, Peter Snell and his team look after ground for six customers, and there’s always an element of ad-hoc combining each year, as neighbouring farms help each other out when faced with breakdowns and tightening weather windows.

Across the business are four locations for storage and two weighbridges, creating full transparency and traceability for everything grown.

Mixed cropping

Cropping includes winter and spring barley, grass for seed production, oilseed rape, winter wheat for feed and milling contracts, organic Lucerne for seed production, sun flowers and grain maize. Everything goes through the combine.

Peter says that all but grass grown for seed production, is handled effortlessly. In this instance, four varieties of grass are used for seed production to deliver basic and C1 classifications for merchants. For this task alone, two combines are called upon.

“The CR11 could probably handle this workload entirely, but we’d need a change of header,” he says. “The short-term answer is to hire a second combine through our local New Holland dealer Buglers, as we already have two MacDon PW8 headers from running the two CR10.90’s.”

“Each header can pick up two mown rows of grass from our front/rear 6.0m plain disc combination, and we could probably collect four rows with the CR11 if we were to swap our two PW8’s for one wider header,” he says. “We now have the cleaning capacity and sample quality, along with lower losses.”

“And with far larger sieve areas than the old CR10.90, the new CR11 is really good with grass seed,” he adds. “We can combine grass at 20% moisture content but with the capacity we have, waiting for 15-16% is now far less risky.”

The many different contract farming agreements on the table provides different challenges when it comes to logistics. Not all farms are ideally suited to the CR11, and across the area farmed, field sizes range from five acres up to 150 acres.

Logistics – size and costs

“The average field size is around 40-45 acres,” explains Peter. “There’s greater challenges ahead with some on-farm storage facilities that we encounter, and that can mean using 12-tonne trailers – anything larger means no access for tipping.”

The advantage of one big harvester means attention has been given to boosting logistics, finding yet even more efficiency, over and above the CR11’s headline stats. And it’s a point not lost on Peter Snell and his team, so the combine can continue to rattle through crops with ease.

Away from the constraints of smaller sheds, the North Farm crew have been trialling a low-cost alternative to tractors and trailers, with the arrival of a 20-tonne capacity eight-wheel, bulk tipper lorry.

“I paid £15,000 for our 2016 Renault tipper lorry last year, and it handles the same payload as our £350,000 tractor-trailer combination which uses a 20-tonne Richard Western trailer and Fendt 942 Vario,” he says. “It’s quite an eye-opener when you focus on the cost-per tonne moved. That said, the farm needs a 400hp tractor for cultivations and drilling, and because of that, we can use it for other jobs, even if it is just grain haulage.”

Running a lorry is far from straightforward, and such dedicated haulage has its own specific requirements. These include regular maintenance inspections, an O-licence, and a driver or two, who hold a category C entitlement for LGVs.

“Then there’s tachographs, and driver’s hours to follow,” he says. “But it’s a cost-effective option compared to our tractor and trailer. We’ve got both extremes in play, and it’s been an interesting exercise to put under the spotlight. It could lead to a second lorry for 2026.”

Behind the wheel

Combine operator Tom Hull has yet to push the CR11 hard, and says what he’s experienced this year has been very impressive.

“In our experience this year, the CR11 has proved itself to be equivalent to one-and-a-half CR10.90’s,” says Tom. “I’d expect that gap to widen, particularly in heavier crops, where the differences would be far greater.”

He says that in wheat, 85-95 tonnes/hour has been a comfortable and regular achievement at a forward speed of around 8.0km/h, and with very low losses.

“Yields have been lower, and straw volumes much lighter than usual, but typically, there have been less than five grains under the palm of my hand when checking what’s gone over the back,” he adds. “The parameters are so easily adjustable from the cab, that we can make easy decisions in those areas where compromise may be needed.”

He says that the FD2 header carries many improvements over the FD1 previously used at North Farm.

“Wheels behind the header are far better, and they can comfortably remove weight from the skids when needed,” says Tom. “We did have steel skids underneath, and that’s a recipe for trouble with flints. We’ve since swapped to stainless steel skids and the risk of sparks has been eliminated.”

“The FD2’s draper belt is deeper, so it flows far better in heavy crops, and we’ve also got a sunflower kit too, with much deeper pans in front of the knife to catch seeds, as header losses with sunflowers can be substantial.”

Tom says that duck foot paddles on the header reel have been beneficial with easing the crop onto the FD2’s belt ‘heads first’, and the only thing he’d change about the header would be to go wider still.

“I’d really like the triple reel, but it’s only available on 45 and 50ft headers and we’re too heavily immersed in our 12m CTF system,” he says. “Being on a CTF regime, and having that bit extra with the FD241 means there’s now a bit of tolerance on either side of the header to stay comfortably on target with our 36m tramline system.”

“I’m already looking forward to the 2026 harvest, and a bumper crop would be the best way to see just how much more performance we can gain from the CR11,” says Tom. “Though it could be an altogether different scenario in a wet year.”

Summary

Given the rising cost of equipment, changing two CR10.90 combines for two replacement models proved financially prohibitive for this Dorset farming business. The switch to one larger model though, appears to have made the most of resources – both financially and operationally – to improve harvesting efficiency on a cost/tonne basis. Doing so has put greater reliance on its relationship with the local dealer, to keep tracks turning in the event of a breakdown.

Geoff Ashcroft

For more up-to-date farming news click here and subscribe now to profi and save.