WORKSHOP: Replacing components on printed circuit boards: Carefully does it. When it goes really bad, a defective part on a circuit board can ‘down’ a whole machine. Although replacing the culprit — perhaps just a button — would only cost a couple of quid, the dealer technician will more than likely replace the entire circuit board … along with submitting you a much larger invoice.

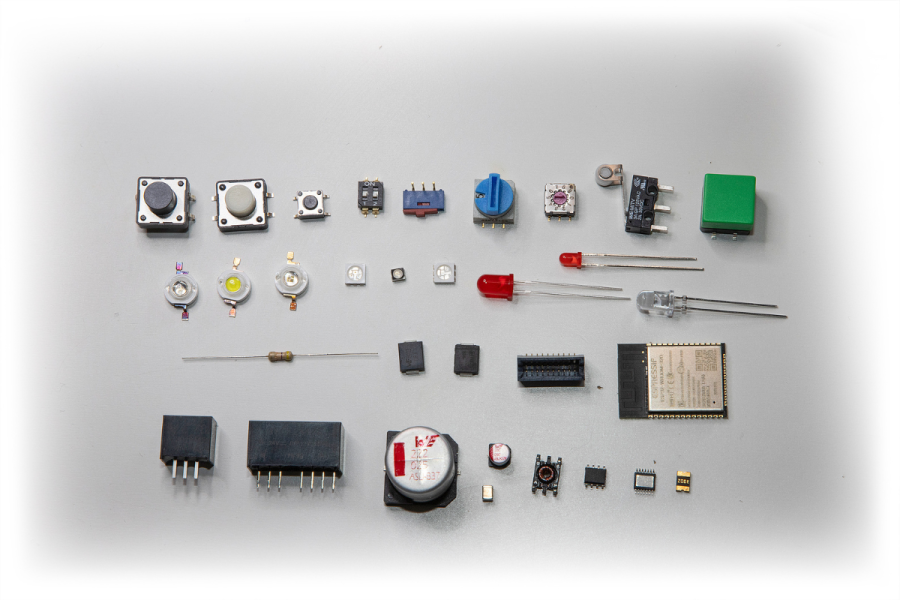

With some basic knowledge and practice, you too can replace many of the essential components on a circuit board. We learned from computer scientist, teacher and developer of ISObus control systems Franz Höpfinger, from Schwindegg in Bavaria, a few tricks that will enable each of us to carry out minor circuit board repairs. He also tells us which tools are the main ones to have. A circuit board, also known as a PCB (printed circuit board), basically replaces the wiring of electrical components. Its core consists of a GRP plate (glass fibre reinforced plastic). Both sides of this plate are coated with a conductive layer of copper. Next, the board is divided into separate areas, which are shielded from each other. This, for example, can be done with a chemical etching process. Then round or slotted holes etc. are added for attaching certain components or for using as attachment holes. As a last step, the board is coated with an insulating layer of varnish.

For more up-to-date farming news click here and subscribe now to profi and save.