In its range of mulchers, Samasz has the Mamut series, including a triple flail set-up that’s capable of shredding large amounts of organic matter … as we found out.

KEEPING IT BRIEF

- The rear 860 mulcher can be stored folded on four legs or unfolded.

- Samasz plans to offer these items in its green and black livery instead of the standard municipal orange.

- As well as your regular mulched crops, Samasz says Mamut can handle material up to 80mm thick.

Samasz manufactures a wide range of flail mulchers in various designs and working widths. Its top-of-the-range product offering is the Mamut, which it classes as “super-heavy-duty” machines. The line-up includes three front-mounted models (2.50m, 2.80m and 3.00m wide).

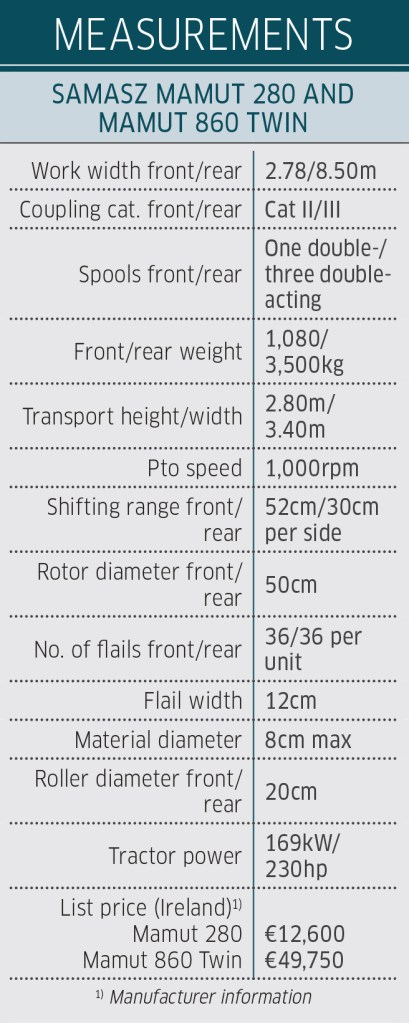

By combining a rear-mounted butterfly fold model (available in working widths of up to 8.60m) with a 2.80m front-mounted unit you can still travel on the road while achieving an overall working width of 8.50m with a sufficient overlap.

Straightforward front mulcher

Our test combo was just this. On the front we had the Mamut 280, which has a mowing width of just under 2.80m and a transport width of less than 3.00m. This model has a double Cat II headstock so it can be front- or rear-mounted.

It also has a hydraulic side-shift, with the headstock sliding on a couple of chromed shafts with a total movement range of 52cm. This does require a double-acting spool.

We particularly liked the smooth outer hood of the mulcher. Although debris does still accumulate on the surface, it is easy to blow or wash off.

Generally, there are just a couple of spots which take a bit more effort to clean. One area that takes more cleaning effort is the area between the gearbox and its protective cover, where material can gather and bake on — this is where we spotted blemishes in the paintwork at the end of the season.

Power under strain

Tractor power is supplied by the 1,000rpm pto shaft to a right-angle gearbox with over-run slip clutch. We mainly used the Mamut on a John Deere 6215R with 600/70 R28 front tyres and found that the Bondioli & Pavesi shaft was running at a steep angle, to the point the universal joints were at their limit. Since the 6215R is typical of the size of tractor for this type of work, we think the angle of dangle needs improving, otherwise UJ service life will be short.

The right-angle box sends the power to five V-belts on the left. A spring-loaded tensioner maintains correct belt tension, which can be checked through a small aperture.

Skids set the height

The rotor shaft is just over 20cm in diameter and carries 36 flails, each with a cutting width of 12cm so there is ample overlap. The working height is set using skids with three hole settings and on the rear roller, which has four positions to choose from.

The housing is lined with a welded wear insert and a bolt-on counter blade made up of six replaceable sections. According to Samasz, this uses wear-resistant steel. At the front, a curtain of hard plastic fingers helps to reduce the risk of stones and crop residue being ejected.

Sturdy rear wings

The rear Mamut consists of a pair of flails, each with a working width of 2.97m. With our 280 on the front, we pushed the rear units all the way out on their side shift and measured an overall work width of 8.50m with an overlap of nearly 30cm. If you need more overlap or want a narrower working width, each rear unit can be pulled in by up to 30cm using the hydraulic offset.

The arms that support each of the rear flails look sizeably well-built. Each unit has two cylinders that take care of lifting, hydraulic suspension and lifting at the headland. The central pivot above each mower provides ± 5° of contouring, which worked well for us. The total up/down travel range is 20cm.

To help you get the tractor’s lift arm height correct, there is a useful marker aid that you just line up. For transport, you should lower the tractor linkage slightly, but there is still sufficient ground clearance, or at least that was our experience. Individual suspension comes from an accumulator on each wing.

Hydraulic system with room for refinement

The tractors spools are used to operate all of the Mamut’s hydraulic functions. Three double-acting spools are required: one each for folding/headland position, work width and suspension pressure. There’s no need to switch between the various functions, thanks to a clever, Samasz-designed control system.

That said, the Mamut operator must follow a specific sequence. For example, unfolding entails: set spool one pumping to open the transport lock and extend the arms, then spool two to lower the wings at full working width. This is followed by spool three into float to set the work position before setting spool two over to pump to adjust the ground pressure depending on ground conditions.

Thankfully, Samasz supplies a quick-start guide, but the control system is pencilled in for significant simplification in the future. On a more positive note, all the hoses have well-designed, easy-to-grip handles.

On our machine, the hydraulic valve block was incorrectly set at the factory, and we couldn’t even operate the Mamut 860. The service techs from Samasz were quickly on hand to get this sorted.

Driveline mishaps

The rear unit also uses Bondioli & Pavesi driveshafts, with power initially flowing to a central gearbox with an over-run slip clutch, which then splits the drive and sends it to the intermediate gearboxes on the wings. From here, power flows to the pulleys, which, in turn, drive five belts. It is pretty much the same layout as on the Mamut 280.

On our test machine, the bearing on the left pulley was faulty, which caused the pulley to run out of true and also damaged the housing. Clearly, these things can happen, though frustratingly Samasz didn’t have the replacement parts on the shelf at the factory or in dealer stock in mid-season, so we had to park up and wait. It was a similar story with replacement belts as well as the rotor bearings and the rotor shaft itself, which showed premature wear.

However, Samasz pulled one out of the bag, so to speak, by sending out a replacement machine. Parts supply and technical support have since been given a boost with a new subsidiary, Samasz Deutschland. This set-up opened in late 2024.

Short, small and even

As with the front machine, the hood on the rear units has a wear liner complete with counter blade. Unlike the wear liner on the front mulcher, this is bolted in place, which should make its replacement a much swifter operation. The counter blade consists of several bolted elements. A second counter blade is available as an option. Each of the rear mowers was carrying 36 flails.

The performance was mixed but mostly positive. Across all of the crops we tackled, material was evenly cut and well shredded or split open to aid breaking down with even distribution across the full working width. Another strong point is the Mamut’s suction effect. This allows it to lift material that was lying on the ground or had been driven over a little better than we have found on other machines. However, this improved cutting performance comes at a power sapping cost. For example, in wet maize stubble, forward speed dropped to 3.5–4.0km/hr at times.

In a side-by-side flail comparison against another mulcher (with an almost identical tractor), the Samasz was slower but gave a noticeably finer cut. This should encourage material to decompose quicker.

The working height is adjusted the same as on the front unit, by adjusting the skids and the roller. You can also choose to deposit material in front of or behind the roller. Making this change does involve a bit of spanner work, though.

Summary

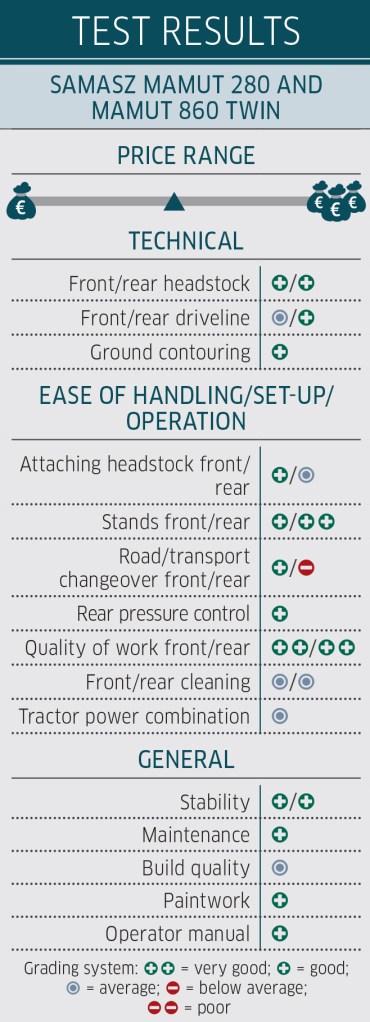

With the Mamut, Samasz has put together a mulcher combination that is pitched at more demanding users. The quality of work is first rate although this does come with a demand for power. Each rotor carries 36 flails. The machines are relatively straightforward, but operators need to be familiar with the quirks of the hydraulic system by reading the user manual.

With list prices of roughly €12,600 for the Mamut 280 and €49,750 in Ireland from Egmont Argi for the Mamut 860, this Samasz combination offers an attractive package in the heavy-duty mulcher sector.

Christian Brüse

For more up-to-date farming news click here and subscribe now to profi and save.