Samasz is starting to roll out its next generation of mowers, and part of that refreshed range includes the XDF301 SH front- and KDD911 STH rear-mounted combination. But it’s not just a fresh face … ISObus controls are also part of the revamp.

KEEPING IT BRIEF

- The XDF301 SH front mower is brand new, while the KDD911 STH rear mower has been revamped and made ISObus-compatible.

- With the new combination, Samasz wants to up its appeal to contractors.

- The price of the combination is lower than many of its competitors, which adds to its appeal.

It is not just the colour scheme that has changed on Samasz mowers; it has also introduced some new models. And we managed to get our hands on one of the firm’s new generation of triples.

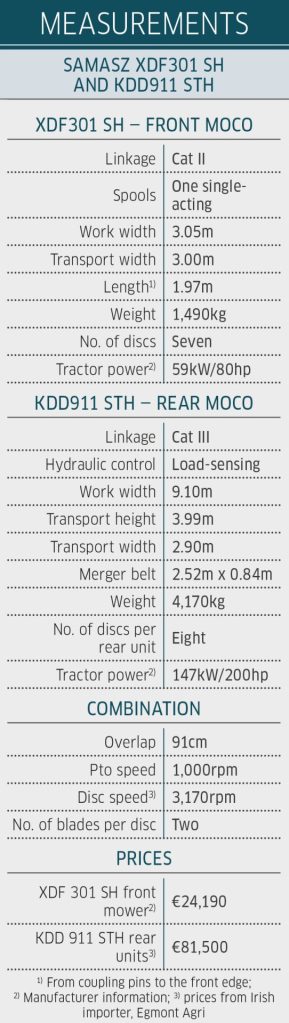

So, what did we use throughout last season? A pre-production version of the new 3.0m cut XDF301 SH partnered with a 9.10m wide KDD911 STH ISObus — which, as the name suggests, is now ISObus-compatible.

Not direct

Even with its new front mower, Samasz has decided to stick with an A-frame rather than hitching directly. The beefy pto shaft is from Bondioli & Pavesi, and this only needs to be secured with a chain at the mower end. Then there is just the sensor cable and another for the optional side-facing camera system.The latter lists at €1,800 but has been tested by the DLG, so it is fully compatible for use on German roads.

Last item to connect up is the single-acting hydraulic hose, which looks after the SH’s headland lift-out and the suspension. The pressure in the suspension system is set on the ISObus screen and can be checked on a pressure gauge.

Pull-type configuration

For the XDF, Samasz uses a pull-type layout. The stylish looking frame boasts a centrally mounted support arm that the mower is suspended from, while under the plastic cover is the hydraulic suspension along with the rams for headland lift/lower.

To ensure the correct hitch height, Samasz has come up with a helpful solution using sensors and linking the hydraulics with the rear mower’s ISObus controls. A green dot appears on the display when the linkage is at the ideal height, permitting the mower to exploit its entire up/down range of travel. Samasz claims 55cm up and 33cm down movement and a lateral oscillation of +/-22°. Throughout our test, the travel range proved to be more than sufficient

As mentioned, the mower is carried on one arm and is guided by two extra links. The weld between one link and the ball joint broke, which then caused the remote grease lines to be ripped off. Not so good, but what is good is that Samasz groups all the front-mounted mower’s grease points into lube banks — excellent.

Seven discs cut 3.05 metres

We measured the actual cutting width of the seven-disc bed in the field as 3.05m. Swath- forming doors are standard, though you do need tools for adjusting their length. But the angle, for setting the row width, is done by adjusting screws with a grippy handle.

The conditioner uses V-type steel tines and a chequered steel baffle plate. There are two speeds as standard (700 and 1,000rpm) which are selected by moving a handle on the left-hand side. The lever that sets the baffle plate has seven working positions and is located over on the right. For Intensive crop conditioning we opted for selecting a speed of 1,000rpm and a middle position with visually good results.

Limited cutting heights

We’re already pretty familiar with the quiet running PerfectCut bed. It is of a welded construction and, according to Samasz, is made of special steel. It has relatively wide skids; high-cut skids are available for €550. Each disc has individual overload protection which it calls ‘safeGear’.

The quality of cut was fine for us, though we found the cutting height adjustment a bit limited. Samasz reckons the cutting heights range between about 4.5cm and 7.0cm, but we measured 8.0cm to 10cm; longer stubble is not possible if that’s what you’re after.

There are mixed opinions on the end curtains which have good and bad points: they fold hydraulically and the hinges are connected to the grease lines — great. However, metal top panels will bend if you hit something — there are no protective tubes as on some competitors or even better again made from plastic which can absorb thumps and bumps much more readily.

Rear mower with ISObus

The KDD911 STH rear mower comes with integrated merger belts and has the same steel conditioner set-up as the front mower.

To get going, the mower attaches using Cat. III couplers. Then connect the load-sensing hydraulics (with easy-to-grip couplers) and lastly the data and electric cables. The beefy headstock is a solidly constructed piece of engineering, yet it still offers easy access to work around it.

When in the hydraulically locked transport position, the ground clearance under the gearbox is still 30cm and the overall height 3.99m. Each folded mower frame rests up against a pocket in transport, making road travel very quiet and snug.

The arms are suspended hydraulically, with the pressure preselected on the terminal. Impact damage protection is also achieved hydraulically on both mowers: in the event of a collision, the units pivot backward and upwards by 35cm. Good.

The cutting height is adjusted on the top link. Again, the maximum cutting height is not much more than 8-10cm without high-cut skids (€1,250 for a set on the KDD). The lift- out height was always plenty enough for us.

Cutting narrow curves is possible

Overall cutting width at the rear measured 9.10m. These are eight-disc cutterbars on the back units. Like the front, each disc has two blades and we were very happy with the cutting quality.

Samasz attaches great importance to the fact that each rear mower has an extra disc sited on the inside of its cutterbar. This is to maximise the overlap with the front mower and eliminate strips being left on slopes or in curves.

Our team measured a clear width of 2.14m in between the inner blades on the rear mowers, so the overlap per side is just over 45cm, and we were able to make significantly tighter turns than usual without the worry of leaving any unmown grass.

Solid conditioner costs power

The conditioner has a bottom plate that is designed to minimise losses, especially in leafy crops or wholecrop silage. However, this enclosed system also saps power when the forage is wet, so we removed the plates once the wholecrop was cut.

The merger belts are hydraulically driven with infinitely variable speed control. We had to replace one oil motor that stopped working during the test. We did operate the triples on different tractors, and on all of them we noticed that the belt speed would drop briefly when another hydraulic function is activated — something that Samasz should address. On our test machine, the only way to adjust the width of the row created by the merger was to make manual alterations; there is now a hydraulic option (€3,100).

When the grouper isn’t needed, the belts can be hydraulically raised out of the way with a tap on the ISObus terminal. Unfortunately, the mergers can only be raised one after the other and not simultaneously — Samasz says it plans to change this in the software.

When folding up the KDD for transport, the rams for the mergers occasionally lost their pressure. When this happened, they couldn’t be secured and would start fouling each other. Samasz has corrected this issue since our test.

ISObus operation

The KDD 911 STH hardware has been on the market for several years, but it has now been given brand new ISObus controls. The display layout is well executed and the menu structure is easy to understand. Adjustments such as to belt speed or ground pressure are quick and straightforward to make.

However, many of the fine adjustments were not yet right on the test machine. Especially when using the tractor’s function keys, there were repeated delays or even half-executed responses. Samasz says this was a software problem that has since been identified and is being resolved. At first we thought the tractor was at fault, but the issue popped up with other tractors and brands as well. When operating the same functions via the touch screen, we didn’t have the response issue and everything worked just fine.

Another issue was that the mower would occasionally fail to fold up in auto mode. This was down to the position of the sensors, which were damaged during work and would then signal error messages. Samasz wants to change the position of these sensors on future machines.

It will come as no surprise to learn these software and sensor issues did become very annoying, but Samasz took the trouble to visit the test mower several times during the season. The engineers looked into the errors to understand the various issues and are working to correct them.

Summary

Samasz has brought the KDD911 STH into the ISObus age and integrated the all-new XDF301 SH front mower into the control system, creating a potentially powerful combi on a not too light tractor.

The software still has teething problems, especially when operating the combination from an ISObus-capable tractor with the F buttons. Samasz is working hard to fix these issues.

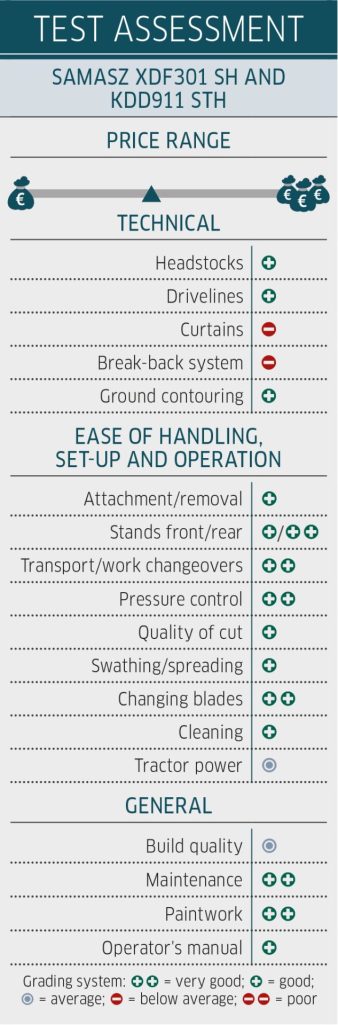

The hardware of both mowers is impressive. The cutting quality is good, the mowers are easy to maintain and comparatively easy to wash. The list price is also eyebrow-raising at just under €105,690, yet these triples still cost around 15% to 20% less than others.

Christian Brüse

For more up-to-date farming news click here and subscribe now to profi and save.