Schäffer has introduced its third generation of 9640T telescopic wheeled

loader with the biggest differences found in the more driver-focused cab.

KEEPING IT BRIEF

- New cab was shown at Agritechnica in 2023 initially for the 8620 T-3. It has now been fitted to the third generation of 9640.

- A new display, auto-functions and assistance systems have been added.

- On-board weighing will soon appear on the options list.

- The biggest Schäffer telescopic loader, the 5.3t lift, 177hp, 9660 T-2, is to get the same updates.

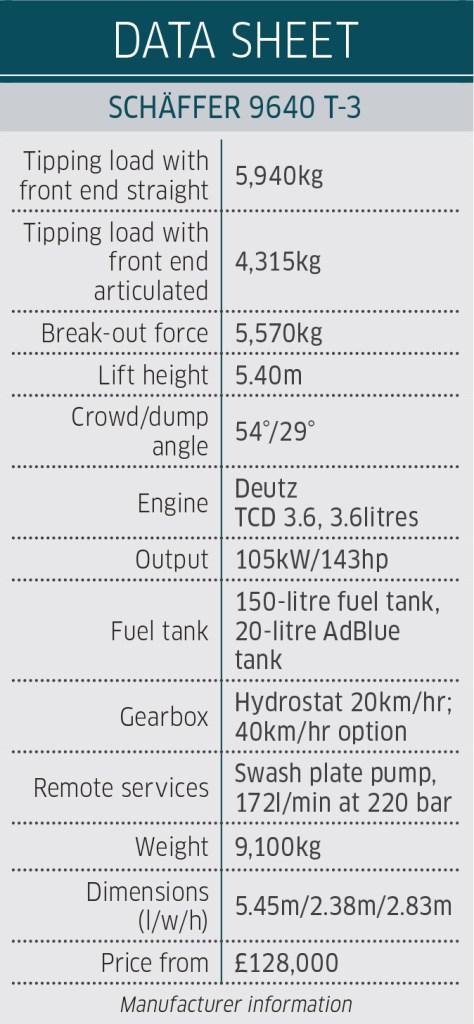

Since February, telescopic wheeled loaders have had to comply with DIN EN747-3, the same regulation that was introduced several years ago to rigid-chassis machines. In short, they now require fully integrated overload protection. While making this change, Schäffer grabbed the chance to give its 5.40m, 4.30t lift 9640 a freshen-up with a new cab.

Office change

Once in the seat, the first thing that really stands out on the new cab is that there is now a sweeping side console on the right-hand side. This does mean there is no longer a right-hand door; however, there is still a large window that can be swung back 180⁰ and pinned open.

The top of the cab frame is no longer as rounded, and the new flatter top has really benefitted headroom, especially when the user is getting on and off the machine. The cab is also 10cm wider than on the old T-2; in fact, the cab space has increased by 20%. The only downside is that there is now an overhead crossbeam in your line of sight when looking up.

Speaking of the view, Schäffer offers up to three optional cameras. As well as basic front- and rear-view cameras you can opt for a second rear-facing camera with AI-operated person detection (€2,140). With this technology, the person is outlined by a red frame on the screen, and there is an audible warning sound. The camera images are shown on the new 10in display on the side console.

Fresh layout

Schäffer developed the screen’s interface inhouse. In addition to the usual icons for things like the transmission mode and fuel level, there’s a large pictogram of the loader. Tapping on one of the seven icons will bring up a menu showing the various setting and display options — a clear, easy-to-understand solution.

For example, the loader operator can quickly adjust boom damping, either permanently or automatically, for three freely selectable speeds. You can even individually select the end of stroke cushioning for each cylinder. It is also possible to adjust the hydraulic responsiveness of the joystick to one of three levels. Another handy new feature is the ability to the change the direction of the third service rocker switch if you have connected the couplers the wrong way.

All of the functions can be accessed with a single tap on the touch screen. Only the lights and windscreen wipers are operated from buttons in the roof on the right-hand side.

Another big plus on the cab ergonomics is that the handbrake has been repositioned from behind the seat to a far more logical location beside the steering column. The steering wheel adjustment is now altered by a pedal — very good. And to make it easier to clean the floor, the pedals are now suspended.

New joystick

Continuing the user comfort theme, the redesigned joystick is mounted on the seat so that it moves with it. The joystick also operates solely using electrics through the handler’s CANBus system. On the top of the stick, there are three buttons that can be individually programmed — for example, for operating the hydraulic service at the rear of the 9640 for tipping a trailer.

Then there are all the assistance features, which can be enabled from a button on the underside of the joystick next to the bucket shake button. These assistance features include ‘return to dig’, which will move the boom and attachment to the preset lower or upper position when the user presses the button and moves the joystick accordingly. Thanks to the integrated telescopic function this is a handy feature when you are doing repetitive loading cycles.

Another feature is the position assistant, which maintains the current position of the attachment as it moves through the lift arc (angle/distance relative to the machine).

The third of these auto functions is the tool assistant. With the push of a button and knocking the joystick across to the right, the handler can tip the attachment, including the shake function, and activate the third service. All excellent stuff.

You can’t set up profiles for the implements, at least not yet, although this is something Schäffer is working on. We think this would make the auto functions that much more user friendly, as would the ability to save operator profiles. Currently, only the most recent saved settings remain active.

The boom

Schäffer hasn’t made any changes to the 9640’s chassis, boom or driveline. It’s still the same 9.0t or so machine with a maximum lift height of 5.40m (to the pivot pin). For comparison, it could line up with the likes of JCB’s TM320S.

A quick word on the integrated overload protection, which is almost superfluous to the rest of the updates. When the shovel is overloaded and the boom cut-out activates, if the operator presses the override button, the boom is automatically retracted in order to bring the centre of gravity closer and allow the 9640 to regain its balance.

Price and improved comfort

Schäffer is asking about £145,000 for the 9640 T-3 as tested – roughly 5% more than the previous model. While ticking the box for the overload protection is nice, it is the massively updated cab that operators will appreciate much more.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.