The test candidates differ not only in their design but also in how they handle. Read on to find out why there are no winners or losers in this comparison.

KEEPING IT BRIEF

- A maize kit is not necessarily advantageous.

- In terms of overview and handling, there were bigger differences than expected

- Fork weight has a noticeable impact on handling.

When things get hectic on the clamp, you need reliable tools that make your life easier, not harder. And having a fork that you can easily fold to get closer to the wall when rolling, or has the ability to carry loose, short material, can make the difference of quickly clearing forage and creating a neat- sided, level clamp.

Visibility

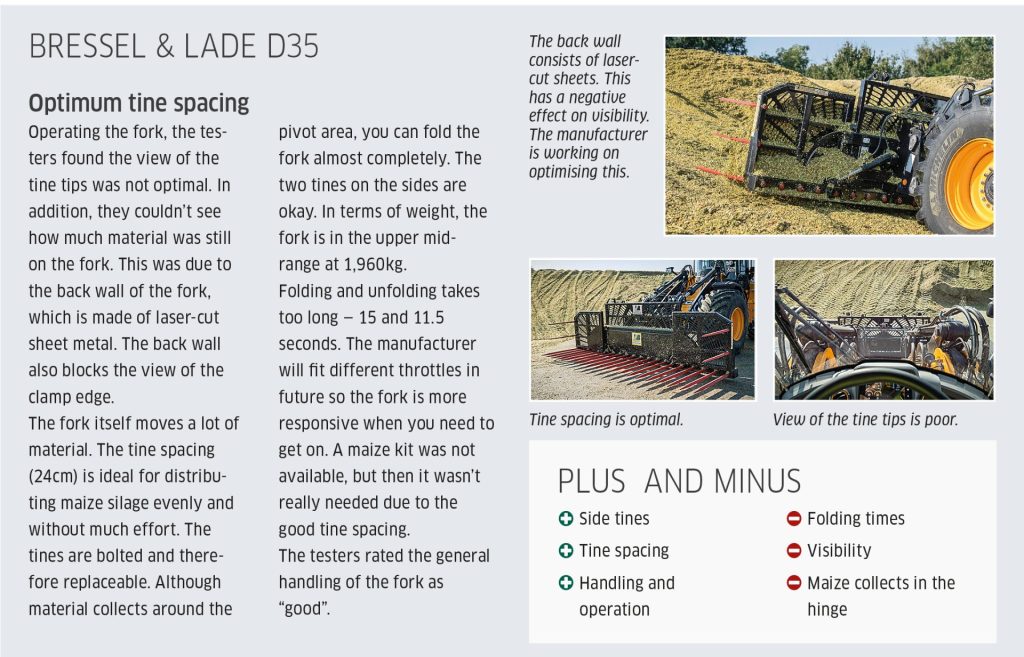

The back of the fork determines the view of the fork tines and the clamp edge. Visibility on the Fliegl, JCB and Kock & Sohn was particularly good while okay on the Saphir and the ProDig and VDW. With the Bressel & Lade, you can only see the tines if you lean off the seat, as the rear of the rake is made from cut-out sheet metal; in fact, visibility was an issue on this fork for the test team, as you only have a mediocre view of the clamp edge.

Maize kit

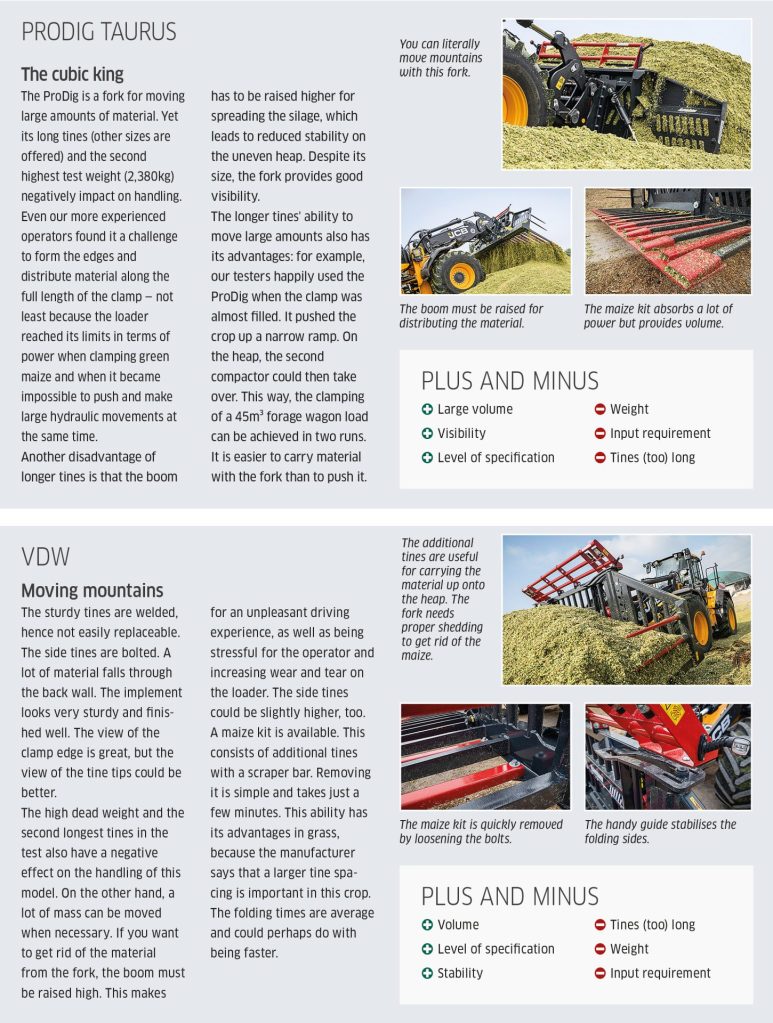

When we were organising the forks for this test, we also asked for them to come with a maize kit where possible. This kit tends to include removable additional tines and a scraper bar to reduce the tine spacing and minimise losses in maize, whereas in grass you can increase the tine spacing again. This option is offered by Fliegl (£1,355), ProDig (£1,065) and VDW (£1,677).

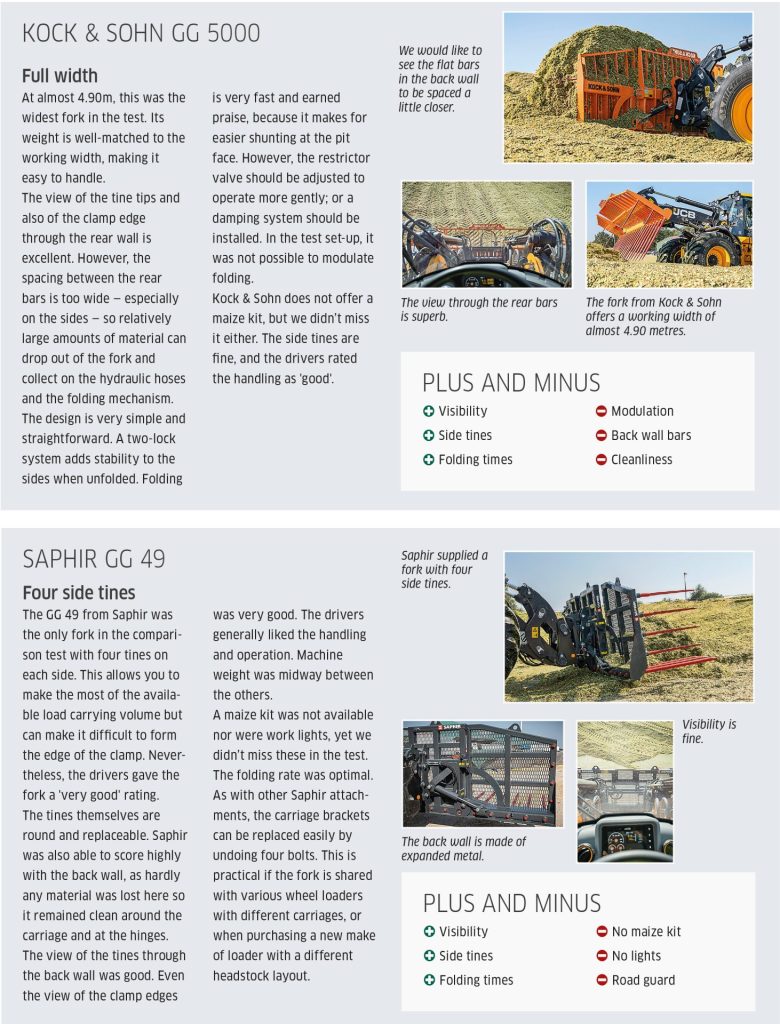

Our operators pointed out that the maize kit wasn’t always beneficial, as too close a tine spacing can require more flicking to evenly distribute the material. We consider a tine spacing of 24cm to be the optimal — as is the case with Bressel & Lade and JCB. However, this close a tine spacing is probably not so good in grass.

The scraper bar slows down the material during dumping, which also requires more work with the loader. In addition, our test impression was that the scraper bars absorb some pushing power, which in turn could have a negative effect on fuel consumption.

Short and long

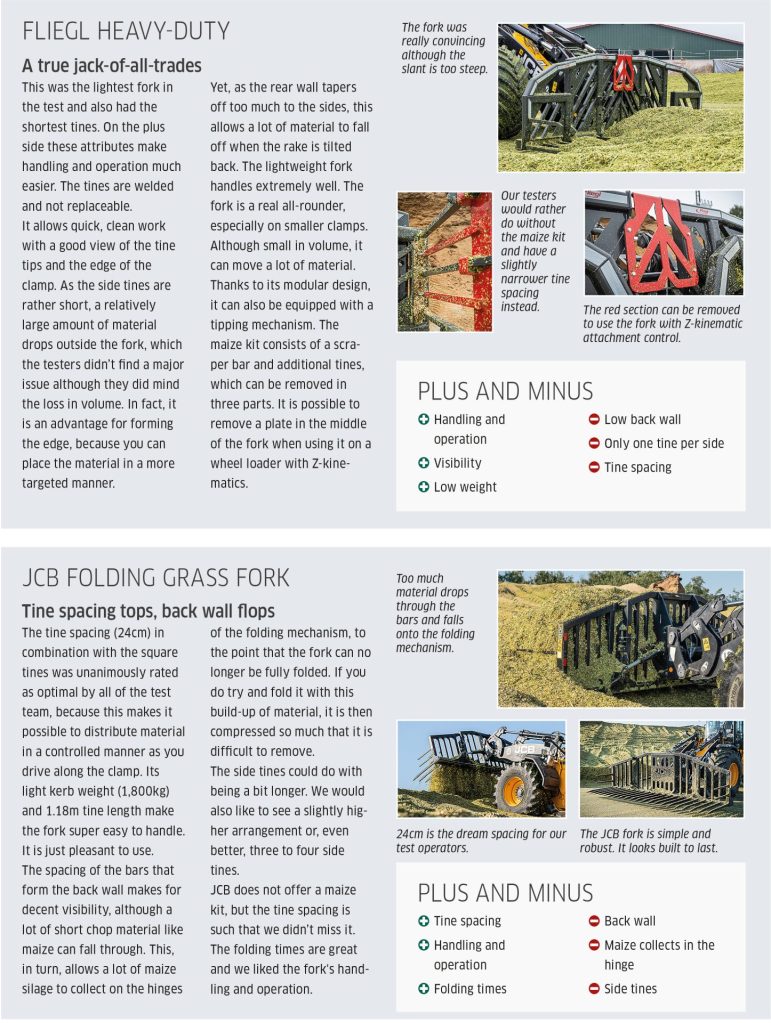

Overall tine length has a major influence on handling. There were big differences here between the seven: the longest tines on the ProDig are 1.60m long and almost 60cm longer than the Fliegl tines, which measure about 1.0m.

Whether short or long tines are better will depend on the type of forage and loader operator. Our test drivers all agreed that shorter tines offer more flexibility and yet handle large masses of material. Forks with short tines are therefore versatile, even on small clamps.

Long tines are better suited for moving large volumes of material very quickly. On our biogas clamp, the long tines came into their own towards the end, when the second compacting tractor took over the finishing work up on the heap and the loading shovel had to quickly move the maize up. Long tines make it easy to carry the material up instead of pushing it. Incidentally, the shape of the tines had no noticeable impact on the work.

Side tines and weight

The number of tines on the sides varies from one (Fliegl) to four (Saphir). When working, it is noticeable that more material is lost at the side on the models with fewer side tines, but this isn’t a problem. It can even be an advantage when shaping the edge, because maize can be placed precisely along the edge.

The lightest fork was supplied by Fliegl (1,560kg); the heaviest one was the ProDig (2,600kg), closely followed by the VDW at 2,540kg (tested unit without guard).

Even though one might assume that a lot of weight is good for added ballast when rolling and also maybe suggests better durability, it quickly becomes clear that a lot of weight affects the handling, as the loader needs to exert more force making it less reactive and not as nice to control.

Folding in and out

Folding the sides in and out quickly is crucial when space is limited on a busy clamp. For quick and easy manoeuvring, it often makes sense to fold the almost 5.0m wide forks. All makes bar the JCB offer adjustable throttles to control the folding speed.

For our comparison test, we left all the hydraulic systems in their particular default settings. The Bressel & Lade worked too slowly. The ProDig and VDW occupy the middle ground. Fliegl, JCB and Saphir delivered the optimum rates. The Kock & Sohn folded quickly, but not smoothly; ideally, the flow rate needed a bit of fettling or end of stroke cushioning.

Summary

Comparing these seven silage forks, there are no outright winners or losers — every fork has its advantages and disadvantages.

The implements are all pretty similar with only minor differences in design, some of which have a more noticeable effect on what they are like to use on the clamp.

A true fork all-rounder, in our view, has short tines and folds up quickly. Long tines and a wider working width are the best for shifting big amounts of material in one go, but they probably won’t be as handy on a small clamp.

The biggest difference is how well they package themselves up for transport, something we discussed in the previous issue. We all know that things often look different in practice, but safety should at least be ensured with proper tine guards, lights and warning markers, which, if they’re to be used, need to be easy to fit and remove.

THE TEST FARM

We carried out our test at the biogas plant of Ökoenergie-Recke & Co. Almost 700ha of maize silage were harvested here in 11 days, with the two harvest crews delivering around 260 tonnes of maize to the clamp every hour. On the clamp were a JCB 457S and a Fendt 930 Vario with folding blade and dual wheels. To cover any longer haulage distances, the business relies on an in-field elevator and a fleet of trucks.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.