How complicated can it be? Surely, items as relatively simple as folding silage forks can’t be that different? To find out, our German colleagues have been comparing seven different brands of these clamp-filling tools.

KEEPING IT BRIEF

- There were no winners or losers in this comparison.

- Short tines and a lower weight improve handling.

- Some of the road-going solutions are not practical.

You can have all the foraging power you want out in the field, but, if the machine at the clamp cannot keep the grass or maize away, then things will soon grind to a halt. Key to that task is the silage fork if you’re running a loading shovel.

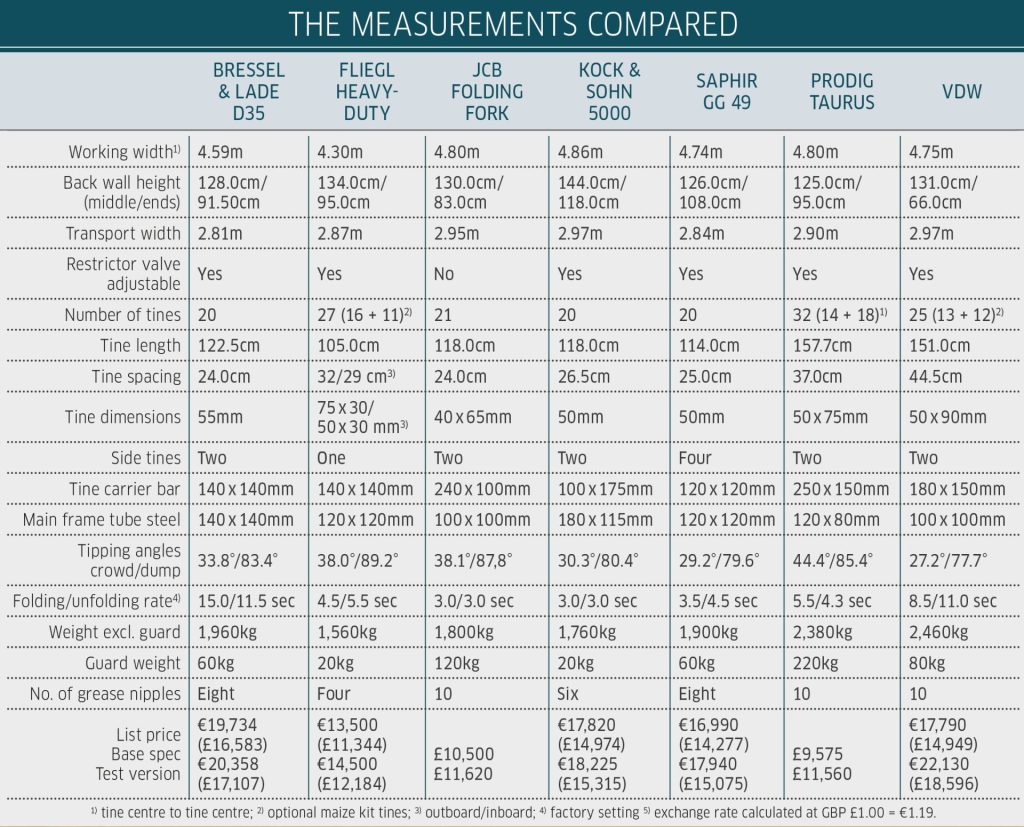

To ease road travel in between jobs, these suitably sized attachments fold in for safer road transport. Our main task here was to compare seven different marques of silage fork with a working width of 4.0 to 5.0m, with road equipment and, if available, with any potential maize clamping accessories

Now if you’ve scouted the image above, you will probably only recognise three of the makes: the off-the-peg JCB attachment, the Irish-built ProDig and Fliegl. The other four aren’t readily available in the UK or Ireland, but, just like there are only so many ways to skin the proverbial cat, there are only so many ways you can construct a folding fork. With that in mind, you may see similarities in the designs from others, or there may be some features you spot here that could well benefit your needs (or not). Anyway, without further ado…

Road guarding

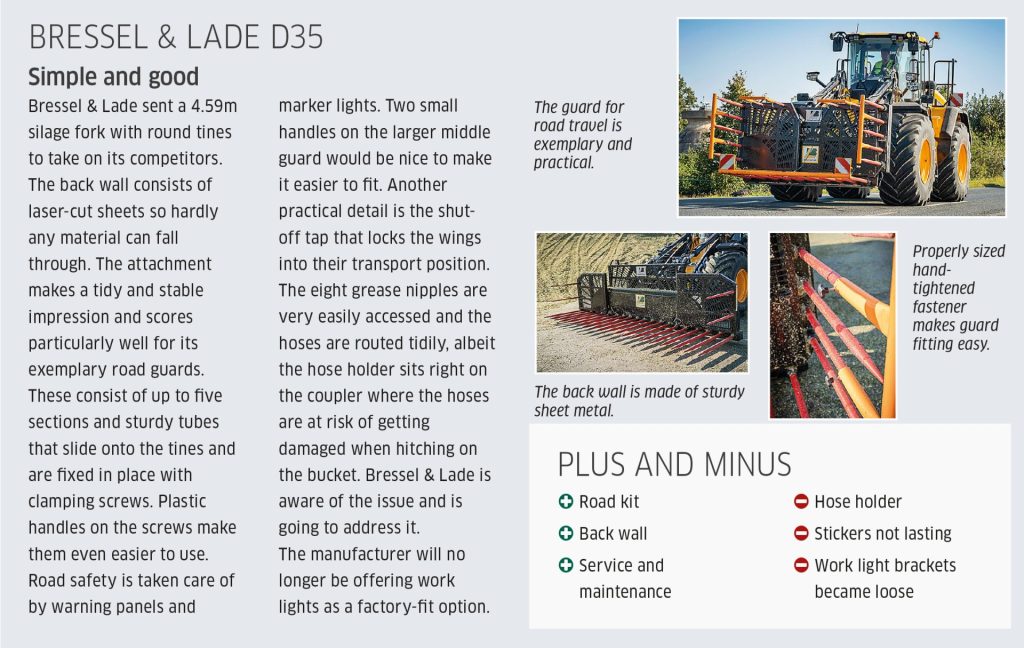

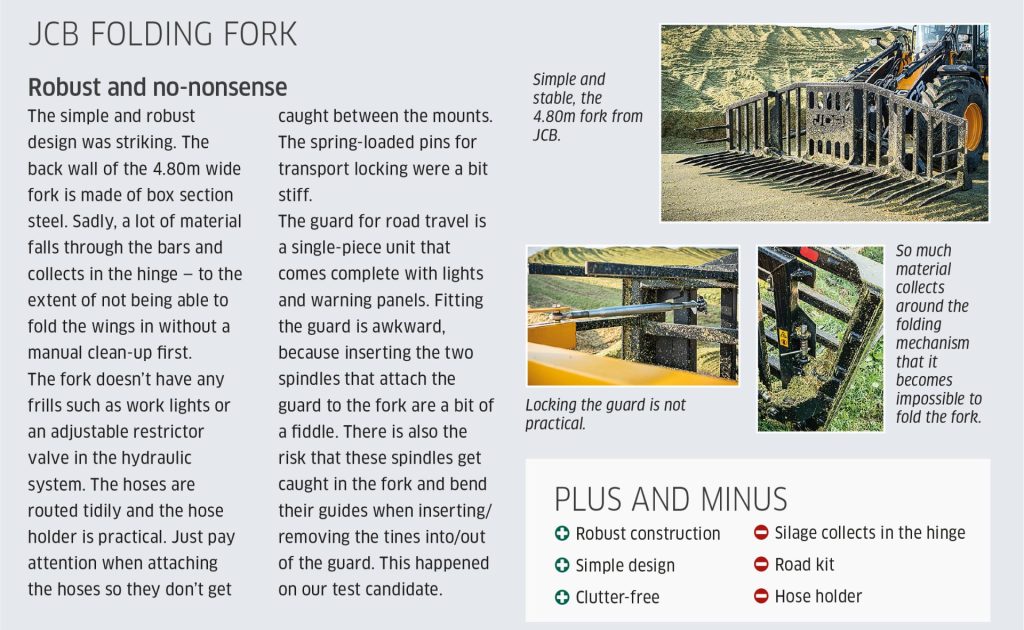

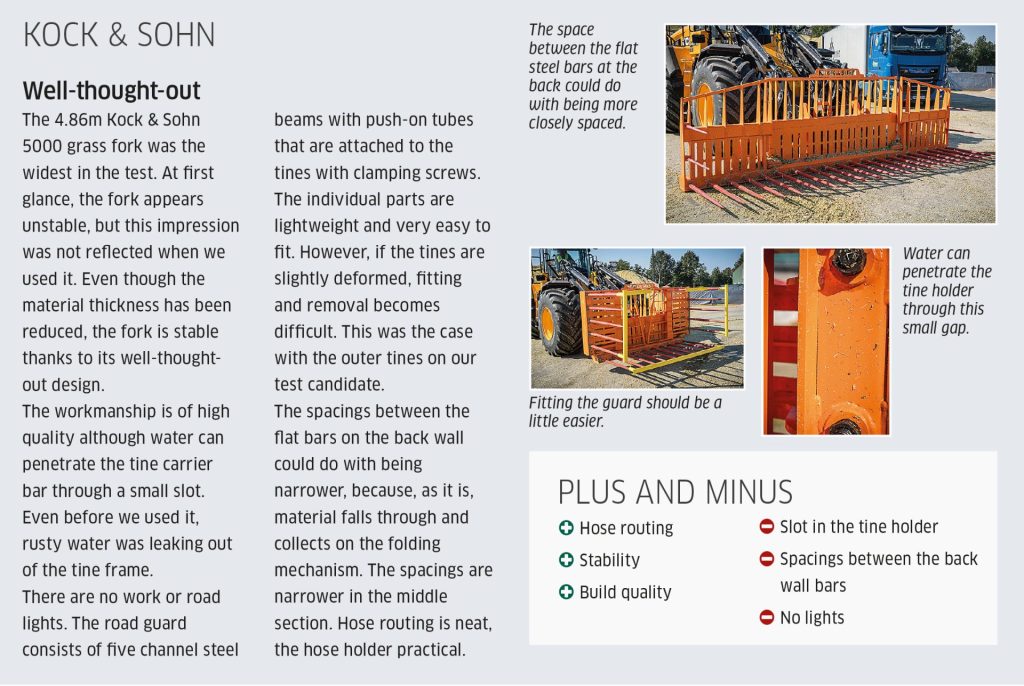

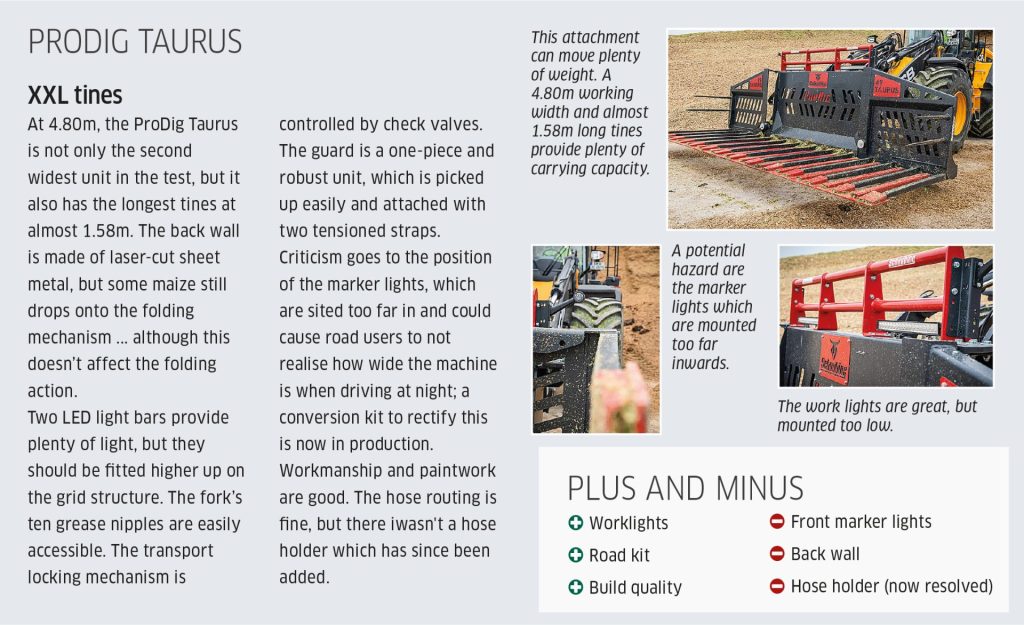

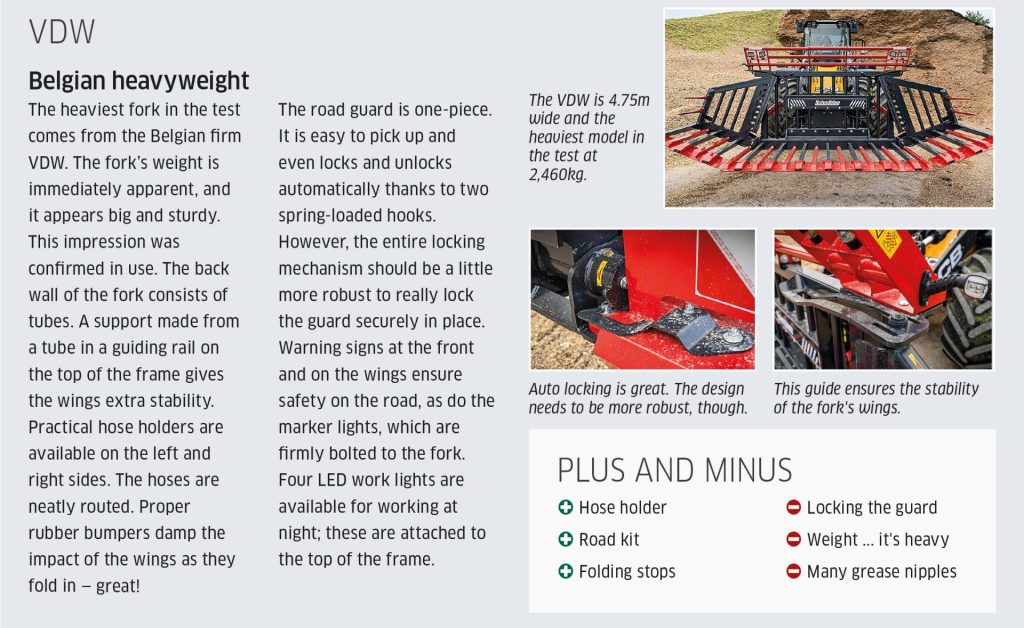

Adequate protection for the fork tines when travelling out on the road is one area that German contractors take seriously. Here there were major differences: for example, the tine guards from Saphir turned out to be totally impractical as they need to be fitted/removed with tools, making it quite unlikely that they will be regularly used. The others offer better solutions. For example, the JCB as well as ProDig and VDW (both of which are sold in Germany by distributor Schmihing) were fitted with a one-piece guard that is removed simply by pulling the tines out of it. Fliegl presented a three-piece guard that is secured in place with rubber bands.

Saphir, Bressel & Lade and Kock & Sohn use a five-piece guard that is fitted manually. Here, clamping bolts hold the protective tube guards on the tines. Bressel & Lade uses plastic-handled screws, while Kock & Sohn has relatively good metal handles. We liked these solutions, as well as the single-piece systems, as both variants are quick to fit.

Transport locking systems

To prevent the fork unfolding on the road, the manufacturers go with different safety devices. In our opinion, the best solution was from Saphir — simple clamp locks. Other solutions included hydraulic shut-off valves (Bressel & Lade and VDW), spring-loaded pins (JCB) or hydraulic check valves (ProDig). There were also notable differences with respect to road lights and warning panels, which we run through in more detail on the following pages.

Work lights

Fliegl, Kock & Sohn, Saphir and JCB didn’t have work lights, but then again we didn’t ask for them to be £11,620. Bressel & Lade supplied its unit with two LED spotlights, but the screws came loose after only a few hours. The ProDig model was equipped with two LED light bars (€690 option), while the VDW model had four LED work lights.

Yet our operators agreed that, if the loading shovel already has decent work lights, as was the case with the JCB 457S, the extra lights on the attachment aren’t so beneficial. Then again we can see the advantage on an older machine, which may well have more limited illumination.

Service and maintenance

When washing the forks, one thing became very clear — cleaning them with a maize kit installed (scraper bar and additional tines) is a lot more work due to the extra nooks and crannies that collect material. We found that large amounts of material had collected on the hinges of the JCB, making cleaning far more time-consuming. The stickers on the Bressel & Lade and Saphir forks came off. On the Kock & Sohn fork, a small slit above the tine carrier allowed water and dirt to get inside.

Grease nipple number varies between four (Fliegl) and 10 (JCB, ProDig, VDW). Access is OK for all marques. Only Saphir has two nipples on the front of the fork, where they quickly become clogged up with silage and must be cleaned before greasing. All grease nipples on the VDW fork are marked with stickers, which makes the job easier.

We will share our views on handling and using the seven forks in the July issue.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.