High speed and generally a lower power requirement, shallow cultivators can

come in many guises. Manufacturers give us a run through of what machines do what as we round up your options currently on the UK market.

KEEPING IT BRIEF

- Shallow cultivations can be used for germinating unwanted seed and/or creating soil crumb to aid drilling in dry conditions.

- Lower horsepower requirement.

- There are a selection of ‘shallow’ cultivators on the UK market: Straw rakes and knife rollers, spring tines, short disc harrows, precision tine harrows as well as shallow ploughs.

Shallow cultivation has become a popular technique with operators wishing to create a stale seedbed or to manage residues, using minimal fuel and at high workrates. There’s an array of cultivators on offer to work at less depth, using a variety of tools, which can make choosing the right implement for your needs complicated.

But first of all, suggests Horsch product specialist Gareth Burgess, consider the definition of shallow and what the aim of the operation is.

“With some systems you can barely see where the cultivator has been,” he comments. “It’s not necessarily the case that tines or discs will go in less or more deep; discs can also be used to merely crush residues such as cover crop.”

Kverneland’s Adam Burt agrees, noting that where soil restructuring is not needed, such as in the dry autumn of 2025, discs were popular as there was no need for a tine to break the pan. “They are also a good option to deal with high levels of residue.”

Cultivation intensity requirement is also important, comments Oliver Watson of Amazone, pointing out, “Cultivations can be shallow but still move soil and mix residues.”

Another consideration is the drill that will follow the cultivator.

“There’s a lot of interest in cultivators to work ahead of what was originally designed as a direct drill,” says Köckerling importer Samagri’s, Nigel Long. “If the timing of drilling and moisture levels are not perfect, it can be difficult to close the slot. But if there is some soil crumb, there’s more chance of covering the seed over.”

Kuhn product specialist, Edd Fanshawe points out that shallow cultivators offer high output for relatively low horsepower. “The Kuhn Prolander tine cultivator needs just 23-38 horsepower per metre and the Optimer disc 35-40hp. You can effectively swap 3.0m for a 6.0m shallow working implement. “

“The choice of system and depth should always reflect soil type, residue levels, rotation and drilling strategy, but when used appropriately, shallow cultivation can deliver significant agronomic and operational benefits,” says Väderstad’s Tom Wyles.

Jane Carley

STRAW RAKES AND KNIFE ROLLERS

Claydon began developing its Straw Harrow in 2007, designed to work at up to 25km/hr. The action of the spring tines creates a micro tilth in the top 30mm of soil to promote weed germination while destroying weeds at the cotyledon or one-leaf stage, removing a food source for slugs. It will also break up slug nests, dry their eggs and subsequently reduce slug activity on the surface.

“Using a part mechanical, part chemical approach is vital to help preserve valuable chemistry,” says Jeff Claydon. “On our farm, we use the Straw Harrow extensively.”

Additional tools can be added to straw harrows to achieve more of a cultivating action.

“Fitting a disc row ahead of the harrow tines makes for a dedicated cultivation tool designed for ultra-shallow, low-disturbance work,” says Ed Groombridge, marketing manager of Proforge distributor Agri-Linc. “The Pacer is particularly effective for residue mixing, weed control and surface tilth creation ahead of drilling, making it well suited to min-till and direct drilling operations.

“The addition of a knife roller at the front of the harrow on the Horsch Cultro TC crushes organic material on the surface while the harrow tines produce a small amount of tilth,” says Gareth Burgess. “Its action also mineralises nutrients and chits volunteers,”.

There’s a choice of harrow or packer behind the knife roller on the Amazone TopCut, points out Oliver Watson. “Ahead of a direct drill, the priority is to deal with residue without cultivating the soil too much as many of these drills need a firm seedbed to work into. It’s a high output operation at 20km/hr with minimal fuel usage.

Post harvest, you can use the harrow for low disturbance or the packer to produce a stale seedbed.”

Knife rollers can also be used on the front linkage of the tractor without the following harrow to destroy standing cover crops.

Another variation is Claydon’s TerraStar, which uses star points on knife bars to create 80x80mm divots in a 200mm grid pattern to create a light tilth and mulch/incorporate residues.

SPRING TINES

A shallow tine cultivator with spring tines can be used at lower forward speeds to get more mixing, points out Gareth Burgess. “It’s a longer machine so offers more straw incorporation by keeping the straw and soil in the frame for a longer period. Implements such as the Horsch Cruiser XL are available in a range of sizes, so if you want more output you can simply go wider.”

A similar spring tine in a number of formats can be used for various jobs, suggests Nigel Long of Köckerling importer Samagri. “The Hercules tine used in the mounted Köckerling Allrounder Classic is spring mounted in four rows at 15cm tine spacing. But it can be specified as a single tine or with an extra helper spring to give extra bite in dryer, heavier soil conditions.

“Swapping the packer for the hydraulic following harrows and depth wheels in the Allrounder Bio makes for very shallow cultivation,” he adds. “This is ideal for chitting operations in front of a direct style drill.”

A wider tine and row spacing aids trash clearance on the Allrounder Profiline version and with goose foot points, it can be used for a light scratch prior to direct drilling.

Oliver Watson points out that a tined cultivator can be versatile, working at shallow depth to rejuvenate soil, but can also be beefed up with heavier points for more intense soil movement or mechanical weeding.

“With 45 tines in 6.0m, the Amazone Cobra can offer very intense cultivation,” he says.

The combination of front cutting discs followed by spring-loaded tines gives the Lemken Koralin a dual action, with its disc angles and tine geometry strengthening this hybrid advantage, particularly in high-residue UK conditions, says the company.

It offers a wider (15cm) disc spacing for improved trash flow, with revised angles for more consistent slicing and reinforced frame sections to handle aggressive residue movement.

Three rows of horizontally working tines, meanwhile, can uproot weeds at depths as shallow as 2-3cm.

It is designed to achieve an ‘all over’ effect rather than leaving narrow strips of undisturbed soils or partially anchored weeds.

SHORT DISC HARROWS

Short disc harrows can offer fast, precise cultivations, incorporating large amounts of residue suggests Gareth Burgess. “They are simple to set up and offer a high output; you can choose a disc to destroy residues such as the 52cm CoverCrush, with limited mixing, or a small serrated disc for more soil movement on the Horsch Joker.”

Developed specifically to work typically from 2–5cm, while still delivering full-width soil engagement, Väderstad’s CrossCutter disc has an aggressive disc shape. Mounted in an overlapping layout, the CrossCutter achieves cutting and mixing across the entire working width.

“This makes it particularly effective for chopping and incorporating straw, oilseed rape stubbles and cover crop residues, while also encouraging rapid breakdown and even germination of volunteers,” says the company’s Tom Wyles.

In min-till and reduced cultivation systems, the CrossCutter design keeps soil movement to a minimum but can also play a valuable role within direct drilling systems, where a shallow, high-speed pass is used strategically for residue management or stale seedbed creation, rather than as a routine cultivation, he adds.

“In higher-residue situations or where cover crops are used extensively, the intensive cutting action of the CrossCutter disc ensures material is evenly distributed rather than being left in bands.”

The three-row CrossCutter disc configuration now available for the Carrier XL 425–725 and Carrier XT 425–625 increases disc density, reducing disc spacing to just 8.3cm. There’s also the option to swap out the CrossCutter Disc for CrossCutter Disc Aggressive, 450mm discs or 470mm TrueCut discs. “This flexibility allows farmers to tailor the machine precisely to their soil type, residue levels and farming system,’ says Tom.

Choice of disc can influence the result, suggests Oliver Watson. “A finely serrated or smooth disc works more consistently at shallow depth. Large X-cutter discs, meanwhile, throw soil upwards and use gravity to bring it back down, clods and stones first and the residues or weeds on top where they can chit or dry out.”

Edd Fanshawe, Kuhn product specialist adds: “Discs can be effective pre-drilling; it’s the reason that many direct drills have front discs to chop residues and work the soil slightly. It also acts as a firming up pass.”

He adds: “If you’re looking to move more soil, a small disc, such as the Kuhn Optimer may be a better option than a tine, yet it can still work as shallow as 3cm. It can work in high volumes of residue and give a consistent finish. A high forward speed is needed to get the optimum mixing effect.”

SHORT DISC HARROWS

Short disc harrows can offer fast, precise cultivations, incorporating large amounts of residue suggests Gareth Burgess. “They are simple to set up and offer a high output; you can choose a disc to destroy residues such as the 52cm CoverCrush, with limited mixing, or a small serrated disc for more soil movement on the Horsch Joker.”

Developed specifically to work typically from 2–5cm, while still delivering full-width soil engagement, Väderstad’s CrossCutter disc has an aggressive disc shape. Mounted in an overlapping layout, the CrossCutter achieves cutting and mixing across the entire working width.

“This makes it particularly effective for chopping and incorporating straw, oilseed rape stubbles and cover crop residues, while also encouraging rapid breakdown and even germination of volunteers,” says the company’s Tom Wyles.

In min-till and reduced cultivation systems, the CrossCutter design keeps soil movement to a minimum but can also play a valuable role within direct drilling systems, where a shallow, high-speed pass is used strategically for residue management or stale seedbed creation, rather than as a routine cultivation, he adds.

“In higher-residue situations or where cover crops are used extensively, the intensive cutting action of the CrossCutter disc ensures material is evenly distributed rather than being left in bands.”

The three-row CrossCutter disc configuration now available for the Carrier XL 425–725 and Carrier XT 425–625 increases disc density, reducing disc spacing to just 8.3cm. There’s also the option to swap out the CrossCutter Disc for CrossCutter Disc Aggressive, 450mm discs or 470mm TrueCut discs. “This flexibility allows farmers to tailor the machine precisely to their soil type, residue levels and farming system,’ says Tom.

Choice of disc can influence the result, suggests Oliver Watson. “A finely serrated or smooth disc works more consistently at shallow depth. Large X-cutter discs, meanwhile, throw soil upwards and use gravity to bring it back down, clods and stones first and the residues or weeds on top where they can chit or dry out.”

Edd Fanshawe, Kuhn product specialist adds: “Discs can be effective pre-drilling; it’s the reason that many direct drills have front discs to chop residues and work the soil slightly. It also acts as a firming up pass.”

He adds: “If you’re looking to move more soil, a small disc, such as the Kuhn Optimer may be a better option than a tine, yet it can still work as shallow as 3cm. It can work in high volumes of residue and give a consistent finish. A high forward speed is needed to get the optimum mixing effect.”

THE SHALLOW PLOUGH

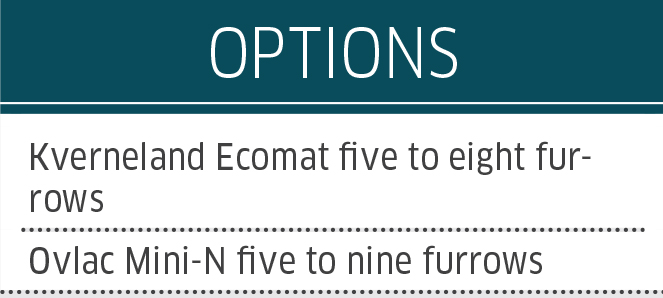

Where full inversion is the requirement, a shallow plough can bury residues without needing to work deep, comments Kverneland’s Adam Burt.

“For example, vegetable growers need a quick turnaround and clean seedbed between crops, so the Ecomat shallow plough has proved popular to work just the top few inches ahead of a power harrow.

For more up-to-date farming news click here and subscribe now to profi and save.