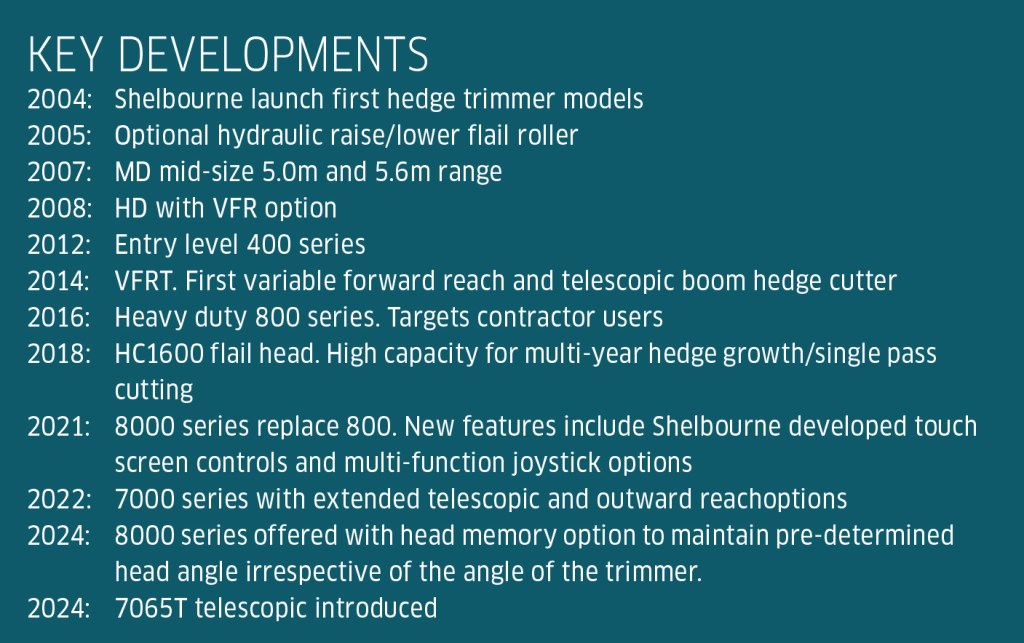

Shelbourne Reynolds started volume production of its 5.0m Powerblade hedge cutters in 2004, the company having since expanded the range with models up to 8.0m reach. Add a choice of telescopic and variable forward reach, plus different flail heads, and there is a lot to think about when looking for a used buy.

If measured end to end, it is estimated that the hedgerows in just England would be long enough to go around the Earth nearly ten times. Accepting that not all hedges are maintained, that will still leave a significant mileage of hedge that needs trimming annually. Add summer verge mowing, and many contractors can rack up 2,000 hours plus of hedge cutting and mowing a year. Three year hedger replacement cycles are common as a result and this in part explains why young high specification ex-contractor hedge cutters are a likely used find. If your needs are for something simpler, then many of the used examples out there could be older but have done less work. Buying a used hedge cutter is perhaps more involved than you might think.

Shelbourne Reynolds hedge cutter models have evolved over the past 20 years to reflect changing demands. Where once a 1.20m flail head was deemed adequate for most general purpose needs, wider 1.50m and 1.60m alternatives able to tackle two years plus of hedge growth are now common spec choices. As to hydraulic motor power, think 70hp or 85hp as now common, 50hp, as used on the 400 series, now being considered as entry level. Shelbourne opt for high oil pressures over hydraulic flow for its machines. As a guide, flow rates will be between 100 and 125 litres/minute, with pressures of up to 275bar at the rotor and 225bar for main functions controlling the trimmer rams.

Farm, as opposed to just contractor buyers, are also increasingly opting for the company’s higher capacity models from new, with the current 7000 introduced in 2022 and range topping 8000 series launched in 2021 now listing as the top sellers. Predecessor 700 models from 2012 and 800 models first available from 2016 form the template ‘7 and 8’ series and it is these models that will now make up the bulk of used models on offer. That said, mid-size 600 series models, launched in 2014, remain popular, with the current 6000 series arriving around eight years later.

At the lighter end, the 400 series have a following as they are suited to working with smaller and lighter tractors. Launched back in 2012, the 400 models are based upon the original Powerblade series but as with all variants have benefitted from updates in the interim.

NOTE: 200,300,500 series have been discontinued over the years, with the 400 and other models as listed making up the bulk of used finds in the UK.

Breaking the code

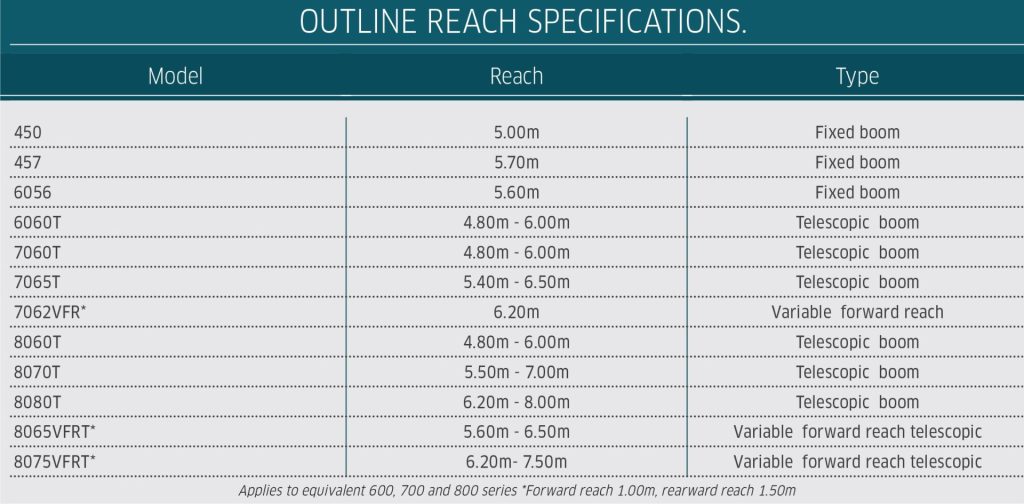

The series number Shelbourne use is just that, with the reach shown by the last two digits of the model number. As an example, a ‘6 series’ 656 or later 6056 will have a true 5.60m of reach. If the model number has a T at the end, it has a telescopic dipper, a 6060T extending out to 6.0m but just 4.80m when fully tucked in. The other model letters to consider are VFR for variable forward reach, with VFRT adding a telescopic dipper.

What to look for

Job one is to try and look over a machine that is hooked up to a tractor. Although it is fair to expect a dealer prepared used buy to have been prepared for sale, it is still down to you to check the machine over. This is only possible if you can run it up and work through all the various functions. As for checks, the simplest approach is to look over the machine in the same way that you would in preparing it for work for the first time in the season. That said, it is easy to miss something so following a set check pattern can help.

Start with the flail head as this provides a good indication of how much work the machine has done. Although the 700/7000 series may have an LED indicator on the controller that will list service hours, the head will show how hard those hours have been. Contractor machines can rack up huge hours but if those have been trimming regularly maintained hedges the wear on the machine will be less than a unit that has done a lot of heavy cutting and verge work over rough ground. Key checks should include:

Flail

Condition of the head body. Made from 3mm thick steel, the heads are tough. If severely battered this will tell you all you need to know. Paint finish is typically good, Shelbourne switching to a powder coat system back in 1999. Continued investment into the metal preparation has further enhanced the longevity of the paint finish. An automated powder booth was added late in 2024.

Bearing wear in the main rotor. Picking this up is easier if you can use a bar to pry the shaft. The drive motor bearings have a two-part design to help reduce wear on the motor drive shaft.

Rear roller bearings work hard on verge mowers. If the unit is just used for hedge cutting, wear here will be less of a concern but still check.

The front hood flap is liable to damage. If bent, it may be harder to adjust. If hydraulically adjusted, open and close the flap and ensure it works as expected.

Flails are obviously a wear items. When worn, they should be replaced as a set to help ensure the rotor remains in balance.

Boom and dipper

- Shelbourne has increased the number of grease points on its machines over time, with two grease nipples per long pin to ensure lubricant reaches more of the the bush. The pins are solid, with a securing location bolt. Check this is in place. Bush play is obviously a key check but one you can only do if the hedge cutter is mounted on a tractor.

- If the main boom lift ram has a swivel top joint, it needs to be greased. The main pivot also needs greasing but the nipples are only accessible from certain angles so may be overlooked. Check for evidence of routine greasing.

- Break-back can only offer a degree of protection, so look for any bends or signs of impact damage on the boom and particularly the dipper. On telescopic models, extend the dipper fully and ensure it retracts without any sign of binding.

- On variable forward reach models, work through the full range of movements including when working at height, looking for signs of damage.

- The flail pivot works hard. Pivot wear is easily remedied but less so if wear has progressed beyond the replaceable bushes.

- Shelbourne originally fitted an attachment plate to attach the head. Later models will have a hook link system that makes it easier to bolt the head to the dipper. Swapping to alternative attachments may be possible using an adaptor plate.

Hydraulics

- First check is the hydraulic oil tank, this having a capacity from 170-litres on the 400 series and up to 230-litres on the 8000 series. The level gauge should be between the min and max points when the machine is cold. If the oil looks dirty find out when it was last changed.

- The oil cooler has a removable screen on larger models. This will trap a lot of debris, a periodic check and clean keeping the radiator itself clear. Remove and check.

- The hydraulic tank filter has a pressure gauge incorporated in the housing. If this reads deep in the red when the unit is running, you will know the filter is blocked. It needs changing once a year or every 500 hours.

- Shelbourne fit four and six wire hydraulic hose. Due to the high system pressures used in the hedge trimmers it is extremely important all hoses are replaced with the correct hose for the job. If a hose shows signs of damage or wear through rubbing it should be renewed. Also check the fabric covers where fitted. These can trap debris if left to run when torn.

- The main hydraulic pump will be 50hp on the 400 series, 70hp on the 600/6000 and 700/7000 series and with 85hp option on 7 and 8 series. Apart from checking the pto driving the pump, it is hard to detect if the pump itself has any problems. A dealer will be able to do a pressure and flow test.

- Ram seals do wear over time so look for oil weeps and damaged chrome on the ram piston. Poor storage can lead to problems.

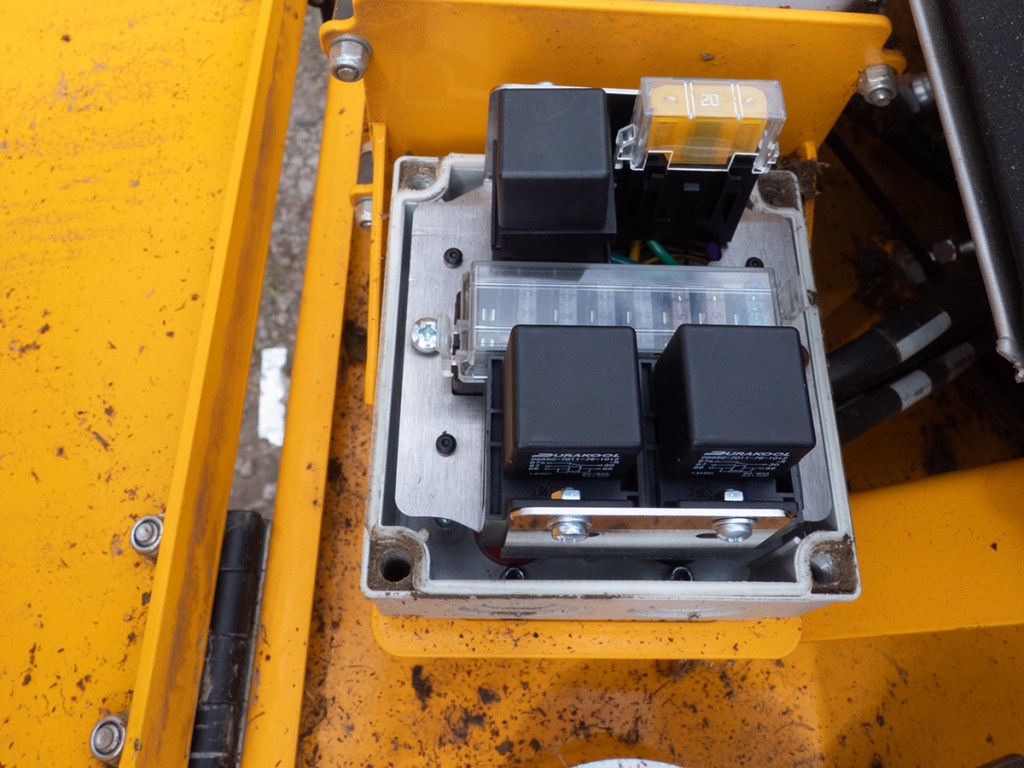

Electrics

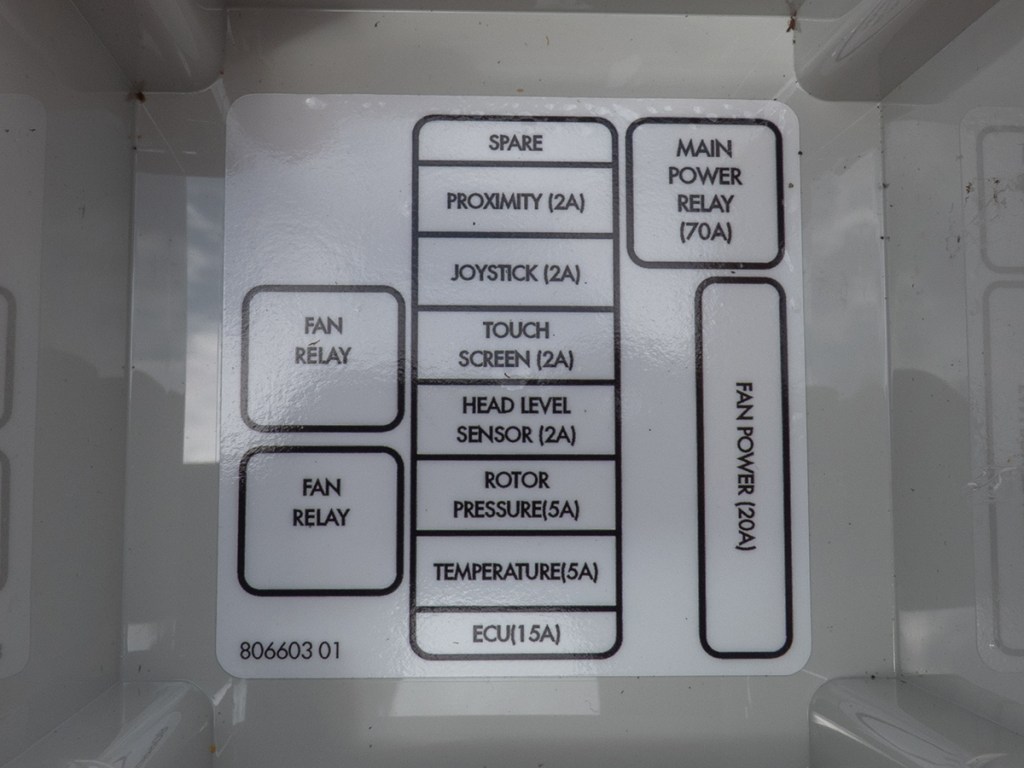

- Power to the cooling fan is direct from the tractor battery as it has a high current draw. The connection is protected by a 40amp fuse at the battery end, with a second 20amp fuse in the fuse box. Check the fuse box for water ingress, which will be rare.

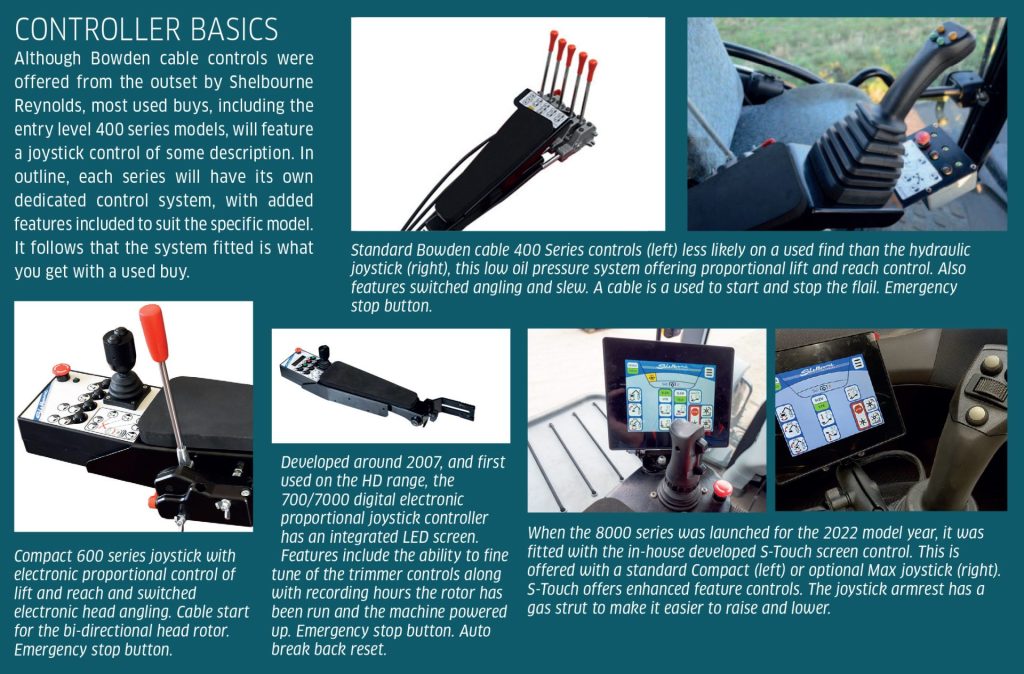

- The controllers plug into the main wiring loom via a connector that will need looking over if you suspect any problems with any inputs. Damage as opposed to wear is the key problem with wiring looms.

- As with all functions, the only way to check the electrics is to hook the machine up and try everything including the lights. LED lighting is now standard, with replacement light units more reasonably priced than like for like items fitted to many tractors these days.

Summary

Is that it? Partly yes. Looking over a hedge cutter is not as time consuming as on other bits of kit and you can access almost everything with the help of a 19mm spanner. The main issue is specification and matching the machine to the tractor you are going to use it with. Attachment brackets make fitting a Shelbourne machine easier than on some competitive designs, with dealers typically having the experience to supply a fitting kit to suit different tractors where applicable.

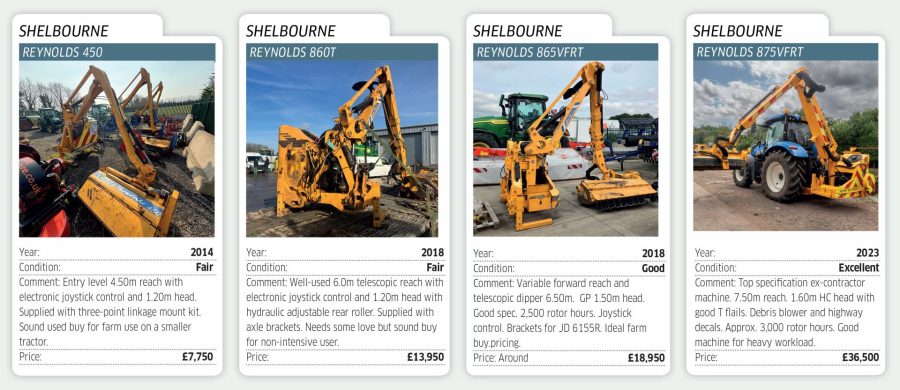

As to used prices, you get what you pay for. If you are after a 400 series expect to pay around £7,500 for a sound example in good condition and ready to go, £16,000 plus securing a larger 6000 series with a good spec and in tip-top order. The latter price will buy a base spec 7000 series in good order.

With thanks to Neil Smith, Adam Whitaker, James Swinstead at Shelbourne Reynolds Eng Ltd, TBS Ltd, Great Barton and Farol Ltd, Milton Common

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.