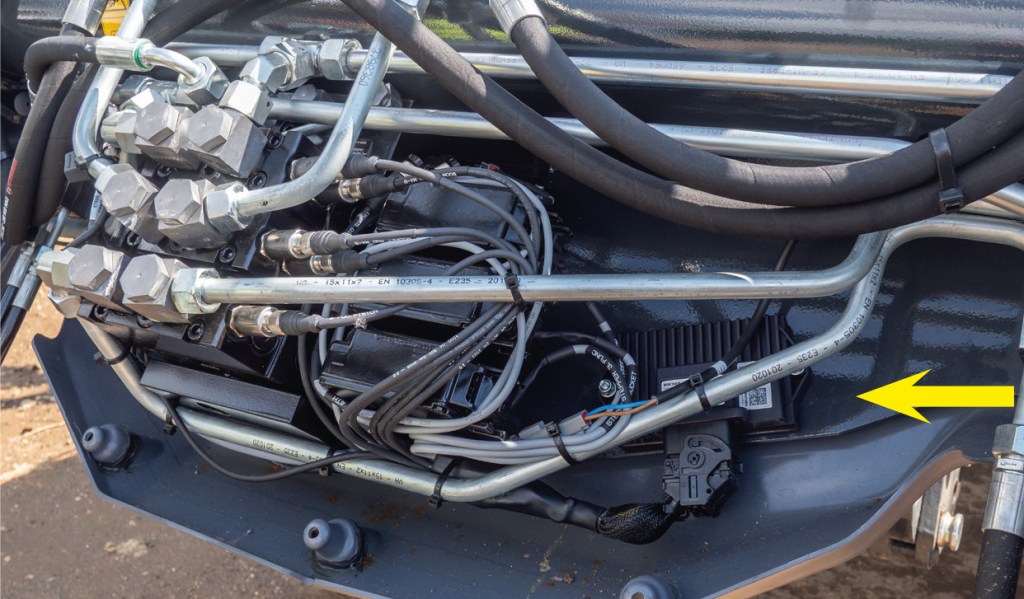

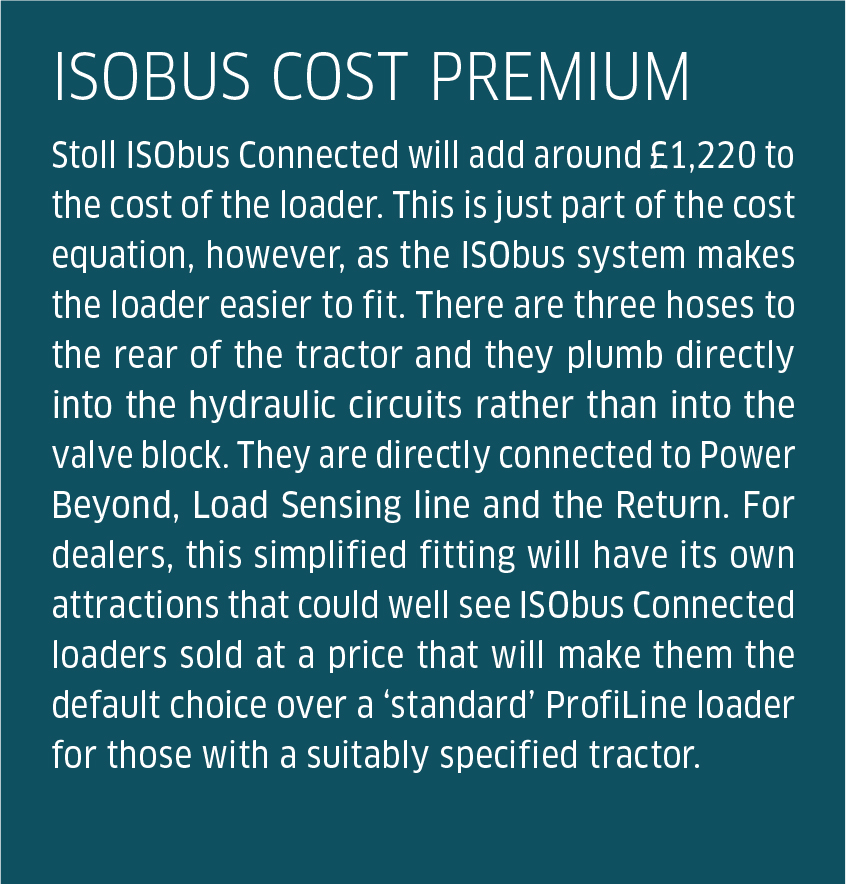

Stoll’s ISObus Connected loader controls is now an option on the ProfiLine range making it not only easier to install and use via the tractor’s onboard joystick and ISObus terminal. With this simplified integration, installing a loader is easier but this is just part of a bigger story.

KEEPING IT BRIEF

- ISObus Connect is only offered on Stoll ProfiLine loader models

- Basic set up offers smooth loader control

- Fitting a loader to a suitable tractor will take less time

- System adds weigh system to a Stoll loader for the first time

Stoll has packed a whole host of operator-friendly features into its ISObus Connected system. While none are absolutely essential, half an hour into using a ProfiLine FZ46-29 on the nose of a JCB Fastrac 4220 it was clear there is more to the set up than the features that come as a package with this ISObus system. Even a ham-fisted joystick jockey can become a smooth operator.

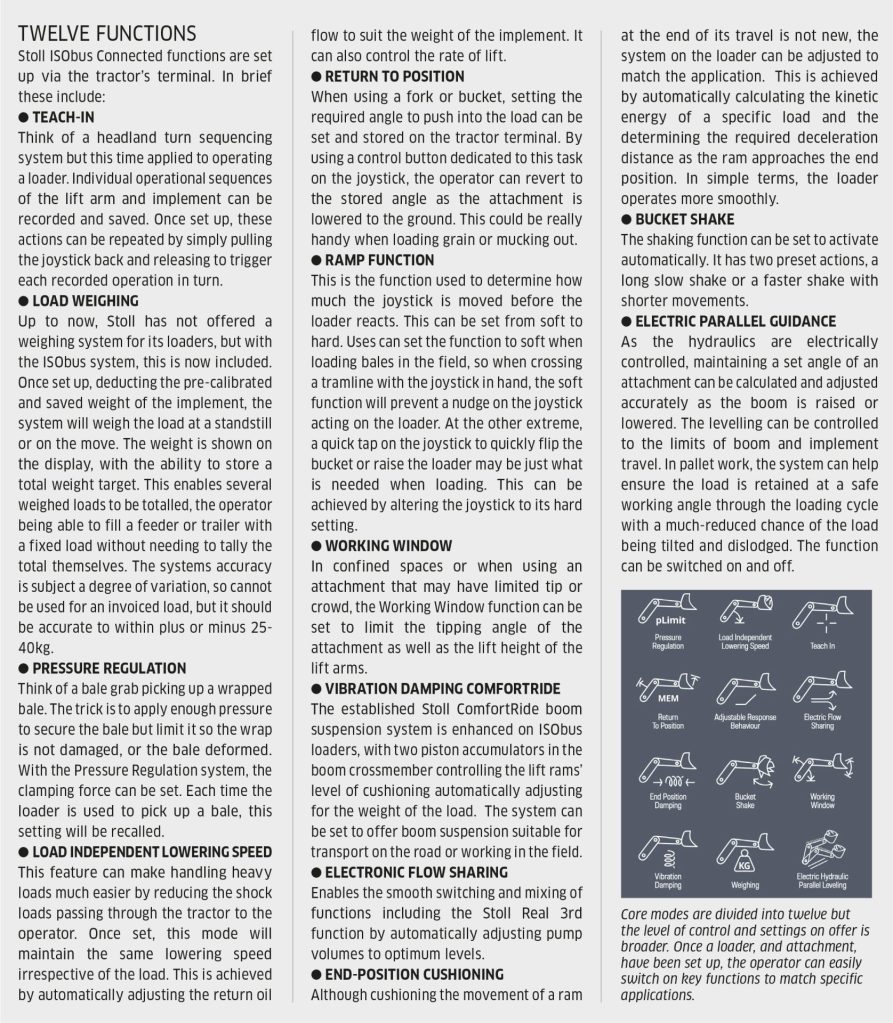

ISObus Connected can be set up to operate in different ways to match specific tractor models, but for most the loader will be operated via the secondary joystick that is part and parcel of many modern tractor controls. A few tweaks and operating the loader in its simplest mode will have most operators up and running with very little in the way of instruction. According to Stoll’s long-established UK importer Lynx Engineering, most of the ISObus Connected loaders it has sold to date have seen customers get used to the loader initially by operating it in its basic Easy Mode setting.

Once familiar with the basics, operators can then dive into the various set-up profiles that enable various functions to be tweaked, not just in general, but to suit specific attachments and tasks. These can then be personalised to suit different operators – a possible useful feature for tractors is used by different drivers.

Sounds great, but what is it like in practice?

Lynx Engineering had two ProfiLine loader set ups to try; a JCB Fastrac and Case IH Puma 165. This provided an opportunity to sample the ISObus Connect set up patched into the integrated ISObus system of two different tractors. In both cases, the mini joystick fitted in these tractors was set up for operating a front linkage plus spool valves selected by the operator. Thanks to ISObus, the joystick is easily assigned to operate the front loader.

Using a mini joystick to operate a ‘conventional’ front loader can be a somewhat ‘jerky’ affair, a lack of accurate proportional control sometimes making it difficult to accurately position a load or work the loader in the field over rough ground. With the Stoll system, the sensitivity of the joystick and the way the loader hydraulics are controlled can be easily tweaked. This made working the loader if not necessarily easier, then certainly smoother. This was particularly noticeable on the Fastrac, the front suspension of the latter having far less work to do in soaking up the shock loads of the loader as it was brought to a stop at speed with a filled bucket. The loader ram end stop cushioning was adjusted to help dampen the loader as it reaches a pre-set lower stop position to sample what it could do, regardless of load in the bucket, it worked well.

Diving into the loader specific menus did initially seem complex but, as is always the case with ISObus set ups, a short while working through the settings a couple of times and operating the loader as each change was made soon made it easy to navigate through the core settings on offer. Once set up, the settings are retained, with the option to have a range of set-ups to suit specific applications or operators.

Regardless of the settings on offer, it was the ability to work the loader smoothly that was the standout feature. Being able to automatically programme in a set up to match the job, such as return the bucket to level at a specific boom height and controlling the dump speed when tipping is the just one of the cherries on top.

Nick Ewbank, managing director of Lynx Engineering, suggests that the market for the new ISObus compatible loader will suit a range of operators. “The benefits ideally suit tractors from 120hp plus”, he says. “As an example, having a loader that can weigh individual ration ingredients and add up total weights has obvious advantages. Programmable working heights and setting the loader up to complete repeatable operations can boost productivity. Another simple example is in the handling of wrapped bales. The ability to program the squeeze pressure of a bale handler to reduce the chance of bale deformation is just one key advantage of a programmable loader and its attachment”.

Summary

Matching a tractor to a front loader can see a compromise between ease of attachment and its control, an integrated loader joystick not always offering the finesse that makes the loader pleasant to operate. The Stoll ISObus connectivity system scores by enabling the operator to set up the loader so its sensitivity can be matched to a specific application with the accurate control of the loader hydraulics to make it easier to smoothly operate.

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.