If you want to take farm engineering to the next level and regularly cut various pieces of sheet steel, then a CNC plasma cutter might not be a ridiculous purchase. We take a look at what hardware British firm Swift-Cut can offer, with the technology to match.

KEEPING IT BRIEF

- Founded in 2011, Swift-Cut is based in Burton-on-Trent.

- Tom Lamb has recently invested in a CNC plasma cutter.

- Swift-Cut is offering profi readers the Pro 1250WT package at a special introductory price of £15,995 rather than the usual £18,995.

Farm workshops, very much like farms themselves, range wildly in both size and the levels of equipment available, often ranging from a small workbench tucked away in a quiet corner somewhere to a purpose-built unit full of metal forming gear.

Regardless of which particular scenario you find yourself in, given basic tools, and, with a little patience and skill, even reasonably complex fabrication is possible. Talking from experience, armed only with a drill and grinder, I too have employed the ‘hillbilly lathe’ to shave a few mil off the occasional oversized pin. As proud as I may have felt, having snatched victory from the jaws of defeat, there is still nothing quite like having the right tool for the job, facilitating both precision and timeliness.

One such fellow to have fully embraced technology and the benefits it can bring is farmer and YouTuber Tom Lamb, who kindly invited profi to a demonstration of his new Swift-Cut CNC plasma cutter, with assistance provided by Swift-Cut’s marketing manager, Dan Page.

What is a CNC plasma cutter?

Quite simply it is a computer-controlled cutting head working in a flat plane above a table style bed, capable of precision cuts in a variety of sheet metal.

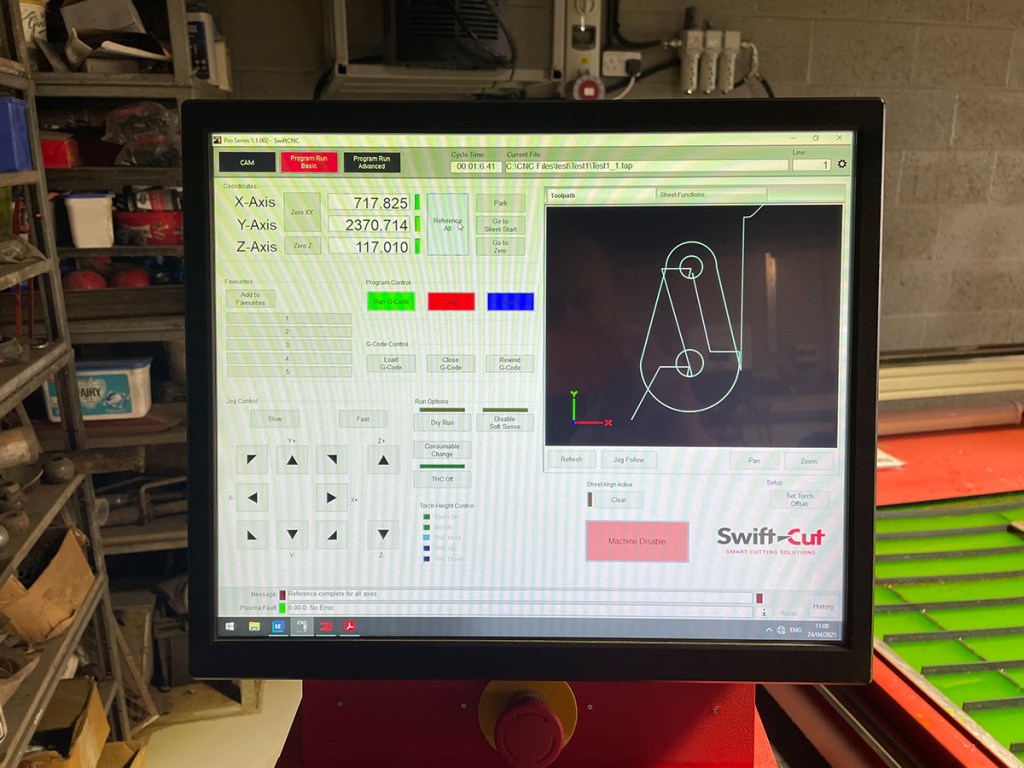

Don’t be put off by the ‘computer-controlled’ aspect, as every effort has been made by Swift-Cut to simplify its intuitive design and cut programmes, facilitating the various steps between blank canvas and finished part. In addition, 89 design templates come pre-loaded, with the handy option to adjust key dimensions and values to quickly match those required.

However, I was most impressed with the software’s ability to create a replica design from a high-contrast image. In other words, take a good photo of the part you wish to replicate and let the software do the rest. Clever stuff.

Despite the firm’s best attempts to remove as many as possible, should you still manage to run into a stumbling block, help is at hand, as Swift-Cut staff is able to take remote control of your machine for troubleshooting.

Whichever route you take to produce your design, options to ‘nest’ duplicates on the same sheet are then offered, with the system asking what thickness of material you intend to cut and returning the size of cutting cartridge needed at the business end. These cartridges are consumable parts, a selection of which are provided with the machine.

Off you pop

Once started, plasma amperage and travel speed are all taken care of automatically, with the water in the cutting bed serving as fume suppression. As a bonus, the water also acts as a heat-sink, keeping parts cool during cutting to prevent any warping and allow immediate handling.

Having burnt out my fair share of grinders, the significant benefits provided by CNC cutting become glaringly obvious as, once programmed, the precision parts could be repeatedly churned out without supervision.

Theory into practice

This ability is exactly what existing Swift-Cut customer, Sanderson Steel Structures, has been taking full advantage of, turning sheets of plate steel into a plethora of cleats, end-plates and gussets, all complete with accurately positioned bolt holes. Albert Sanderson, company director of the Skipton business, was keen to emphasise that, once programmed, the machine frees a member of staff to make an early start on fabrication work, raising productivity and helping the company see a return on investment within the year.

Rather like purchasing any other machinery, here lies the crux of the matter — should you want one, can you justify it? For those in the fabrication business it would appear a ‘no brainer’, but for the more occasional user in the farm workshop it may not be so clear.

Realistically, how quickly will you see that ROI? Helping clear the waters somewhat, Dan Page expected to see typical running costs in the region of £9 per hour, including consumables, which compares favourably with skilled labour at £20/hr before adding any consumables. That skilled labour not only needs to bring their A-game in order to produce comparable levels of precision but also spend valuable time measuring and marking, especially when holes are required. Even if armed with a mag drill, boring holes in metal plate is not only time consuming, but somehow both mind numbing and a little nerve wracking.

Something that is far more difficult to put a monetary value on is the timeliness afforded by running your own machine and being able to turn out parts as, and when, needed. A detail not lost on Tom, who stated it helped to justify buying his own machine.

How much?

Now it’s time for the nitty-gritty, what is a realistic on-farm price and what do you get for your money? The Swift-Cut Pro package starts with the 1250WT at £18,995. This includes the 1,250mm x 1,250mm water filled cutting bed, a Hypertherm Powermax45 SYNC plasma power source that’s capable of running on single phase, and a computer terminal. Installations do require a good supply of dry compressed air, so, if the workshop compressor is a little tired, factor in the cost for its replacement, too.

Nigel Thornborrow

For more up-to-date farming news click here and subscribe now to profi and save.