Derbyshire business T H Flower and Partners milks 350 cows in the Peak District. With a forward thinking approach, the outfit averages 13,600 litres of milk per cow.

The Flower family is based between Buxton and Matlock, nearly 1,000 feet above sea level, on a ridge of limestone. This elevated position can have some benefits such as remaining dry, but it also brings its challenges when rain fails to fall in the summer and exposure to the elements. That said, the dairy business is forward thinking and tries to capitalise on the challenges rather than fight them.

Ed Flower runs the farm, while mum Sue and dad Tom are still involved lending an ear and a progressive mentality when needed.

With another generation of the Flower family growing, the farm is in constant evolution. A new cubicle shed has been built in the last two years to accommodate dry and close-to-calving cows. The business keeps pace with technology and continually looks to improve infrastructure whenever possible.

Animal welfare is high on the list of priorities: happy cows make more milk, and healthy cows are easy to keep happy. The yield of 13,600 litres per cow is not to be sniffed at, so the Flowers are doing something right, or rather lots of little things, that’s adding up to healthy gains.

Structure

The cows are housed year-round and are fed TMR with supplemental meal in the parlour; milking is three times per day and feeding is done once, with feed frequently pushed up. Youngstock and followers are reared on the farm.

Silage is made in four to five cuts of 100 hectares, weather depending, and the crop is harvested with a forage wagon. This suits the geography of the farm, and they get on with the wagon length of cut, too. For whole cropping, the business also grows spring cereal crops.

Slurry

Separating slurry has been part of the farm’s routine for about 15 years, but in the past five a Fan Green Bedding separator has been installed.

“We were set up for separating, so it made sense, when the old separator reached the end of its life, to go down the green bedding route,” points out Ed Flower.

Like many, the Flowers found that the price of sawdust was increasing with demand for power generation, and the product quality had decreased at the same rate as the price going up. Switching to green bedding was straightforward, as everything was already there; it was just a case of learning the best way to utilise the material. The cubicles are topped off every day, with little and often seeming to be the trick.

“We had a bit of a spike in the cell count when we switched, but we worked hard on hygiene and consistency with the bedding. It came back to base level fairly quickly,” recalls Ed.

With a limestone bed under the whole area, it’s not hard to get lime. It is supplied by a local quarry in bulk. The ground lime makes for a respectable saving over 25kg bags on pallets and also provides equal sanitising properties. This is dispensed three times per week.

On the land

With 350 milking cows plus all the other animals on the farm, there’s plenty of slurry, so any extra separated fibre is stockpiled outside to rot down for spreading as manure. Some is applied to the silage ground after rotting down, while the rest goes on the 40ha destined for wholecrop. Due to their height above sea, there is no maize grown in the area.

The liquid element of the slurry is handled by an umbilical system on the land around the yard and by tanker and dribble bar on the outlying land. The grassland strategy is to reseed every five years, this keeping the leys fresh. “We’ve noticed a dip in pH after four years, which naturally impacts on the growing capacity, so we apply plenty of solids and reseed, using wholecrop as part of that rotation,” says Ed.

The main cow house

The largest of the cubicle sheds is 15 years old; this is where the milking cows live, with all milkers running as the one group. The building has seen some significant changes over recent years, with the most recent addition being a light ridge.

This upgrade was designed in partnership with Lancs-based Shield Agriculture, which helped organise the update. The structure of the building wasn’t changed significantly, but the top two rows of roof sheets either side of the apex had to be removed.

What was put back in their place was a raised ridge like a squat greenhouse; it’s about an extra metre taller than the existing roof at the peak.

The whole ridge is translucent, built on its own frame with weather-protected vents to facilitate airflow, the idea being that the ventilated light ridge creates a microclimate in the roof of the shed to give the already warm air a boost. It draws the air upwards faster, which in turn pulls fresh air in through the building’s sides. As well as the increased air circulation, there is more consistent light in the building, because the ridge is raised. And there are none of the hot spots that roof lights produce.

There are fans in the shed; originally three were fitted, which were 6.0m in diameter.They improved the situation, but five more were added, and all were fitted with 5.0m blades.

Yet it was the addition of the light ridge and side curtains that ultimately created the best environment. The side curtains are from Huesker, and on the main cubicle shed these are the bottom-up type. They’re automatically controlled via an external weather station, which senses rain and wind, closing most frequently with rain, keeping the cows dry. If there is an exceptionally strong wind, they close, too.

What attracted Ed to the Huesker curtains is their solid guide system, which has been well tested by the howling winds of the Peak District, and there hasn’t been any hiccups. Nets have been fitted to the side of this building due to a starling issue, which seems to have been enough to deter them. With no clear flight path through the building, they stopped coming in.

The shed underwent a massive upgrade for an automatic scraper system. This was to reduce any digital dermatitis and increase cleanliness in the busiest building. Installing a slurry channel in the two main passages was quite the undertaking, as the channel runs the full length of the passages.

The aim is to reduce the ‘tidal wave’ of slurry as the new Storth automatic rope scrapers work their way down the building. As it happened, the scrapers were working while we were looking at the building, and there was minimal surge from the scraper, as the channel took the bulk of manure. The cows didn’t seem bothered in the least.

The business is part way through rotating out the older mats. The main cow house has Wilson mats and the new cubicle shed has Kraiberg mats installed, with a cleanliness benefit to the latest mats, as the passage side is sloped to aid run off. It’s thought that these will go in the milking cow shed, with the thinking that the cows that let milk down while lying will stay drier and cleaner. Both systems appear to provide high levels of comfort.

The milking parlour has been rigged out with Kraiberg matting also; like humans, cows prefer to stand on a soft surface, a bit like having carpets. The cows stand more quietly in the parlour due to reduced pressure on the hoof, and the mats provide more grip than concrete.

“They’re good, and really make a noticeable difference. If a cow does decide to take off, she can still slip, though this does save the slower slips and prevents many incidents.”

With every benefit comes a cost, and that is to get the parlour floor clean it needs a high-volume wash out. Part and parcel of most parlours, the high-volume hose does a good job on the mats, and gets all of the visible excretion out of the matt grooves. Ed also said the mats protect the concrete somewhat from the chemicals used for cleaning the parlour, and the rubber doesn’t seem to be impacted as much.

The new build

Finished in 2025, the latest cubicle building was added to house the dry and close-to- calving cows. This freed up space for the heifers to be kept together in a different building, the expanding herd needing some more space.

The frame was grafted to another building, so isn’t freestanding, but it and everything under it are new. Like the main cubicle shed it has a light ridge; this was part of the build so was considered at planning stage. It has the same pluses as the main cubicle building in that airflow in the summer is managed. In this case, however, though there are no electric fans, so running costs are lower.

On the sides of the 2025 building, Heusker curtains were used, but top-down instead of bottom-up. Like the main building these are self-monitored, with the environmental station making decisions. There are two sets of coupled sensors — internal and external — that feed in information about weather, temperature, humidity and building status, affecting when and how much the curtains are open.

Inside are Agriprom release cubicles. This flexible system enables all the cows to get comfortable while reducing any potential for pressure points. The system allows for a greater variation in cow size and age, as the dividers guide the cows to lie in the right orientation rather than force them. Comfort increases times for rumination.

Less critical in this building as the cows aren’t milkers, but the system should prove the theory, and whether it’s cost effective to set out the main cubicle shed with flexible dividers when the existing hardware needs to be replaced.

The mattresses within the new building are Kraiburg Kew Plus, a three-layer system that offers high levels of comfort and also has the benefit of a sloping rear edge which increases hygiene dramatically. The mats dry quickly which helps with cleanliness.

In the passageways the grooving was done after the concrete was dry.

“We prefer to do it that way. Rolling a texture into wet concrete doesn’t leave as much grip as cutting it in,” says Ed. The wet method is more cost effective but also leaves a more difficult surface to scrape and clean than a cut finish.

Teemore Engineering fast-empty drinkers were fitted and have worked well. Ed says they still need a swill round with a soft brush to maintain them. It’s not quite as simple as draining them, though the 76mm valve does empty the trough quickly and pulls debris and left-over food from the cows’ mouths down the plug effectively.

Sun and water

T H Flower fitted solar panels to its roof area in recent years; there is currently 200kW of generating capacity and 100kW of battery storage. With three milkings per day, this means that in the summer the farm only has to pull from the mains grid for the morning milking, as the battery is depleted during the night.

Tom Flower says the next logical step for the firm to mitigate energy costs and have round-the-clock power would be to add a manure-only digester, which would complete the full circle for the farm in terms of self-sustainability. At this stage it’s just an idea because of the capital expenditure.

That said, with 350 milking cows and their youngstock on the farm, the head count would be ideal for a 50kW system. That would generate 1,200kWh every 24 hours, enough to not draw from the grid at all, and add a revenue stream to the business by selling excess electricity.

As well as modern dairy farms being quite energy hungry, they are quite thirsty, too. Tom installed a well when he was younger, and another has been added. They’re maxed out now, so the theory is to add a larger well that will mostly satisfy the farm, with top- ups from the existing sources.

This would bring the farm a step closer to being off-grid in terms of importing energy and water, helping to fix costs on most of the things that the farm needs every day. It would also improve the slurry, as digestate has more available nutrients than separated slurry, which theoretically should reduce the farm’s fertiliser costs, too.

Monitoring

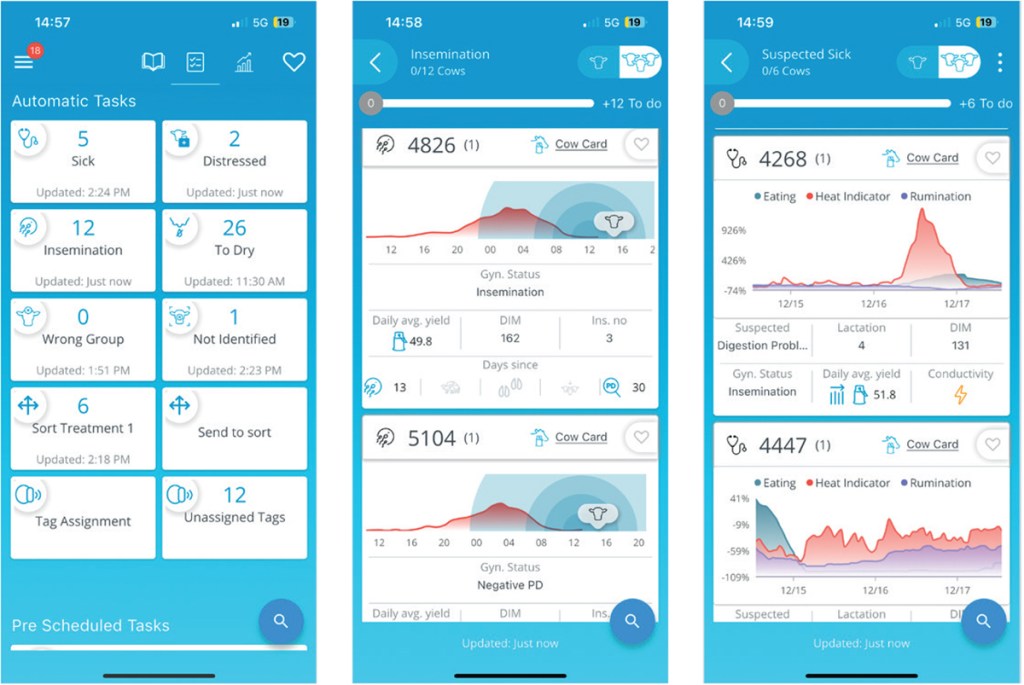

Two years ago the farm decided on the AfiMilk system, and it has gone down very well.

Like many systems it’s based around a collar to gather cow statistics, with eating time and movement being key, AfiMilk also learns from the cows as individuals and as a group to understand their eating and rumination patterns.

“We like the system. The heat cycle alerts have proven effective, we’re seeing better insemination results and are picking up sick cows sooner, so the recovery time is faster, and the herd health is better.” Ed explained.

Summary

T H Flower is a forward-thinking family farm. It has grown its business by improving the welfare of the dairy herd, to achieve a high average yield. The 1% theory can be seen to work in practice, all while being a thousand feet up in the Peak District and not following the trend of simply adding more heads to pump out more litres.

Ken Topham

For more up-to-date farming news click here and subscribe now to profi and save.