While it has diversified into mowers, bale wrappers remain the bread and butter business for Tanco. In its line-up are the mounted Q models, which can be used with both square and round bales. But is this versatility compromised? We try out the twin-dispenser Q200-V to find out.

KEEPING IT BRIEF

- Tanco launched the Q-series in 202?

- Can be rear- or front-tractor mounted or used on a front loader or with a handler.

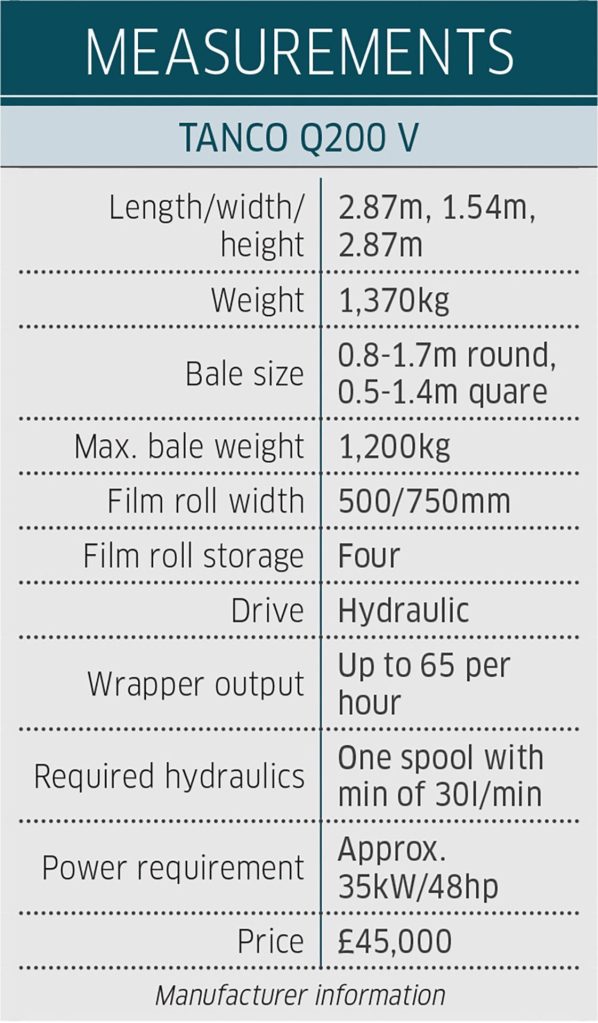

- Price for the tested Q200-V is £45,000

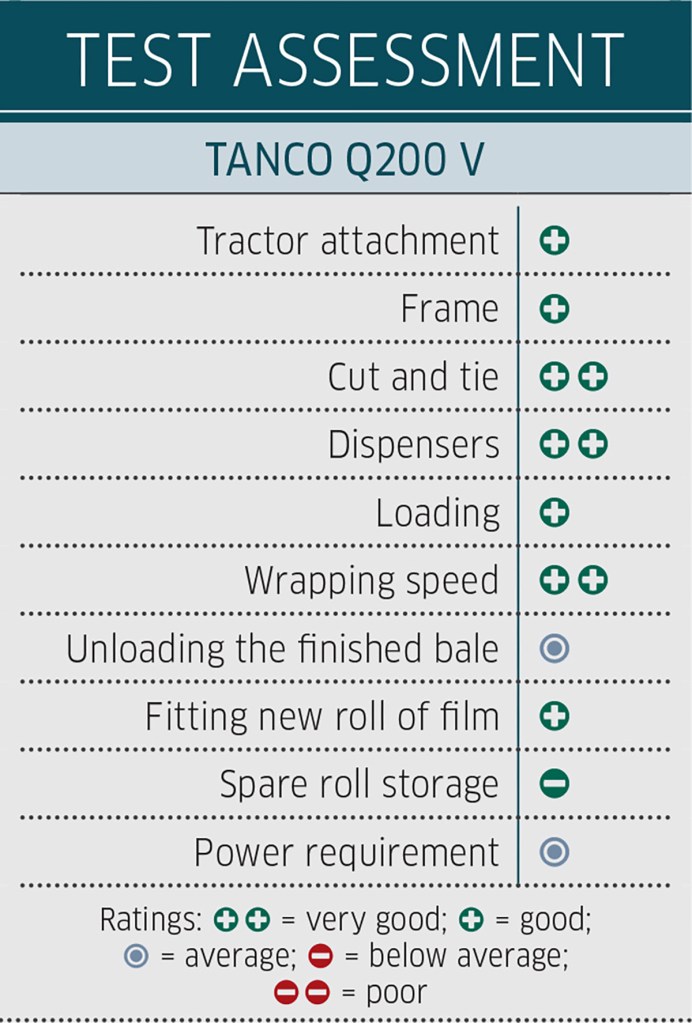

After analysing operator feedback and building on its proven 1540 EH model, Tanco has produced the Q200-V bale wrapper, sporting advanced levels of automation for reduced user fatigue. Also notable are the lengthened cradle rollers, providing more support to the bale during wrapping. Indeed, one of the Tanco’s selling points is its ability to utilise those rollers to pick up and wrap anything from single 50x80cm bales to 140x120cm twin-packs.

I, however, couldn’t provide anything quite so exotic to test but can well believe the Tanco claims after using a test machine this summer on a diet of 90x80cm squares with a few 120cm diameter rounds thrown in for variety — yes, the Q200 can also package round bales up to 1.7m in diameter.

Getting hitched

Sat there in its fetching yellow and grey livery, it was only as I reversed the tractor up to attach the machine that I was struck by just how compact it is. Hooking up was simplified by smart colour-coded ends on the hydraulic pipes and a beefy, clutter-free headstock. This particular machine came specced for a load-sensing hydraulic supply, but conventional flow and return systems are optional. A stand-alone circuit used to alter the bed width comes with a welcome spool valve positioned down on the machine, aiding the removal and refitting of the pins. Minimum flow requirement is 30l/min, but 60l/min is optimal.

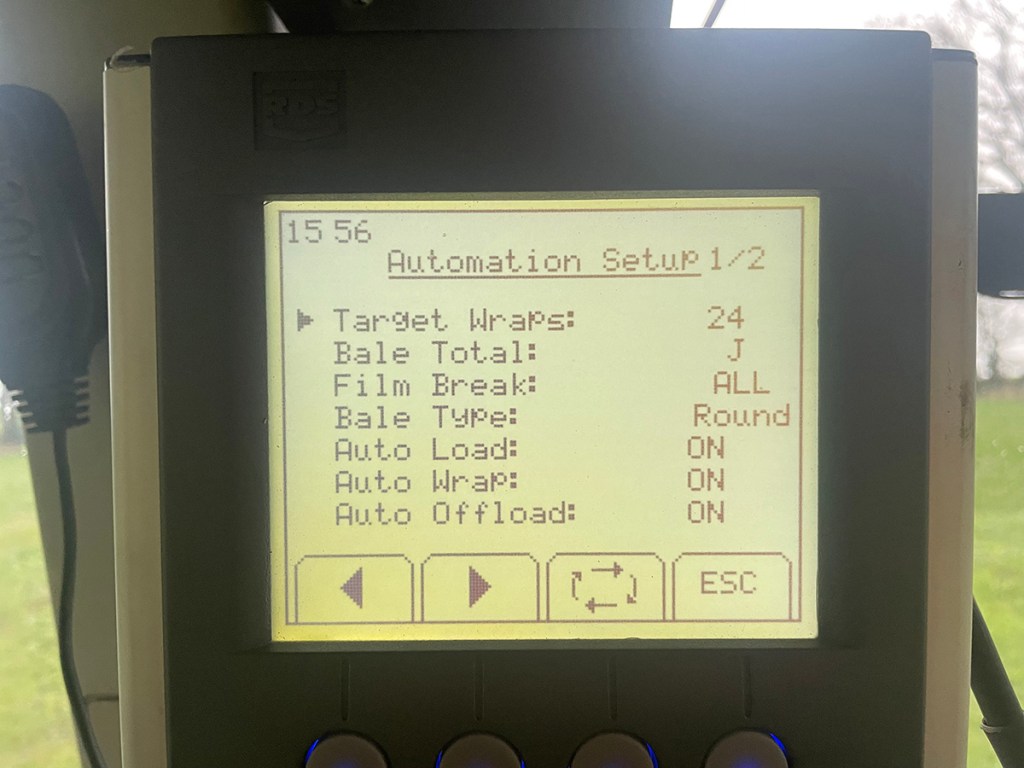

The RDS-supplied Expert Plus Controller is bestowed with easy-to-follow menus and comes pre-loaded with parameters for many bale sizes and shapes. Simply cross reference the bale size and required layers of film in the handbook to find the recommended turns needed. For the niftiest of pickers, calibration using your specific bales can be performed, with fine tuning of all parameters still possible through an advanced set-up menu.

Good, now we are all hooked up, it’s time to hit the wrapping road. Compared to my own Kverneland 7655 with its rather troublesome transport width of 3.0m, the Tanco Q comes in at 1.54m, a little over half that. Besides watching for a little tail swing, these tight dimensions meant no gateway or lane was now off limits. However, weighing in at 1,370kg, with a max bale weight of 1200kg, a counterweight is advisable for stability on and off road. For reference, a foreloader and wrap carrier felt ample to steady the ship, but the return journey home, devoid of the 300kgs of wrap, did seem less stable.

Once safely in the field the levels of wrap automation can be set to the point where no button pressing is needed, bale after bale. Auto load comes courtesy of a sensor and robust rubber-cushioned bump stop. Just reverse over the bale, make contact and wait for the confirmation beep.

The wrap cycle then starts with the Q200’s main party piece — up until this point, both of the satellites have been snugly tucked up together, next to the headstock and safely away from the entering bale. The foremost satellite swings through pretty much 180⁰ to oppose its fixed counterpart; then they both rotate in the conventional manner.

During the slowdown cycle of the last lap, the movable satellite is slickly drawn back beside the other, allowing both tails of wrap to be caught and cut by the one mechanism. Knowing how infuriating a temperamental cut-and-hold mechanism can be, I am happy to report the Tanco’s was faultless.

Bale drop

Rounding out the wrap sequence, the Tanco has a neat feature where rectangular section bales are returned to flat ensuring there’s a controlled release. Naturally, a beep warns of the approaching bale drop, but, due partly to the rapid wrap sequence, I was caught napping more than once when manoeuvring only to see a bale released in an unhelpful spot. Again, my fault, but once a machine is set up and working well I am a little reluctant to alter it and would much rather adapt my technique. A steady forward pace at drop-off is recommended, as the dropped bale could, and did, get detected by the auto load and wrapped again. This tends to be a rite of passage that all novice operators experience, but generally only once.

All good, then. A compact and quick machine capable of wrapping almost anything you can drive it over, automatically.

Not quite. There are always trade-offs. The increased manoeuvrability provided by a mounted machine comes at the price of your ground clearance being dictated by the pitch of the tractor. The front wheels did not need to rise much before the lower cradle rollers touched the ground, especially when loading/ unloading. A headstock-mounted roller helps to carry weight and accommodate terrain but, working in hilly areas, I found myself running the machine clear of the ground, only lowering for loading and unloading. Thanks to the robust build quality, I doubt any harm would befall the machine chassis should it catch the ground.

Developing a height-sensing radar to control the tractor linkage, or a hydraulic top link, would be perhaps overkill, but some kind of warning buzzer would be appreciated, as you simply can’t see the lower rollers in use.

Working on slopes

When wrapping on a slope I would advise against using the plate at the front of the bed as a buffer to stop the bales creeping forward as they roll. Come drop off, the rear of the bale falls normally, but the front can ‘hang’, leading to the bale flopping forwards and onto the auto load sensor bar. On more than one occasion this damaged the wrap, necessitating a re-wrap. However, pictures on the manufacturer’s own website show a more rounded sensor bar, perhaps indicating the issue has already been addressed.

Due to the mounted nature, and needing to shuttle on and off bales, the levels of neck craning required were far higher than when using an offset trailed machine. Should this be a real problem, there’s always the option to mount on the front of a tractor or even a suitably sized telehandler, with kits available from Tanco to extend the wiring.

If ultimate performance is your thing, then you could always consider the Q200’s bigger brother, the Q300 model, which sports an impressive three satellites for faster wrap application. This, I thought, should be more than enough capacity to satisfy anyone, yet the company’s Michael Dollard informed me that some customers were operating two machines on the one tractor, fore and aft, and achieving spot work rates in the region of 120 bales per hour.

Summary

Compact and capable would be an honest assessment. Drawing comparisons with an ageing trailed machine perhaps is unfair, but it definitely highlighted the continued issues of running a 3m wide machine in an area full of small roads and 10ft gateways. The capability to wrap just about anything under 1.5m wide, regardless of its shape, should appeal to any users running multiple balers, especially the equestrian’s favourite 50 x 80cm pack.

As mentioned, my biggest issue with the machine was ground clearance in rougher fields — a symptom of my local topography as much as of machine design.

Ultimately, the key question is: “Will it be missed?”. Yes, as I could see years’ worth of faithful service thanks to solid build quality and excellent company back-up. Should you wish to purchase a Q200-V wrapper, on-farm prices start at £35k.

Nigel Thornborrow

For more up-to-date farming news click here and subscribe now to profi and save.