Adapting crop storage to meet the changing needs of the modern farm can be a challenge and can require significant investment. A new grain dryer and handling system has allowed Temple Farming Partnership in Wiltshire to utilise upgraded existing buildings and has facilitated phased development.

KEEPING IT BRIEF

- New grain system makes use of existing buildings.

- A Mecmar mobile dryer is fed via the new intake and discharges dried grain into the back of the shed..

- A modular grain elevator system can be expanded to the second building ; the control system is also configured for this.

With a history as significant arable enterprise in the 1980s, the Temple Farming Partnership estate, near Marlborough, has recently changed hands, explains farm manager Ivo Yates: “The land was contract farmed for 10-12 years and the buildings were rented out for non-farming use. When the arable enterprise was taken back in house two years ago there was no suitable grain storage. There was a 40t/hr Svegma tower dryer that had been installed in 2005 but it was too big for our needs, and much of the handling system had been sold off,” he says.

One option was to build new stores and keep the existing buildings for commercial use; using outside storage was also considered.

“We were having to sell grain straight away, but our experience was that it was difficult to get lorries at the peak time. Even if we bought in storage off-farm, that didn’t get over the problem of storing immediately after harvest.

“The cost of building new stores was a major factor in our considerations; the existing buildings needed work to remove asbestos regardless of their future use. We felt that by upgrading them, we had a ‘what if’ plan where they could easily be returned to commercial use if necessary.”

Grain and grass

With rotational grass now part of the enterprise, Temple Farming Partnership crops 340ha and needs around 2,000 tonnes of storage. It’s also a business that is demanding on staff time with 850 breeding ewes and 50 suckler cows to care for.

“It’s not large-scale grain storage; we need the solution to offer easy operation by our two-man team and to be affordable. We looked at refurbishing the existing dryer but thought it was better to start from scratch.”

With the farm moving to low input regenerative practices, including livestock and lower fungicide and nitrogen use, the ability to handle a wider range of crops is also significant. McArthur BDC was approached with the wish list for the new drying and handling development.

“We require a dryer that is as automated as possible and can ‘look after itself’ for long periods without being manned,” says Ivo.

It also needs to fit in with harvest arrangements: Temple Farming Partnership utilises a contractor for combining who uses a New Holland CR90.90 with a 10.6m (35ft) header, which can see 350-400 tonnes arrive in the yard each day.

“They can easily cut 35-40ha a day as they are big fields and we’re ring fenced so there’s not much travel,” explains the farm manager.

What was installed

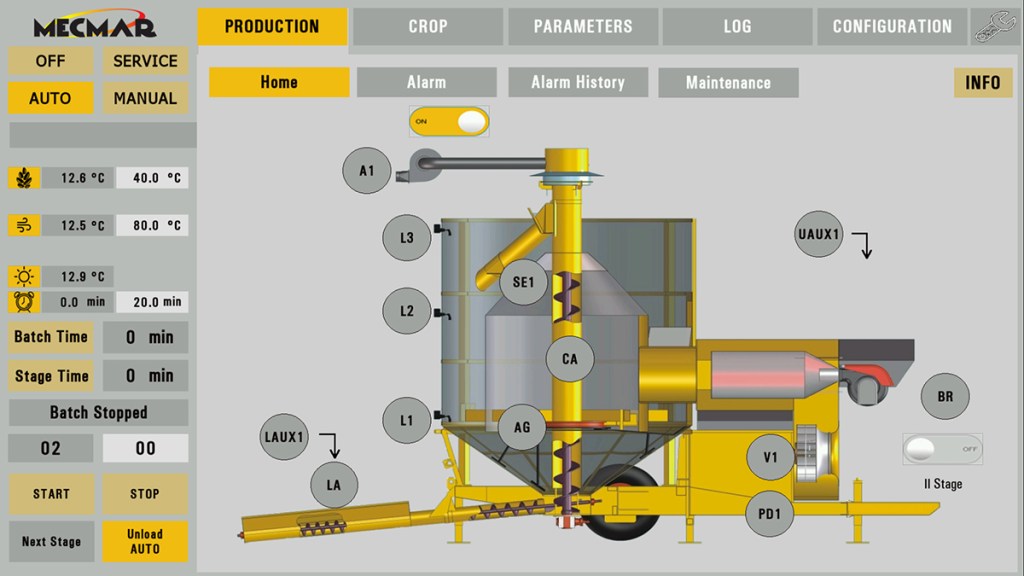

After a site visit and discussions with the Temple Farming Partnership team, McArthur BDC’s Andrew Lee recommended a Mecmar D24 T (24 tonne capacity) electric fully automatic dryer. It is fed via a Skandia chain and flight curved intake trench conveyor installed underground with pre-cast sections to form the trench and a drive over grid for unloading. The removal of the old dryer has allowed the installation of a large concrete pad alongside the store.

“This means we can start combining early if necessary and take wet grain into the dryer through the day while the rest is tipped, or stockpile grain if the weather comes wet and then dry it,” Ivo explains. “Taking 3.0 per cent out of wheat from 18% to 15%, including cooling time, each 24 tonne batch takes around three and a half hours from loading to emptying. A stand-alone cooling and conditioning process with spring barley takes around an hour and a half. Once the dryer is set and going it is all automated and monitored via a phone app.”

This app connects with the touchscreen PLC panel on the dryer, allowing Ivo to tweak settings remotely and also receive status updates and any alerts. The screen also displays maintenance schedules which can be accessed via the app.

The dryer is fitted with an aspirator to clean the crop as it dries it, and Ivo comments that this suits the farm’s cropping.

“We’re two thirds spring crops – mainly spring barley, spring oats and peas – and wheat is our only winter crop. Peas are grown for premium so need to be a green colour, which means that often we have to dry them well and look after them,” notes he farmer.

The system is also used to condition and cool spring barley; Ivo points out that screenings were universally high in the 2025 season, yet his samples have been good quality. The aspirator feeds screenings to a cyclone on the side of the first store where they are deposited into a trailer.

“A cereal screen has worked well on peas,” comments Ivo. “As the grain comes out of the dryer’s auger the aspirator takes the ‘lights’ off and it has worked well on chaff and debris. We also like how the action of the auger polishes and cleans the grain. It’s obviously not as good as a stand-alone cleaner but better than a drying floor.”

The dryer itself activates the operation of the Skandia Elevator KTA60 with 60t/hr chain and flight conveyors taking grain into the shed. A Skandia Elevator horizontal chain and flight conveyor with multiple outlets then feeds the store.

The two buildings, which were reclad by a local firm in 2024, are split into four bays. Currently the elevators feed the first building with the option to extend to the second in the future and link into the control system.

“We’re moving the grain between the stores with a loader at the moment; one bay next to the dryer is kept empty for it to discharge into, but in the 2025 harvest most went straight into the store.”

The layout of the site was reversed compared to the previous system, Andrew comments: “We switched the dryer intake around so that the crop comes in from the rear of the building; grain then fills from the rear to the front of the shed, which is best for the chain and flight system. This layout also offered up the extra space for tipping grain at the front of the building.”

How has it performed?

In its first season of use, Ivo suggests that the dryer has proved efficient – McArthur BDC’s figures put fuel usage at 1.0-1.2 litres of diesel for each percentage of moisture extracted per tonne, based on drying feed wheat with an air temperature of 120˚C.

A temperature differential control system has also been supplied by McArthur, controlling aeration fans that are cooling and conditioning the grain using a grain temperature probe and an ambient air temperature sensor.

When there is a differential of 3.0-5.0˚ (set by the operator) it will turn the fan on because the ambient air is cooler than the grain, therefore having a cooling effect. As soon as the air temperature goes up it turns the fan off.

“This uses less energy and takes less time to cool the grain, as we’re using the optimum air temperature,” explains Andrew.

Ivo adds, “We went for a simple fan system using four Polycool pedestals per shed. Louvres will be added in phase three of the development.”

Work started with recladding the sheds in 2024, the dryer was ordered in March 2025, delivered in May and commissioned in June.

A development including new buildings would have come in a around £1.5million, whereas the final project costs were £400,000 to £450,000.

Carrying out a lot of the groundworks in house and subbing in their own electricians helped the farm keep control of the final figures.

“We now have 2000 tonnes of storage and a dryer that should last 20 years or more, and the automation really suits our workload,” points out Ivo. “It was hard to find a company to design and specify the system that would understand what the farmer actually wants, but McArthur BDC has worked closely with us to meet our needs.”

The system is also flexible, he points out – it has spare capacity if needed but would also be easy to dismantle and sell the dryer and conveyors if the business has a change of direction.

Jane Carley

For more up-to-date farming news click here and subscribe now to profi and save.