Looking for a trailed diet feeder? We’re focusing on machines in the twin auger, 22-24m3 category and the various options available.

W

hile the number of dairy herds in the UK is undoubtedly on the decline, herd sizes continue to grow, the national average being 200 cows. Twin auger feeders are becoming the machine of choice for this size of herd, commonly from 20m3 upwards.

Dave Perry, Siloking product specialist for Kverneland, suggests that twin auger machines are capable of feeding anything from 200 to 1,500 cows depending on the size of machine and farm layout and that while self-propelled machines are increasing in popularity, trailed machines still far outweigh them in the market.

Dean Cottey, Strautmann product specialist at Opico, comments that demand remains healthy in general, as it’s a machine that farmers depend on day in and day out, so is more likely to be replaced regularly than seasonally-used equipment.

“The ability to mix a range of ingredients efficiently and the use of hardwearing components are priorities for most customers,” confirms Dave Perry.

Dean Cottey suggests that simplicity is a winner when it comes to the machines themselves, with simple door discharge systems using less components and at lower risk of damage.

“When new sheds are built, the requirement is often for ‘on floor’ feeding which avoids having to clean out troughs, so there’s no need for a conveyor system to feed over barriers.”

Durability is another priority, suggests Kuhn product specialist Rhodri Jenkins, with hard facings such as Kuhn’s K-NOX a popular option to protect augers and knives.

“Our trials showed that after 7,000hrs, a standard 15mm thick auger was reduced to 7mm, whereas with K-NOX facing it was still 13mm thick after the same workload.”

Lining the lower part of the tub walls is another option, commonly a retro fit refurb on older machines rather than from new.

Jane Carley

For more up-to-date farming news click here and subscribe now to profi and save.

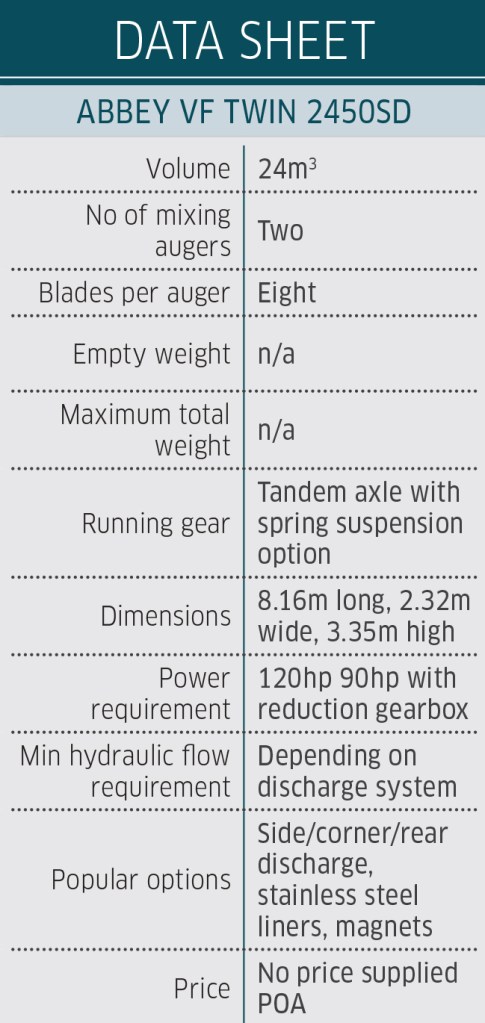

ABBEY

Abbey’s Plus Range VF2450 has a 50% thicker auger for extended working, and the wider base coupled with improved gearbox mounting flange are designed to enhance better mixing performance. Door design delivers improved flow of material positioning the feed to centre of the door as it exits the feeder for a more even and rapid feed-out. The EZ2810 system indicator is available on all feeders and can link to feed apps for added versatility. A parallel top retaining ring reduces any feed waste during mixing.

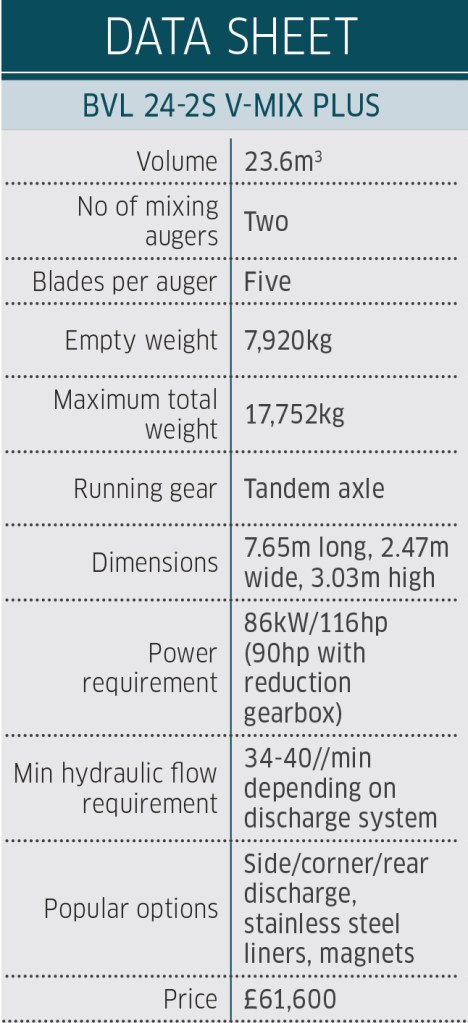

BVL

The BvL Hardox steel mixing auger has outwardly ascending flights, to centre the flow of the feed in the mixing hopper.

Asymmetric arrangement of the rotors inside the hopper is designed to improve the flow of feed between them, giving quicker exchange between the chambers for high mixing speeds.

The patented EDS system, which has the 1,100mm wide doors placed in an asymmetrical arrangement towards the machine’s centre, is designed to easily push the feed out without interrupting its flow.

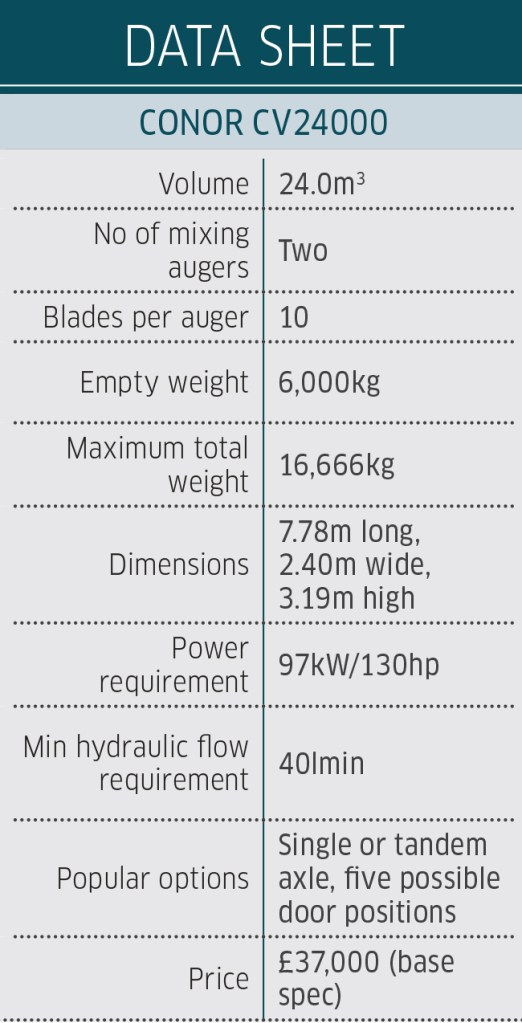

CONOR ENGINEERING

The CB24000 is the flagship model in Conor’s single and twin rotor range, with discharge doors positioned at the corners, on the trajectory of the augers rather than on the side. It features an independent reinforced chassis for stability and slim drawbar for easier manoeuvring in traditional buildings. Hardox flights option. Standard spec is twin feed-out doors, but recent updates include options of a fully sealed rubber belt conveyor and slide and tilt conveyor with HD rubber belt.

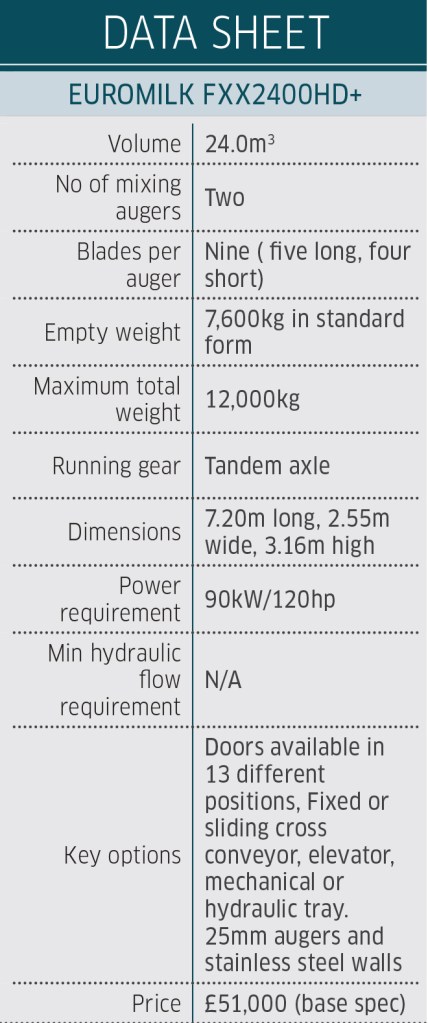

EUROMILK

Supplied in the UK by HF Evans, the Polish-made Euromilk Rino FXX 2400HD+ comes at the lower end of a range that extends to 32m3. Key features include a reinforced frame structure, a wide hopper, 20mm thick augers and floor, plus 8mm walls and inspection ports at the front of the hopper. Optionally, the machine can be equipped with a steering axle with a reverse lock.

Control is direct to the tractor or via an electric wired control box or wireless remote control. A powershift transmission allows the operator to change speed from the cab without disengaging the tractor’s pto when the drive is under load, saving time and reducing wear and tear. App controllers for smart devices can also be specified.

HI-SPEC

The company has designed its augers to help the feed move in a figure eight motion, using vertical and horizontal movement and lifting the feed from the floor.

T series machines have vertical reinforcement to the underside of their 20mm thick floors; a two-speed gearbox is standard.

Hi-Spec feeders now feature a newly designed vertical feeder body with the upper taper now removed and replaced with a bolt on upper section. This will make it possible for a customer to modify a T20 to a T24 at a future date should they wish by bolting on new increased height upper sections. The ladder is also being updated to a platform type to give a more stable base to view a mix.

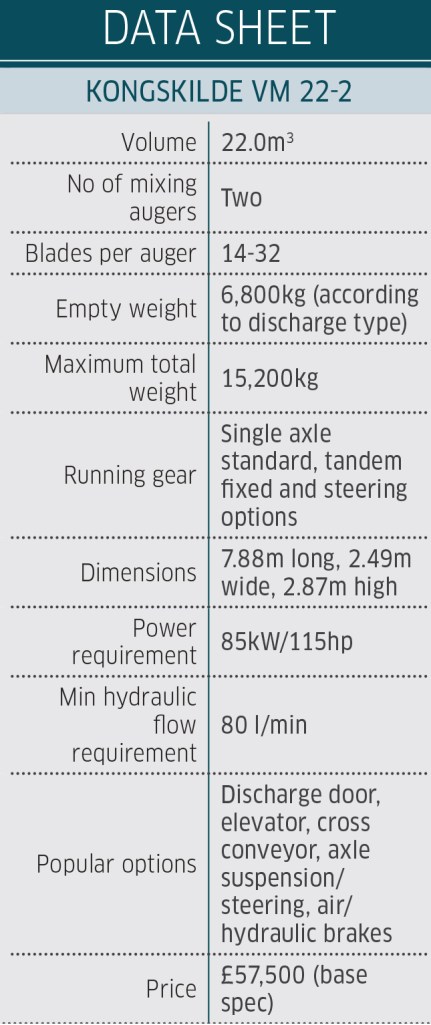

KONGSKILDE

Following the sale of the Kongskilde product range by CNH to Italian firm Seko Industries, Kongskilde VM vertical auger complete diet mixers are now available in Great Britain through a new distribution agreement with Huntingdon-based ASC Autonomy. Production has been relocated to the Seko facility in northern Italy, which already produces Seko-branded vertical mixer wagons.

The VM machines retain the Kongskilde brand and colours but benefit from improvements including a redesigned tub with reshaped bow and stern that aids material retention for enhanced processing and mixing. Further upgrades include improved axles with optional suspension and steering option, and hydraulic or air braking availability.

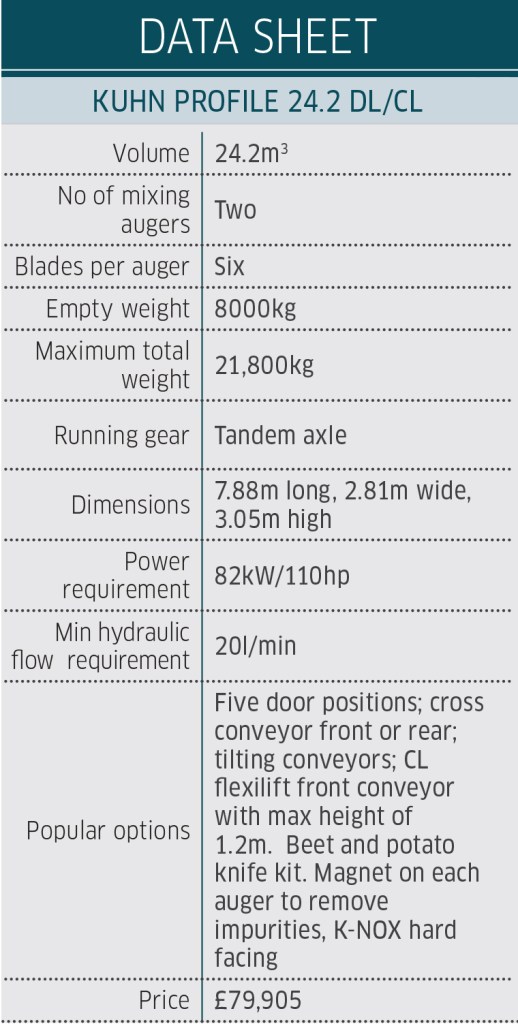

KUHN

Kuhn says that the 24.2 model is one of most popular choices in its Profile 2 range from 18m3 up to 34m3. All models in the UK over 18m3 are fitted with tandem axles.

K-NOX alloy coating containing chrome ferrites improving wear resistance to acidic material and friction can be specified for the augers, said to offer six times the life of standard augers.

A two-speed gearbox is a popular option, 16rpm requiring 7hp/t to run and 29rpm requiring 13hp/t to run. Benefits are the ability to run the same high output mixer on a sub-100hp tractor at the lower speed.

The lower speed useful when starting tub full – more forgiving on the driveline and can improve component longevity.

An electric changeover option between the two speeds using additional control box is a further option.

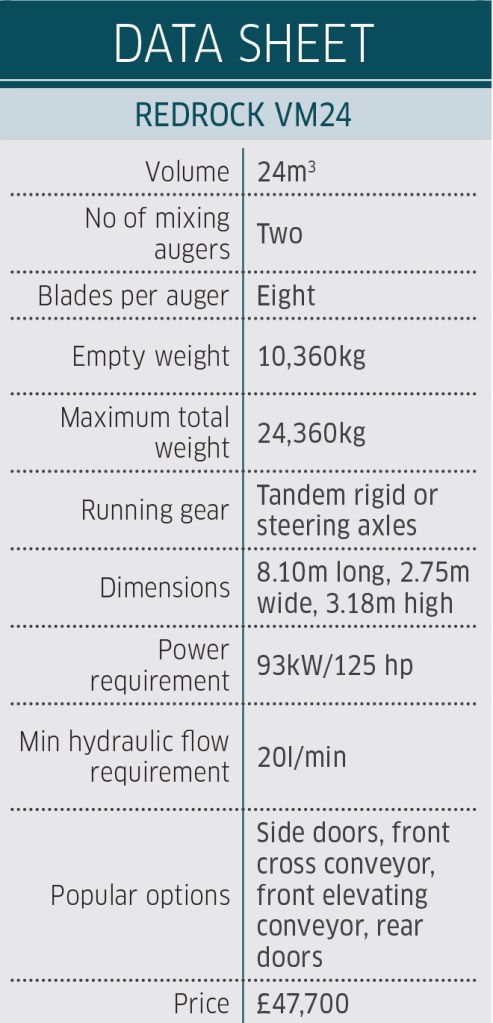

REDROCK

Redrock VM Twin Auger feeders include machines from 15m³ to 28m³ with larger capacities available on request. Large discharge doors which allow consistent discharge and more efficient chopping between augers.

The VM feeder range uses serrated knives, assisted by two counter knives which restrict the material as it is driven past them by the auger to chop fibrous foodstuffs to the length required. The auger incorporates a carefully positioned sweeper arm to help blend ingredients. A two-speed drive line planetary system is used to reduce horsepower requirement.

Specification includes a wide angled pto with shear bolt protection, hydraulic brakes, LED lights and a viewing ladder/platform.

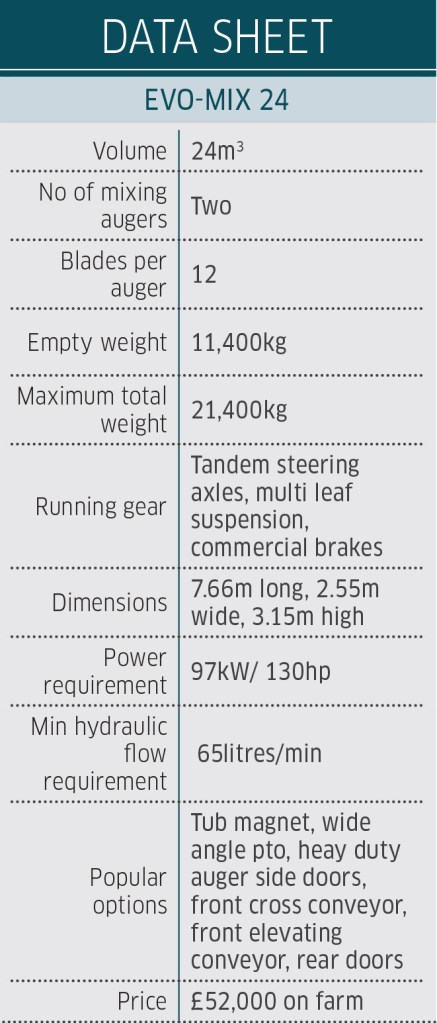

RS AGRI

Designed in the UK, the RS Agri EVO-MIX was specifically developed for the requirements of UK farmers. It has full width and optimum height augers to ensure the material is brought higher up the tub, plus a cross-over auger system, giving a more homogenous mix and reducing.

A two-speed gearbox with in-cab hydraulic gear change is fitted as standard, and all machines have a separate chassis to absorb forces and stresses from the ground, keeping them from being transferred to the mixing tub and increasing weighing accuracy and reliability

Construction is of 316 stainless steel said to offer greater wear, corrosion, acid and abrasion resistance, than steel alloy. thus increasing the life of the machine.

SHELBOURNE REYNOLDS

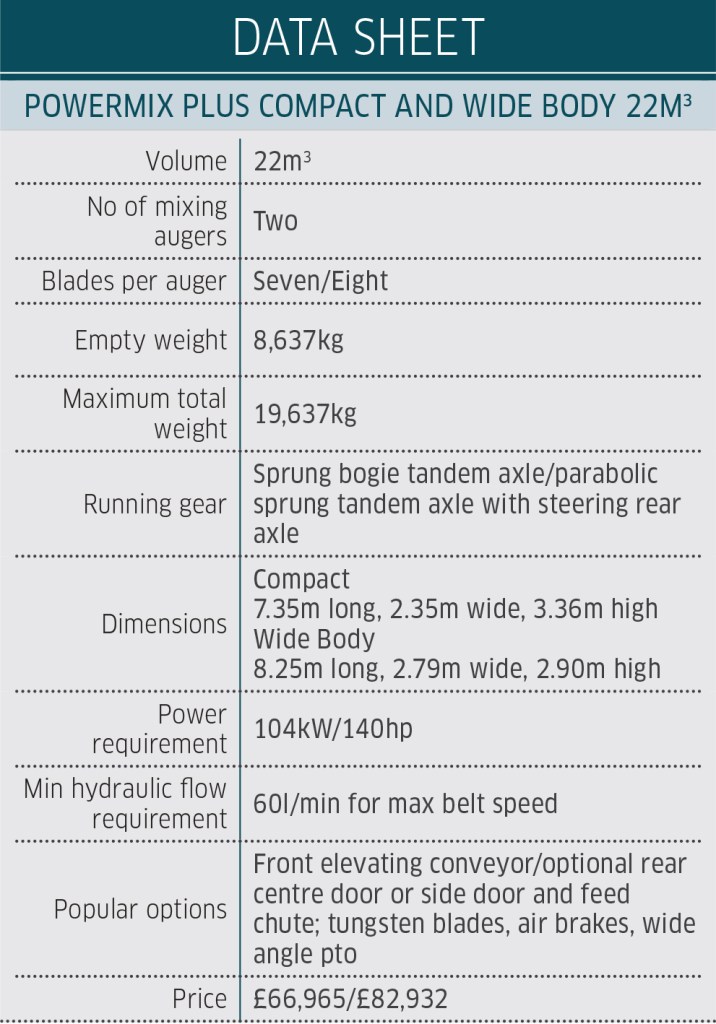

Shelbourne Reynolds’ Powermix range of vertical diet feeders includes two models in the 22m3 size, featuring a curved tub designed to speed up bale processing and mixing and said to be capable of mixing at least 10 tonnes of feed per batch, depending on dry matter.

The Powermix Plus Compact 22m3, at 3,365mm high and 2,350mm wide is relatively narrow which helps when navigating around older buildings. It is available in a tandem axle configuration.

The Powermix Plus Wide Body 22m3 measures 2,900mm high and 2,790mm wide. While the wider tub achieves capacity, its reduced height makes it suited to buildings with limited access.

All Shelbourne mixer wagons feature a front mounted webbing conveyor capable of elevating feed up to 1.5m to either side of the machine and returning to a central position within the width of the tub. Side door models are also available.

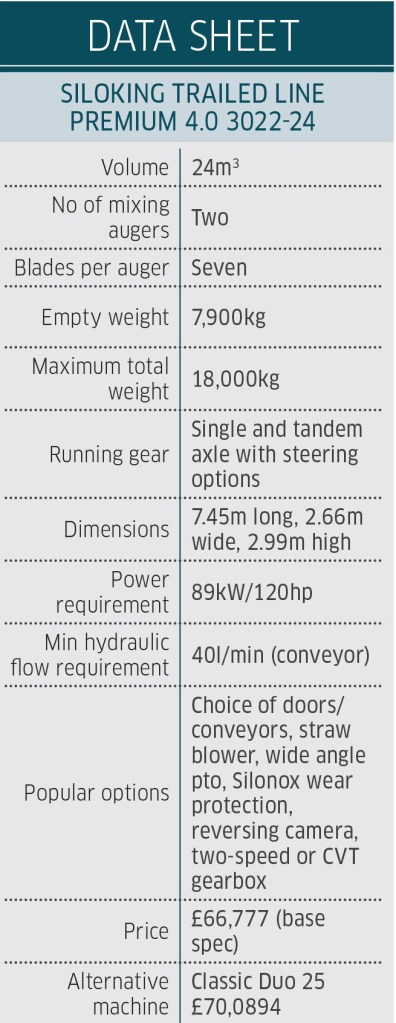

SILOKING (Supplied by Kverneland UK)

A number of updates have been made to the 4.0 ranges which include 24m3 models. Augers are faced with Silonox hard wearing coating as standard and a new design magnet comes with a tool to remove its cover for cleaning, avoiding the need to climb into the tub. Adjustable blades can now be moved sideways as well as up and down, allowing the blade to be moved back out the side of the tub as it wears.

Siloking Variospeed uses a CVT gearbox in place of the two-speed gearbox on the front of the machine. It has three speed ranges (mixing 15-25 rpm, cutting 23-44rpm and residual emptying 50-55rpm), changeable during the mixing/emptying process without disengaging the pto. Mixing speeds and times can be allocated to each ingredient in the loading programme via the data system – for example to increase auger speed to chop straw for dry cows, reducing again automatically to add the blends. Variospeed speeds up the feeding cycle times by changing speed automatically through the data system but also reducing emptying times.

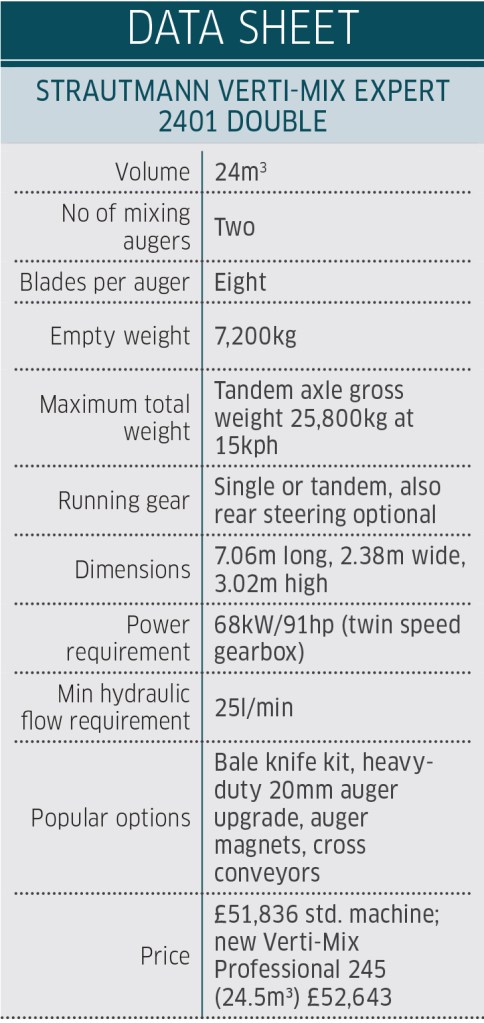

STRAUTMANN (Supplied by Opico in the UK)

Strautmann has recently launched the ‘Professional’ range, a simplified version of its Verti-Mix feeder wagons within a more compact chassis.

This range retains Strautmann’s IMS vertical augers from the Expert feeders, which feature stepped auger flights said to offer faster, more even mixing across a range of rations.

The shortened chassis and drawbar plus reconfigured driveline guarding has made it possible to shorten the distance between the towing eye and the mixing tub, making for a much more compact machine overall, suitable for smaller yards and difficult to access buildings.

Alongside the shortened chassis, there is a simpler three-point weighing system. Side doors are 100mm wider, designed to make for rapid feed-outs and there is the option of a rear cross conveyor or Danish rear doors.

Extensions are available to increase the capacity of the Verti-Mix feeders, allowing a business to ‘futureproof’ by purchasing the size of feeder for the herd they have now, with the option to extend as more stock are added – for example a 19m3 tub can be extended to 24m3.

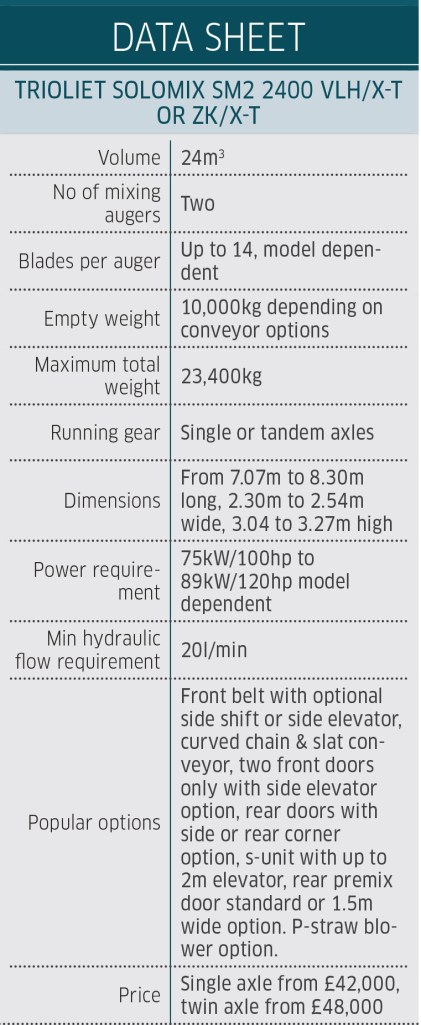

TRIOLIET

Solomix 2 feeders are available in a variety of models with different discharge configurations, build specification and overall dimensions.

All use the ‘Dual Flow’ system: vertical flow where where the feed is pushed up due to the shape of the Twin Stream mixing augers and falls back down again; horizontal flow via patented asymmetrical triangular inserts in the tub to ensure that the feed is being transported through the entire mixing vessel for an even mix. Large doors and double auger wings on the augers are designed to offer a smooth discharge.

Trioliet’s two- or three-speed automatic Shift-tronic gearboxes now also come with App control for easier operation.

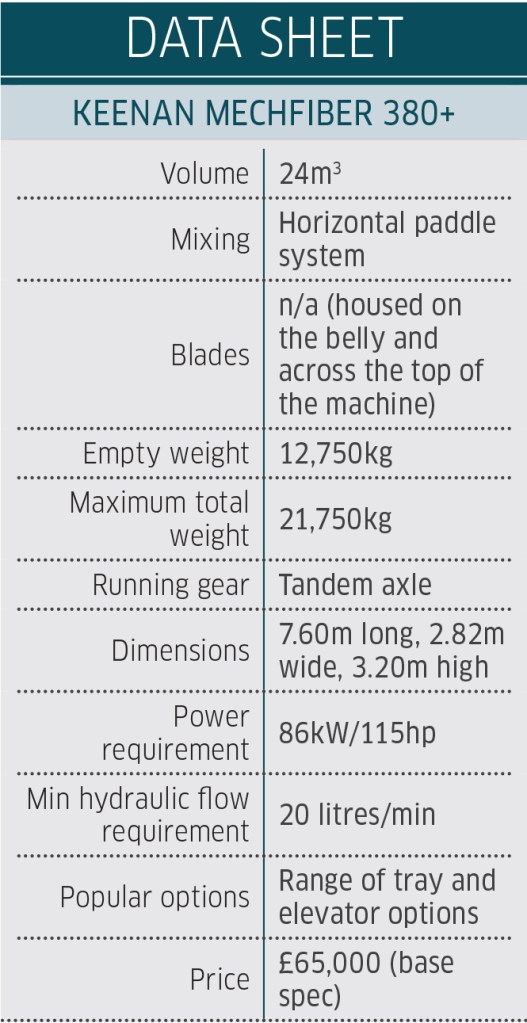

KEENAN

Keenan’s focus here is the horizontal paddle machine. The MechFiber 380+ uses a horizontal paddle system and has seen a number of updates. The ‘castellations’ on the paddle reel have been re-engineered to give a rounded top section alongside an increased rake angle, allowing for greater material movement in the chamber. Less material now resides on the paddles, meaning better mixing with less friction and wear on the machine.

An automatic oiling system operated by the hydraulic rams opening and closing the guillotine door can be fitted to deliver ‘pulses’ of oil to the drive chains, lubricating them to the optimum levels for safety and improved chain life.

A 40% longer feed-out door offers a faster feed-out time. Housed in specially moulded durable black pods, lights have been added to the feed-out door for better visibility when ambient lighting is low.

The control unit is mounted and hardwired to the weigh cells on the diet feeder for improved weighing-in accuracy and live transfer of loading weight onto the operator’s display screen. The fourth generation displays the status of machine oil levels, temperature, chain tension, and feed-out door.

WEIGHING IN

Accurate weighing is key to the feeding operation, from efficient mixing of the ration to providing groups of cows with the right amount of ingredients.

Weighing bars/cells are fitted to the chassis of the machine to calculate the weight of ingredients as they are loaded and linked to the controller in the tractor cab. More weigh cells can increase the accuracy (Kuhn claims 99% for its five-cell system) with its but also add to the size and complexity of the feeder. Strautmann has reflected this with its new compact Pro range which uses three weigh cells.

At the most basic level, this weight is shown on a digital display. This offers ‘recipes’ for different mixes which can be factory settings or programmable by the user. Systems from Dynamica Generale are widely used for this; Redrock, RS Agri and Trioliet are among the manufacturers that opt for Topcon equivalents.

Programmable systems allow changes to be made to the feed amount in each mix based on the number of cows in herd, for example to take account of cows being dried off.

A second terminal can be fitted to the loading vehicle, connected to the tractor via radio signal or wifi; this may also be able to control the electro-hydraulic functions of the feeder. Manufacturers including Siloking and Trioliet also offer control of the weighing system via a smart phone or tablet.

Kongskilde has recently updated its control system offering wireless controllers for both mixer tractor and loader. Handheld wireless controllers are another option.

Kuhn’s Rhodri Jenkins comments that the secondary display system is a popular option for its machines, allowing the loader driver to control the operation.

Cloud-based feed management systems connect the herd manager with the weighing system allowing recipes, feed components, animal groups and unloading points to be created remotely, along with nominal/actual comparison and adaption of dry matter. Reports and analysis of feeding accuracy, times, feed costs, contribution margin (IOFC) and feeding efficiency (CFE) can be obtained via the system.

Feed management and control apps are also available from many manufacturers, giving real time connection to the weighing system on the feed mixer and the feed management software.

Technology can also be used to maximise feed value: Siloking product manager Dave Perry reports interest in the using ration programming to adjust the mixture based on dry matter levels at the pit face, given the shortage of grass this season.

However, manufacturers report that take-up of high tech solutions is restricted to larger herds; manual ration inputting remains the most popular choice.

“Data recording is useful where a farm has several drivers operating the feeder, and bonuses are paid for loading accuracy. A driver profile is created in the terminal and the date, time and driver are uploaded to the cloud. It’s a subscription-free service from Siloking and can improve the ability to control feeding costs,” says Dave Perry.