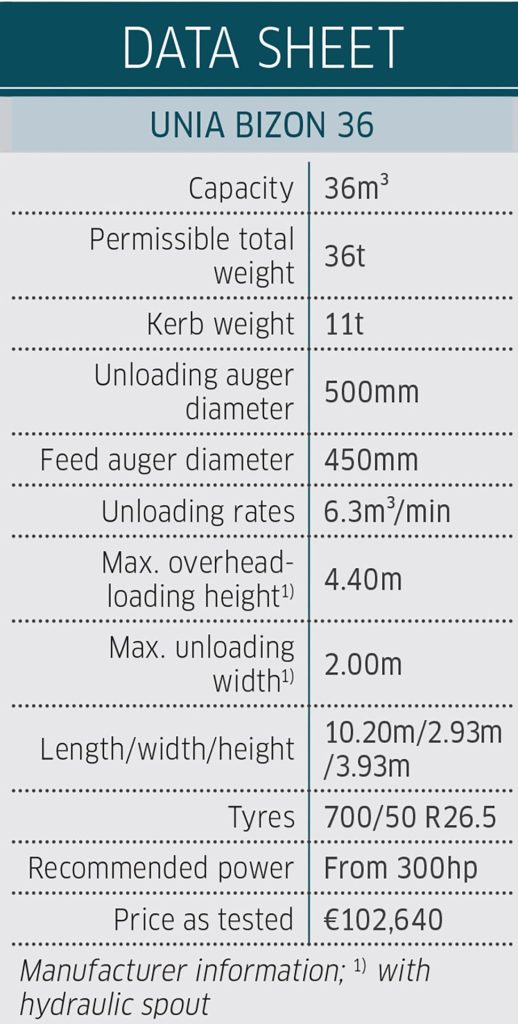

Unia is one of the largest farm machinery makers in Poland, offering a hugely diverse line-up of kit including a range of chaser bins. The Bizon 36 is the biggest bin in the Unia family with a capacity in the region of 27t.

KEEPING IT BRIEF

- Unia’s Bizon 36 holds 27t of wheat and unloads at a rate of 1.4t/sec.

- Three augers are tasked with emptying the trailer.

- The entry-level version carries a price of €95,440.

Filling a truck in one go takes a really big chaser bin, one like the tri-axle Bizon 36, the name giving more than a hint of its 36m³ capacity.

Five spools required

Unia’s big bin doesn’t have its own on-board hydraulics; instead it relies on the tractor having five spool valves — a single-acting valve for the parking stand and four double-acters for the steering axles, folding the unloading auger, auger clutch engagement and pivoting the spout. A diverter valve can redirect the oil flow to opening the doors for cleaning out the bin.

Other bits attached to the tractor’s back-end include the La Magdalena pto shaft, the main lights and the plug for the optional Dinamica Generale sourced weighing system. Rather than use one long shaft between the tractor and auger gearbox, it splits into two shorter shafts, with a carrier mounted on the drawbar to overcome the angle of the low-slung gearbox.

The base model has parabolic spring suspension with steered front and rear axles. The total road-going weight of the big Bizon is 31t, which translates to a payload in the region of 20t. In the field, this increases up to 36t, and once filled to capacity we were able to get 27t or so of wheat into it when on test.

Three augers

Three augers ensure the crop flows steadily from the hopper: two 450mm augers in the bin bottom move the material forwards to the unloading auger so that when the driver engages the bin’s pto, the directly driven unloading auger immediately starts to run and churn out the contents.

A shear bolt on the pto shaft and on the unloading auger provide essential overload protection. Only after the hydraulic Conax friction clutch is engaged by the spool, do the two 450mm trough augers start running, driven via the bin’s two-speed gearbox. This clutch also serves as a slip clutch that will protect against overload and foreign objects in the trough augers.

The two-speed gearbox at the front allows you to change the transmission ratio by simply switching the driveshaft to the free stub. High speed is for unloading grain, the lower speed for fertiliser or seed.

As well as changing the pto shaft speed, you can also alter the delivery rate by operating adjustable gates — one is above the augers in the trough and the other is inside the bin in front of the sump of the unloading auger.

500 tonnes per hour

Unia quotes a maximum unloading rate of about 500 tonnes per hour, which means that in theory you can empty the bin in 3.5 minutes. We measured this in the field and found the 500mm auger spewed out around 7.5 tonnes of wheat per minute with the gates over the trough augers half shut. With the optional hydraulic spout (€1,400), we could better target where the grain was landing, which overcomes the issue of not being able change the angle of the auger.

Measured at the bin’s spout, the maximum loading height is 4.40m, which is not overly generous for filling trucks. With the end spout pivoted in against the auger pipe, it is just 4.10m. Without these optional extras, the loading height is more in the region of 4.90 metres.

You will also need to check your combine can reach over the 3.60m high sides on the Bizon 36; indeed, the frames for supporting the roll-over sheet are even higher again at 3.92m.

When changing over crops, six hydraulically operated gates under the trough augers and a flap below the unloading auger allow easy cleaning of the sloped sides in the lower part of the bin.

Further details

- A fire extinguisher sits on the drawbar.

- There are two inspection windows in the headboard. An optional work light is also available.

- The handbrake function is provided by a spring-loaded brake.

- The optional weighing system (€4,200) uses six load cells, which are positioned between the frame and the bin. It comes with an optional cab-based printer (€900). It’s also worth noting that the weigh system can be retrofitted.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.