The Tempo set off from the racing blocks 14 years ago. Now there’s a new generation that aims to shift things up another gear.

KEEPING IT BRIEF

- Väderstad is ushering in a new, faster generation of planters.

- The basis remains the same, but there are over 30 changes.

- Sowing depth can be adjusted electrically as an option.

- Will not be available until later this year.

The Tempo evolution continues: the unveiling of a new electronic control system, the Workstation 10 or WSX for short, was the instigator for the new generation of Väderstad precision planter, with around 30 changes to how it places seed accurately in the ground.

There is one WSX control unit per planter unit, which has allowed Väderstad to add features such as curved line compensation, variable seed rates per row, individual hydraulic pressure and automatic stripper adjustment, as well as row lift-out in the tramlines.

At the same time, there has been a switch from 12V to 48V on-board electrics, along with a revised wiring layout, which sees just four wires instead of up to 70 routed to each row.

As part of the move to Tempo II, the 48V system will be standard; however, WSX remains an optional extra for row-specific coulter pressure or electric adjustment of the scraper, depth or press wheels. The seeders and micro-fert unit feature new brushless motors with CANbus control.

If you like the sound of all this, then don’t go rushing down to your dealer just yet; full production will not start until the second half of this year. The various frame set-ups (Tempo V, F, L, T and R) remain unchanged, as do many details and equipment options. The generators stay as standard.

The 30 details

To start with, there is a fully reworked, parallelogram-mounted row cleaner option. This can be pressurised or let float without tools by repositioning a spring to one of several notched positions.

When the opening discs between the gauge wheels show wear, you no longer need to remove shims to re-tension them. Instead, the discs are now re-set by tightening them to a specified torque. It would be useful if Väderstad was to supply a suitable torque wrench with the drill. The discs are now mounted at a 1° steeper angle to reduce the inevitable wear.

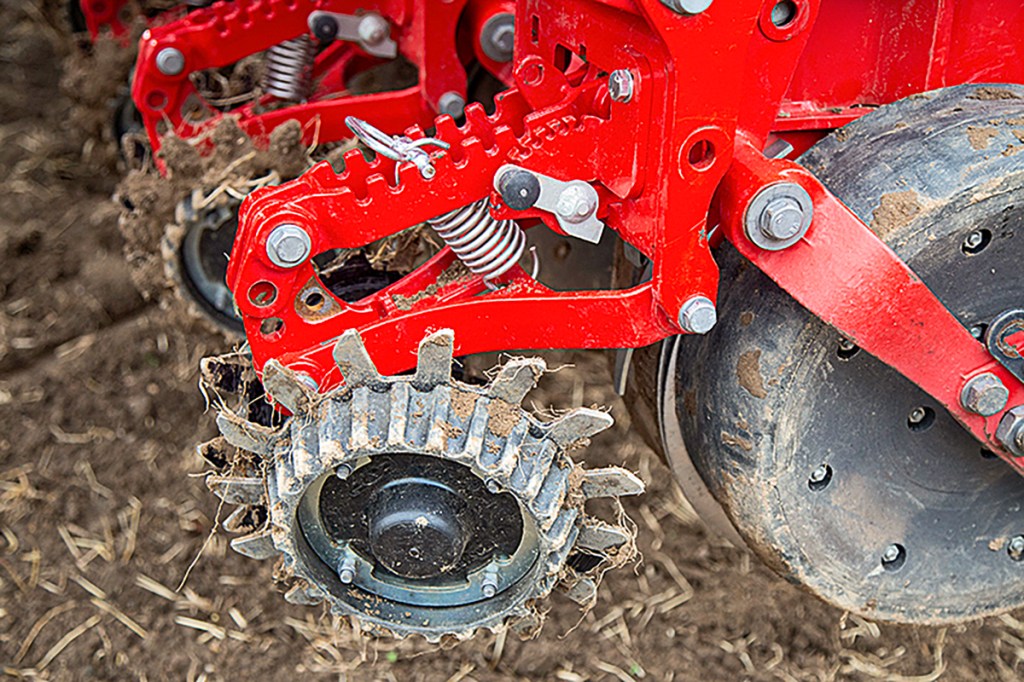

Swapping 16mm and 22mm seed tubes has been made easier, as you just need to loosen a screw on the underside; the gauge wheels and discs remain in place. Väderstad also altered the shape and angle of the seed tube and its clearance to the catch wheel to improve accuracy. The photocells now have dust compensation and a cleaning alarm — a handy feature when sowing fine seeds in dusty conditions.

The cover for the seeding unit has a more comfortable elongated handle for opening it. Behind this is the optimised seed feed slide so you don’t need reducers for small seeds. Also, inlets in the delivery tubes and the ejectors in the covers can be replaced more easily now. The seed hoppers still hold 70 litres. Tank shape has been improved, making emptying a lot more straightforward. Speaking of which, the right-hand chute, complete with a flap for reaching through to the front, has been redesigned for better access.

More remote adjustments

Completely new is an electronic depth control system (a £3,000 option). For this, and also the manual version, the adjusting mechanism was reworked: an eccentric rotary adjuster now allows depth changes in 1mm increments instead of 5mm. On the electronic version, the desired adjustment increments, as well as separate depths, for instance in wheelings, can be set.

On drills with electric depth control, the terminal shows the current seeding depth in centimetres, although this doesn’t always match what is happening when in varying soil types. The system has to be calibrated several times per season using the supplied gauges. If you want to make full use of the depth control, you can assign the function to an Aux-N button. Application maps can also be used.

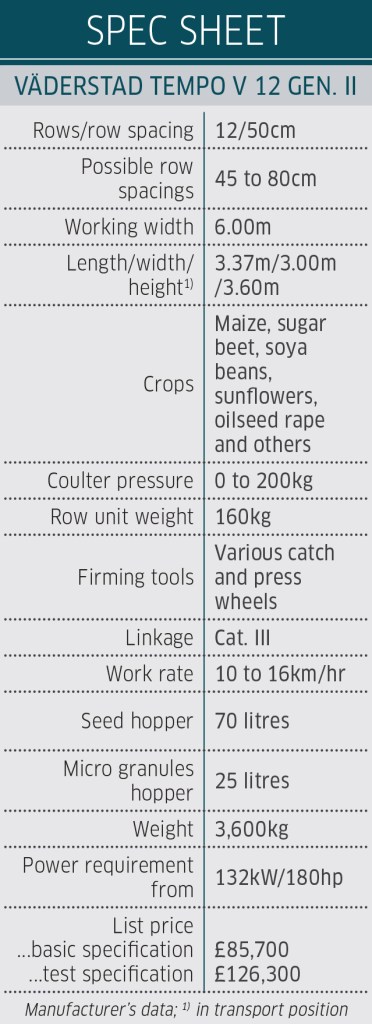

Another neat new feature is an electronic pressure control for the press wheels. Here, a linear motor preloads a spring. The angle is adjusted manually as before. There is still a choice of different catch and press wheels.

Strippers and ground contact

The optional automatic stripper control is still available; this system alters the stripper electrically, based on the recorded misses and doubles (a £2,200 option). The machine in last year’s comparison test (profi 3/2025) was already fitted with this.

Moving on to coulter pressure. As before, you can choose between mechanical spring adjustment or two hydraulic auto functions. On one system, the load placed on the gauge wheels in each row is measured; on the other it is measured only in selected rows. Both systems allow operators to set the ground pressure in kilograms on their iPad — or now also on an ISObus terminal.

As a new feature, the device shows how often the downforce on the gauge wheel drops below the specific threshold limit (for example, 10kg, which translates into no soil contact at all). This is a feature that farmers in the US have been asking for. The hydraulic system (a £9,700 option) allows operators to take up to 250kg off the seeder units or load them by up to 200kg. Each row unit on the machine featured here weighed 160kg, about 30kg more than before.

The user interface is as straightforward to use as before. With this new generation, Väderstad has done away with its dedicated iPad holder. If you want physical buttons, then you’ll need to opt for an Aux-N joystick. Adjusting the sowing depth with a joystick will see an information message pop up on the display.

Other bits

- A separate update for the fertiliser equipment will follow.

- The Tempo L will feature 90-litre seed hoppers; central tank machines will get new 5-litre hoppers for crops such as rape and beet.

- The microgranular hoppers now hold 25 litres.

- ISObus-controlled tramlining (Tramline Control) is available. Online connectivity will be possible later on with a telemetry unit.

- List price of the machine tested is just over £126,000.

Summary

At Agritechnica 2025, Väderstad ushered in a refreshed Tempo era: a revised electronic architecture and significantly updated row units are designed to improve the versatility of the drill as well as increase precision and operator comfort, especially when changing crops. Straight from the factory, the Tempo can now be specified to any level — from a cost-conscious version all the way up to a drill with electronic depth and press-wheel pressure control.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.