When Valtra’s four-model G-series was first introduced as a replacement for the lower horsepower Ns, our featured test farm had high hopes it could surpass a 14,000-hour N123. So, after four years and just over 7,000 hours, is this G125 Eco now hunkered down for the long run?

KEEPING IT BRIEF

- Powershuttle integrates park lock and reduced idle speed

- Radiator cleaning is challenging

- Rear quarter-light windows open backwards

For the last four years, our featured long-term Valtra G125 Eco’s clock has ticked its way up and up, already passing 7,080 hours. This busy little beast has had constant workouts with a diet feeder, straw chopper, rake, round and square balers and a variety of silage and grain trailers.

In daily use on a 1,000-head mixed farm in Dorset, it’s no wonder those hours have been racked up in double-quick time. And our test team remains pleased with the tractor and its performance.

A new addition

When it was revealed towards the end of 2020, Valtra’s G-series brought a four-model range comprising G105, G115, G125 and G135 variants. Lighter and shorter than the N104, 114 and 124 it replaced, the G uses a cab frame taken from the smaller 75-130hp A-series.

Power comes from an AGCO Power 4.4-litre engine that is built in China, which ticks the EU Stage V emissions box with DPF, DOC and SCR. Regen intervals should be around 600 hours, tying in with service requirements, and the introduction of a dual output model – the G125 Eco as featured here – gives higher torque at lower revs, from the push of a button. All models offer boosted power for field and road work once the forward speed exceeds 7km/hr.

The G is a platform shared with Massey’s 5S, so behind the revised AGCO Power block is a 24×24 GIMA transmission from the Massey 5700S, giving six powershifts in four ranges (A-D). A creeper option doubles up the ratios. Some automated shift functions and cruise control add to the operating experience. The powershift transmission is available with HiTech, Active and Versu specifications. There’s a CVT option too, but only for Active and SmartTouch derivatives. Both boxes top-out at 43km/hr.

At the rear, the G packs a 5.7 tonne lift capacity, with 3.0t available up front, plus a 1,000rpm front pto option, adding to the flexibility. Rear speeds can be 540 and 1000, or 540, 540E and 1000. There’s also a ground speed option on powershift-equipped tractors, with Sigma Power available for all pto use, except 540E.

A gross weight of 9.5t lets this 5.14t tractor series handle a payload of around 4.36tonnes, and the G can also be given Valtra’s Unlimited treatment, for those keen to add options.

Sticking to what you know

Our test crew is no stranger to the Valtra brand, having stepped into the Finnish maker’s line-up in 2002, and with good dealer support along the way, it has never looked back – or felt the need to look elsewhere, yet.

This G125 Eco is one of seven Valtras in use with the farm crew, and all but one of them are four-potters. Without a telehandler, six of the fleet also carry loaders, increasing versatility when working around the various dairy and livestock units farmed.

Our featured G125 Eco in HiTech specification was a one-year old, secondhand purchase, having clocked up just under 200 hours with its first owner before it went back into the local dealer’s inventory before being snapped up. It was, as good as new. Buying used means the specification was fixed, but there’s nothing really missing from this model that our test team would have wanted as extras, aside from an extra spool valve.

It didn’t arrive with a loader, but was equipped with brackets ready to carry one of the existing on-farm booms, and in just three years, our test team has piled on more than 6,800 hours.

Air brakes, push-back pickup hitch and air conditioning were essential requirements, as were lots of work lights for dealing with long winters bobbing in and out of sheds. The original work lights have been replaced with Kramp versions, which offered a plug-and-play approach, banishing mid-winter gloom. Large diameter rear LED’s were an early purchase, before more compact and more powerful units became available.

Mirrors are another test team modification, after the OEM versions fell casualty to traditional buildings. Sourced through a well-known online marketplace that sounds like a Yorkshire beach, the double-lens items provide a wide-angle view below the standard lens view, reducing blind spots around the cab.

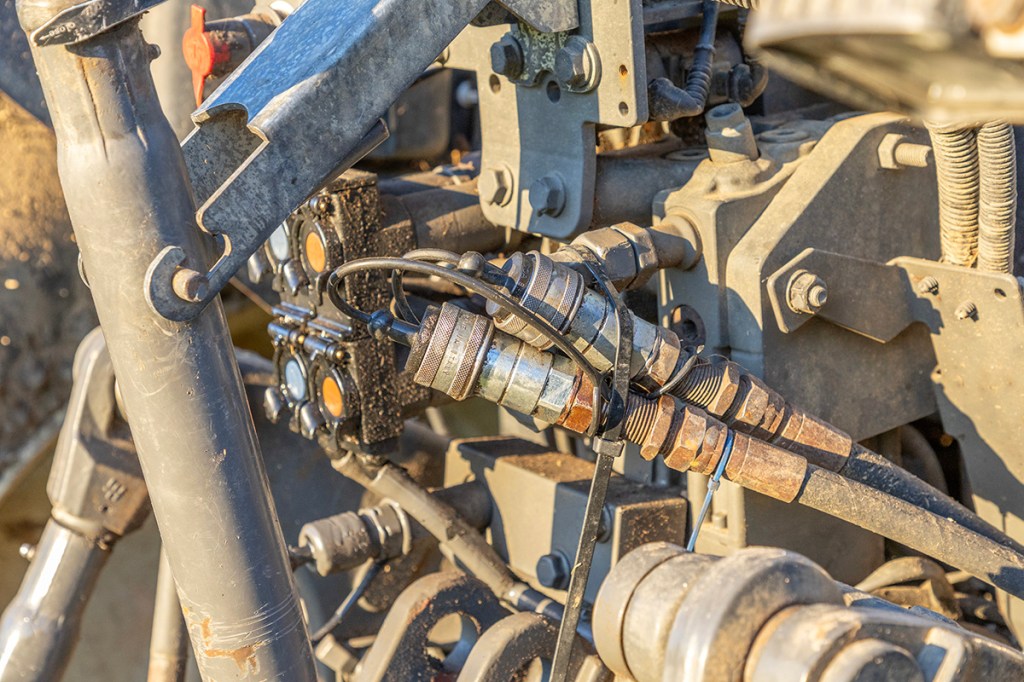

Spot of plumbing

This HiTech model came with only two mechanical rear spools, and could have done with at least one more to run some of the kit in use at the farm. The answer was to run a pair of pipes from the loader’s hydraulic services block to the back of the tractor. This way, one of the loader’s functions can be used when a third supply is required.

Loaders are said to be so easy to get on and off, that when the G125 is involved in field work or trailer haulage, it’s loader is dropped off in minutes and left in the yard – unless it is required for bale stacking, for example.

Over the years, the test team has standardised on loader connectivity, removing any quick attach valve blocks in favour of individual hose connections. Again, it’s down to simplicity and compatibility of using any loader on any of the farm’s Valtra tractors.

Being loader-biased, this G125 has been equipped with rear wheel weights – a pair of 50kg Agco rings are fitted to each side, but are bolted on using the wheel nuts, and not fixed separately onto the wheel dish. A replacement handbrake cable, fitted by our host farm, needed the wheels removed to access the old cable and install new, and that meant weights off first. Six of the tractor’s eight wheel nuts secure the weights, which was said to be an inconvenience when it came to getting the back wheels off.

Changing footwear

When new, this Valtra G was supplied to its first owner on turf tyres, and the dealer swapped these for ag-pattern items. It sees 460/85 R38’s on the back – and the Ceat branded items are recent replacements to the OEM boots.

Despite the narrow stance, the tyres still protrude outside the rear wings, so dirt and muck gets thrown up and over the sides of the tractor. Worse still, the back of the wings don’t wrap down over the rear wheels anywhere near enough, amplifying the problem. Wing-mounted push buttons are frequently plastered with muck and mud being thrown off the tyres, and they’re mounted quite high up the wings, making it a stretch for two of the farm’s shorter operators.

Our test team has looked into adding side extensions to cover the tyres, but the only options available make the wings sit wider than the tyres themselves – and the risk of damage in buildings has offset this benefit.

Getting into the cab has been made slightly trickier with the loss of the lower left-hand step. This was damaged, and eventually removed. Having a steering column assembly that pushes forwards out of the way via a floor pedal is a big win, given the constant climbing in and out of the cab on winter stock duties. And this simplifies access and egress with the six-post cab.

The right-hand lower step is a tuck-away item, and to prevent this from being damaged, it remains tucked away and not used. Above it is the battery compartment, and compared to others on the fleet, the G125 gets a small battery. Given this is only a four-year old tractor, the original battery has already been replaced.

Office space

All have praise for the cab, and while it’s not overly-generous with internal space, there’s ample visibility and headroom, with lots of adjustment on the heated air-seat that came with the tractor. As well as the flat-floor design, the cab is brightly finished with light greys up top and darker plastics lower down, that are better at hiding grime.

There is a noticeable lack of space for the obligatory lunch bag, when spending long days in the field, and nowhere to keep bottles of drink chilled. In addition, the six-post cab’s two rearward opening side windows are considered to offer no benefit for ventilation unless you’re travelling backwards. All agree that these windows open the wrong way, when you want a break from an air-conditioned environment.

A fixed, polycarbonate roof window adds visibility for loader work when stacking bales, for example, but it’s not easy to keep clean, and involves climbing to properly access.

With mechanical spring suspension under the cab, and front axle suspension, comfort is good. But the use of a loader has resulted in the front axle’s kingpins already being replaced, and was a task carried out by the host farm.

Where the younger generation likes the layout of spool levers and the loader’s integrated joystick control – it sits on the armrest – the older generation considers spools are just a stretch to reach comfortably. Some in-cab buttons have started to lose their identification, with markings that are being rubbed off given the constant use.

The grunt

Performance gets a thumbs up. The gutsy four-pot engine pulls well, and is rarely found to be short of power for the tasks it carries out. The Eco mode though – which is effectively a switchable map – brings power and torque in a bit lower down the rev range. Excessive use of this has been found to trigger regen issues, often leading to a dealer call-out and a reset, so its use is now minimal.

Excessive idling is another cause of regen issues and given that the tractor doesn’t get a lot of hard work, it’s an unfortunate consequence of emissions paraphernalia. When the dash throws up a DPF light, the team says the tractor needs to be thrashed to help it clear its throat.

Fuel use isn’t excessive, and the 200-litre tank is more than enough for a long day’s work, and the operators put this down to the tractor not carrying out full load pto work. A failed DEF injector has needed replacing – again carried out by themselves to save on labour charges – with the dealer carrying out coding and resetting as required. Not an easy task given its concealed location in the exhaust after-treatment package shoe-horned onto the right-hand side of the little G.

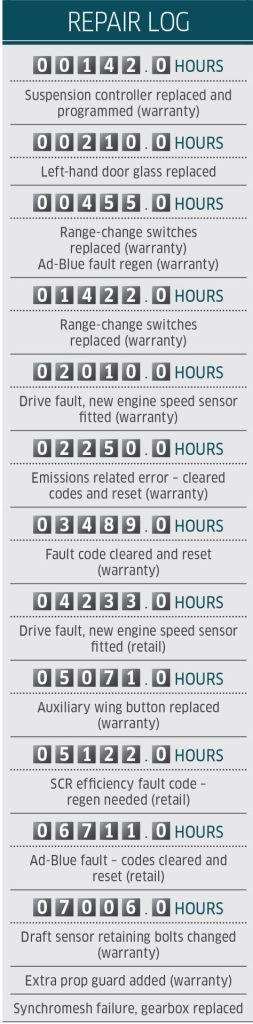

A glance at the repair log shows this tractor has needed a few on-farm fixes in the last four year, mostly with electrical issues that have been swiftly rectified. On more than one occasion, transmission switches have plagued the downshifting, and a total drive failure was traced back to an engine speed sensor fault.

In the last 100 hours, the transmission has been out for a failed synchromesh unit, following a persistent noise emanating from the top of the gearbox over the last few thousand hours. The transmission shifting though, has been generally very good until the range-change switches fail.

Service access has been called into question at times by our team, adding that the loader brackets that shroud the engine compartment are part of this issue. A compact, fixed cooling pack that leans backwards might aid forward visibility, but is not the easiest to clean. Two clip-on plastic side panels that encase the space between intercooler and radiator allow hand access to pull out debris. A good airline and blow nozzle is needed here, though they report no issues of over-heating. The bonnet catch has also been modified so it no longer needs the ignition key to get into, simplifying access and improving convenience for daily checks.

Summary

The G125 is considered by our test team as a good all-rounder, capable of most tasks around the business. Back-up from the local dealer has retained brand loyalty, with the tractor favoured for its simplicity. And while the team has no concerns over mechanical reliability and its general build quality, there are small doubts over the tractor’s long-term future based on its catalogue of minor failures involving electrical items and sensors. Will it get close to 27,000 hours? Quite possibly, but at what cost? Only time will tell.

Geoff Ashcroft

For more up-to-date farming news click here and subscribe now to profi and save.