If you’re not satisfied with the wide selection of self-propelled sprayers on the UK market, then this Dutch creation might pique your interest. The intriguing machine uses a mix of Fendt tractor and CHD sprayer hardware.

KEEPING IT BRIEF

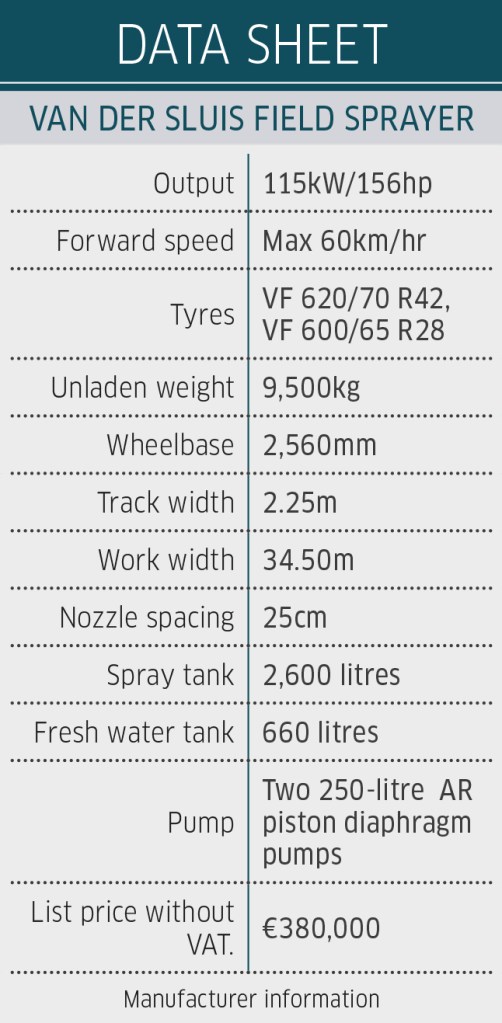

- This self-propelled is from Van der Sluis based in Northern Netherlands.

- Host vehicle is a Fendt Vario

- 514 Gen 3.

- Price tag is in the region of €380,000 (£325,000).

Based on a standard tractor and a mounted sprayer, this self-propelled sprayer was created by agricultural machinery dealer Van der Sluis from the North of Holland. The dealership began thinking of ways it could improve crop care applications for its customers 30 years ago. The five-depot dealership is surrounded by mainly vegetable and flower bulb producers who all have specific, special demands from their pesticide application equipment.

For instance, with the narrow headlands, which are not used to grow vegetables or bulbs, having a machine as physically compact as possible is a priority. This is even more understandable when you learn that land prices in the area amount to €200,000/ha, so the smaller the area not making a return the better. Field sizes are also relatively small: 3.0ha is the average in this region and the vegetables are sown in stages, so a large tank is not required. That said, boom widths are often considerably wider than the ones we’re used to seeing.

The chassis

The self-propelled sprayer is based on a Fendt Vario 514 Gen3 with Profi+ Setting 2 equipment. The 156hp tractor was fresh out of the box when it was ordered with the conversion in mind. Equipped with a third screen in the cab, a second joystick (3L joystick) and a full guidance system that can also take care of section control and variable rate, it offers a professional and sophisticated level of equipment.

As a first step, the cab, the front linkage, the bonnet and the front mudguards were removed at the dealership. Van der Sluis then transported the tractor by truck to a local metal fabricator, who made a bespoke frame on which to mount the cab. This was attached to the mounting points that used to carry the front linkage. Under the cab, the metalworkers installed a lockable box for storing various cans, which is nice and easy to get at. In addition, two 330-litre clean water tanks were installed in the now vacated wheel arches either side of the cab.

Last, the tractor travelled 200km to sprayer manufacturer CHD, which then kitted it out with the required spraying hardware.

The sprayer structure

Spray kit consists of a 2,600-litre tank, a platform with a large hatch to climb through and a 34.50m wide boom. The spray tank is split into two compartments, because the plots are usually small and farm-to-field distances often long. The front compartment holds 1,080 litres of liquid. The other holds 1,520 litres and is always filled with fresh water, which allows the operator to prepare a mix for just 5ha (at an application rate of 200 litres/ha).

The system can then be cleaned with the 660 litres of fresh water and a new mix can then be prepped for another crop or plot using fresh water from the 1,520-litre tank.

The 2,600-litre water volume can be used to treat around 12.5ha at an application rate of 200 litres. If the fresh water from the two small tanks is not used for cleaning, it can also be used for spraying. So, there is enough water on board to treat nearly 16ha. Two 250-litre AR piston diaphragm pumps take care of the pumping.

The boom has an air sleeve to minimise drift. According to the dealer, this is also necessary, because the sea is just a stone’s throw away. Triple nozzle holders are also fitted so that they can be changed quickly when swapping to a different crop. In order to remain compact and manoeuvrable on the road, a four-part folding linkage was used, which doesn’t stick out as much to the rear as a three-point linkage.

Operation of the self-propelled

The self-propelled sprayer is operated like a tractor with a trailed sprayer: all tractor functions are the same as before, and the sprayer is worked using ISObus. The two joysticks on the tractor can be assigned to different functions.

Nevertheless, there is still an emergency control from CHD that can be accessed to operate the boom sections and functions. Section control and variable rate are run through the GPS receiver and the Fendt terminal. The images from the cameras under the tractor and the reversing camera can also be displayed here.

The sprayer has its own oil circuit to drive the pump and fan, which is operated by a pto pump. All other functions are supplied with oil from the tractor via its load-sensing plumbing.

All parts are original

The dealer attached great importance to using only standard parts for the conversion. Customer requirement was that the supply of parts was reliable and a comprehensive dealer network was in place. For this reason, they relied exclusively on Fendt, CHD and BBLeap. Another detail is that the Vario 514 can easily be converted back to a regular tractor when selling it. This ensures a higher resale value than with a more ‘normal’ self-propelled vehicle.

The price

The final price of this special construction surprised us in comparison with a purpose- built self-propelled. When you consider that the list price of the tractor alone is over €200,000, and that a trailed sprayer in this spec can easily cost €100,000 euros, then the purchase price of €380,000 is not so hard to justify. This price puts the small self-propelled vehicle in a similar ballpark to a dedicated self-propelled sprayer.

Spraying

We were able to use the Sluis sprayer on a vegetable farm near Amsterdam. Here we applied fungicides to celery and lettuce at a rate of 200 litres/ha. We were impressed by the simple operation, because any driver who is familiar with Fendt controls will get on this machine and be able to crack on. In terms of driving comfort, the self-propelled is in no way inferior to a tractor. Thanks to the tall tyres, it can travel at 60km/hr on the road.

The split spray tank proved to be a great advantage when changing fields and crops, saving a journey back to the farm. The air system on the boom reduces drift, which was particularly noticeable in the windy conditions. Thanks to its short wheelbase, this machine is able to turn on a 4.0m wide headland!

THE FIRM BEHIND THE SPRAYER — B4AGRO

The self-propelled sprayer is used on the Dutch farm B4Agro in Warmenhuizen, which farms around 130ha, growing various types of lettuce, celery and cabbage. Every day, 180 pallets of lettuces are delivered to a neighbouring wholesaler.

A few years ago, an indoor farm was built for 9 million euros, comprising a hall with a vertical farming system and a 3ha greenhouse with hydroponics. Here, the lettuces were automatically sown and then supplied with controlled amounts of water, CO2 nutrients and light in the vertical farm. Growth and shape of the lettuce is controlled by different light colours. After 20 days, the lettuce plants are transferred to hydroponics, where they are suspended with their roots not digging into soil but in a water-nutrient solution. About 6.5 weeks after sowing, the lettuces are ready to harvest.

This is no longer so, because the indoor farm was shut down after just three years of operation due to rising energy prices and competitor offers from Spain. The farm is currently trialling how the system can continue to be used. Growing cannabis was also considered an option but was not authorised by the government, because the planned annual production volume was too low.

In addition to growing vegetables, the farm also operates a digester. Every year, 18,000 tonnes of lettuces and vegetable waste and unsold produce are used as substrate. The vegetable residues produce about 50m³ of gas per tonne. Another fuel is cocoa bean shells, 7,000 tonnes of which are digested every year, producing about 500m³ of biogas per tonne. The gas is processed and fed into the natural gas grid. The filtered CO2 can be used in the greenhouse.

The farm is fully mechanised. In addition to a self-propelled slurry tanker, there are four self-propelled lettuce harvesters, four lorries, six tractors, three irrigation systems and a wide range of attachments. The company employs 50 people.

Summary

The bespoke construction by agricultural machinery dealership Van der Sluis is a specialist solution for vegetable and flower bulb farms. Today, the dealer can call on 30 years of experience in the conversion of tractors into self-propelled sprayers, even though it has converted only two Fendt tractors to date. Previously, it used John Deere tractors.

The new machine is equipped with modern technology, and its short wheelbase means that headland widths can be minimised. The split tank makes the self-propelled vehicle flexible and saves unnecessary journeys. The price of the machine is surprising and places it in the mid range of self-propelled sprayers.

Sebastian Rüther

more up-to-date farming news click here and subscribe now to profi and save.