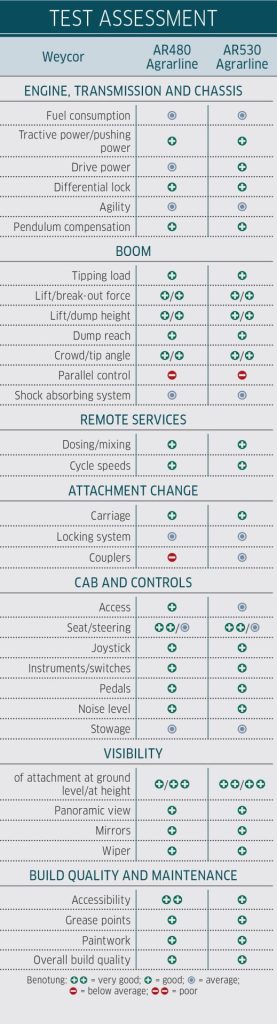

Weycor has two wheeled loaders that sit in the 6.0t class, yet there’s a whole pile of differences between them. We put the AR480 and AR530 to the test.

KEEPING IT BRIEF

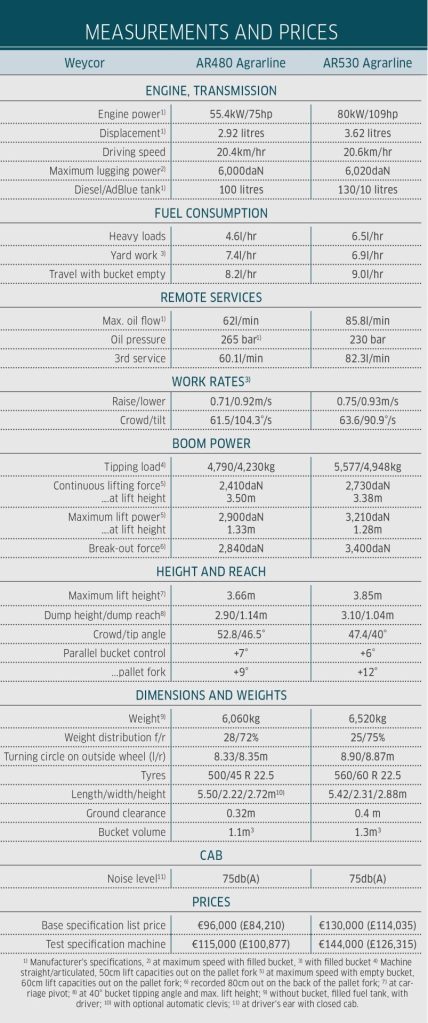

- The AR530 comes with a 109hp motor and can lift around 20cm higher. But it needs AdBlue.

- The smaller AR480 is just 75hp and is that bit smaller in stature.

- Our Agrarline test AR480 lists at €115,000 while the AR530 is €144,000.

Weycor is upping the ante for the farmer and contractor market, donning new green paint work in place of the more familiar Atlas Weyhausen orange, which is now solely reserved for the construction sector. But fresh paint isn’t the only change featured on the new Agrarline models, which get wider agricultural tyres and a longer reach boom. Our two test candidates were among the first to sport the new ag livery.

What are we looking at?

Our AR480 sits at around 6.0 tonnes, as it was kitted out with the optional 300kg rear counterweight and 110kg of ballast on either side of the front axle; this helps improve its stability when on the road. The 480 is also slightly more compact than the bigger ‘5’ series AR530 which can lift more weight and raise its boom 20cm higher. The 530 also bags 34hp more from a bigger motor, but this also pushes it into a different engine emission bracket, meaning it needs AdBlue. The AR480 doesn’t need an SCR unit, at least not yet.

Long boom

Both test candidates were equipped with the 2.70m boom. Weycor also has a shorter boom which, although it can lift almost 20% more, has a reduced lift height of around 35cm.

The North German loader maker specifies a tipping load of 3,481kg for the AR480 when fully articulated, and 4,070kg for the AR530. We measured the continuous lifting force and found there was a difference of under 300daN (AR480 = 2,410daN, the AR530 = 2,730daN). There was a bigger difference in the breakout force.

While the 480 has a simple, central Z-bar linkage, the 530 has a double Z-kinematics which achieves a higher tear-out force with its tail starting to lift at about 3,400daN. The AR480 is also able to raise its backend as the bucket scoops out of a pile, but at a lower figure of 2,840daN.

Compared to the AR530, the crowd and dump angles on the 480 are slightly smaller due to the double Z-bar, yet they are still acceptable figures (see page 44). The general view forward is also better; however, the extra linkages at the sides do make it harder to see the headstock’s coupling points when picking up an attachment.

Almost good

On the hydraulic quick-attach headstock, you first press a button on the side console and then operate the third service to open the locking pins. An audible alert sounds while the button is engaged. Unfortunately, the 40mm locking pins extend as soon as the switch is released — but not fully, and sometimes only on one side. This can cause the coupling eye to hang in front of the pin and risk incorrect locking. Thankfully, the locking points are clearly visible from the cab so you can see them to doublecheck all is well.

A Euro carriage will be available for the 480 in the future.

The hydraulic couplers for the third service did come in for test criticism. The couplers, particularly on the AR480, are positioned so tightly to the headstock that they are really hard to use. Weycor says it is going to sort this out. The screw-on connectors on our machines were not everyone’s cup of tea, though they can be connected while under pressure — which is helpful when using a silage grab.

For pallet fork work, precise parallel control is key. Both loaders crowd the attachment relatively sharply (AR480 9.0°, AR530 12°). This is a downside of the Z-linkage, which is primarily designed for aggregate bucket work. With the general-purpose bucket, the parallel lift is a lot more precise, only tilting the bucket a few degrees.

More hydraulic oomph

For the hydraulics on both machines, Weycor relies on a constant-pressure Linde gear pump supplying at 60l/min (AR480) and 85l/min (AR530). However, for our type of work, we’d definitely go with the optional 100l/min axial piston pump for €3,500.

Staying with the hydraulics, both the 480 and 530 have boom suspension. This activates when the joystick is locked via a button or when automatic transmission (active from 6.0km/hr) is engaged.

Unfortunately, this cushioning feature has to be reactivated after each engine start.

Comfortable working place

Get on and drive off. And with both Weycor machines it is that simple. The two share the exact same, inhouse-developed cab, which offers a functional, comfortable, and well-finished workplace. The only downside is that the cab is a bit too short for the tallest operators.

To reach the high-up cab you have to stretch to find that first step: 55cm on the 480 and 60.5cm on the 530. This is partly to do with the large tyres on the agri spec machines. A third step would make sense, and again is something Weycor says it plans on fitting.

The one-piece doors on both sides can swing open 180⁰ and be pinned back open, and the release is easy to reach from the seat. The optional, and recommended, Grammer air seat offers very good comfort.

The height and angle of the steering column/dashboard can be adjusted by using two levers. The oil flow rate for the third service is also controlled from here. As an option, the loaders are even available without the small information display, which reduces the price by around €2,000. The adjuster for setting the armrest fore/aft position as well as the angle lies within easy reach and is a nice touch for added comfort.

The joystick is kept simple and works via a hydraulic pilot control — mixing and control of the functions is fine on both machines. There is an optional joystick with an extra rocker switch for the fourth service. You can’t adjust the sensitivity of the joystick. A decal clarifies the controls such as the button on the back for the effective 100% diff lock.

Overall, the view is good thanks to the high seating position of the flat-floor cab and the low windows. We weren’t too keen on the Weycor logo at the top of the windscreen, as it’s in the way when using the boom up high, but it is something you can deselect when buying the machine. Bizarrely in a world of health and safety, Weycor doesn’t currently offer a rear-view camera on the bonnet — we would like to see this added to the options list.

More power under the bonnet

The AR530 model with its 80kW/109hp, four-cylinder Deutz motor not only has more horses under the hood than its little brother but also more technology. At first glance, the exhaust aftertreatment system above the engine, along with the radiators on the right- and left-hand sides (for the engine and hydraulic oil) are very prominent. Despite this, accessibility is fine, except for the high-mounted gas cylinder release.

There is considerably more space under the flatter bonnet of the AR480, which has a Deutz TD 2.9L4 with 55.4kW/75hp; this size of engine can still manage without SCR.

However, we have to criticise the diesel tank filler on the 480: the shallow angle means the nozzle easily slips out. Neither machine has a chain for the fuel tank cap.

Speaking of fuel, the compact AR480 scores test points with its low fuel use while doing handling operations around the farmyard. However, when it comes to covering longer distances and road work, the 75hp engine reaches its limits with the six-tonne loader — this is noticeable both in terms of speed and diesel consumption. Due to the larger motor, the bigger 530 will use slightly more fuel, but it can also shift a bigger load, and this is where it had the advantage when covering longer distances around the yard. The optional wide tyres also have a slightly negative effect on diesel consumption.

Both models use an identical Linde hydrostat for propulsion. The axle ratio of the AR530 is slightly shorter which, together with the higher engine power, means it doesn’t die off as quickly as the AR480 when travelling uphill. However, both units are somewhat reluctant to climb steeper hills on roads — a consequence of the single-speed hydrostatic transmission without a gear shift in the 20 km/hr version.

Three pedals

Weycor relies on a three-pedal drive system. There are the usual drive and inching pedals and then a suspended (emergency) brake pedal on the right, but it does take a bit of force to operate.

To hold the loader on a slope, the inching pedal can also be fully depressed, which will engage the brakes as well — very good. We also liked the automatic parking brake. One small point of criticism: if the accelerator pedal is touched when starting, the machine cannot be moved and first must be shifted back into neutral. Weycor says that this is a safety function, although it’s one that can cause problems for new users.

Direction of travel is selected with a thumb switch on the joystick. The speed range of the accelerator pedal can be changed by pressing a button on the joystick – from 0 to 7 or 0 to 20km/hr. 40km/hr is an option and requires a mechanical gear reduction that is engaged while stationary.

Power control was fine during our test. To prevent the machine from rolling back on an incline, the brake/inch or accelerator pedal must be used to counteract this — however, starting off without rolling back is doable.

Maximum tyre size

For our test, Weycor supplied the loaders with the biggest tyres it offers on these two machines. The AR530 rolled on wide 560/60 R22.5s, meaning there wasn’t much room between the rubber and mudguard here.

Large wheels reduce the pushing and pulling forces: in our pulling force tests, the AR480 achieved around 6,000daN. And even with significantly more power, the AR530 peaked at just over 6,000daN. Despite the larger tyres, pushing force is adequate for heavy work in the soil heap.

The two machines rely on axles from Dana Spicer, albeit with different dimensions: the AR480 sits on 10-tonne axles, whereas the AR530 has 16-tonne axles.

While the chassis of the AR480 is somewhat slimmer, Weycor uses the same oscillating pivot steer in conjunction with rigid axles — both here and on the AR530. To ensure good stability, the joint is tilted forwards by 7⁰ and pre-tensioned, which resulted in good driving and static behaviour. The joint allows for 12⁰ of articulation between the front and rear axle and 40⁰ articulation angle. It also has a good grease bank.

Other details

- The supplied attachments made a good impression.

- A reversible fan is not yet available for these models.

- There are two optional LED work lights at the front and rear of the cab roof (halogen headlights as standard).

- Air conditioning is also optional.

- There is a metal plate up on the roof for attaching a magnetic-mounted beacon.

- A grease gun is included as standard, and the 480 even has a holder for it under the bonnet.

Summary

For our test, Weycor sent us a pair of wheel loaders of the same weight class, but with some differences: the slightly more compact AR480 is less powerful, especially on longer distance work where it lags behind its bigger brother, the AR530. However, it doesn’t require AdBlue and is somewhat easier to manoeuvre — the ideal helper on medium-sized dairy farms with short distances.

The AR530 model is bigger overall: it has more technology under the bonnet, larger dimensions, but also more engine power, and it is capable of lifting more to higher heights. This makes this machine a genuine alternative to smaller telescopic handlers, because it’s simple to operate and less prone to wear.

With a dealer price of around €70,000 (£61,403) for the AR480 unit and just under €90,000 (£78,974) for the AR530, there is also a clear difference between the two here.

Both Weycor loaders are not cheap — but they offer honest, rock-solid technology and simple operation.

Overall, we enjoyed working with the two machines in the Agrarline specification. The build quality made a good impression and the level of comfort is excellent.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.