At Agritechnica 20 years ago, Lemken made a big splash with the presentation of its VariTansanit reversible ploughs. Claimed to operate behind smaller tractors, be more fuel efficient and reduce wheel slip, the new ‘hybrid’ ploughs wouldn’t, however, live up to all those promises in the following years.

The introduction of the VariTansanit piqued the interest of many farm machinery experts and users. The new and novel design promised so many advantages that anyone planning to buy a big plough simply had to take a look at Lemken’s latest offering.

The biggest selling point of the VariTansanit was its weight transfer system so that even the light but still powerful tractors that were appearing at the time (like the Case IH CVX 195, Fendt Vario 718 and John Deere 7530) could pull more furrows and up the work rate without having to add lots of ballast to gain sufficient grip. Less wheel slip, better fuel economy, higher outputs, the hybrid plough seemed to tick so many boxes.

Hybrid technology in the drawer

It is somewhat strange that the patent for Lemken’s hybrid plough technology was left slumbering in a drawer for 10 years before it saw the light of day in 2005. The concept was as ingenious as it was simple — transfer some of the weight from the plough to the tractor’s rear axle.

The advantage: the tractor doesn’t need to be as heavy (or need additional ballasting on the rear axle), slip is reduced and you get over more ground each day. However, this arrangement also took weight from the front axle, so it was usually necessary to have a decent weight block up front.

From a distance, the VariTansanit actually looks like a normal semi-mounted plough. On closer inspection, however, you notice the low-set and somewhat delicate subframe between the three-point hitch and the rear wheel. Take another step closer and you quickly realise that it’s actually coupled to the tractor like a fully mounted plough. The only difference is the hydraulic top link, which plays an important role in the hybrid plough’s operation.

More weight on the rear axle

A fully mounted plough transfers its weight to the tractor’s rear axle. To help keep the outfit balanced when the plough is raised and give better weight distribution in work, front ballast is generally required. With a semi-mounted plough, however, there is a lot less weight transfer to the tractor. While this isn’t a problem when moving on the road, in the field is when you need traction; this is usually achieved with suitable tyres and throwing in enough bulk to get the job done. And that in a nutshell has been the main tractor difference between handling a fully and semi-mounted plough.

It made sense to the Lemken engineers to combine the advantages of both systems and eliminate the disadvantages. The result was the VariTansanit’s hybrid approach.

Hybrid technology in the test

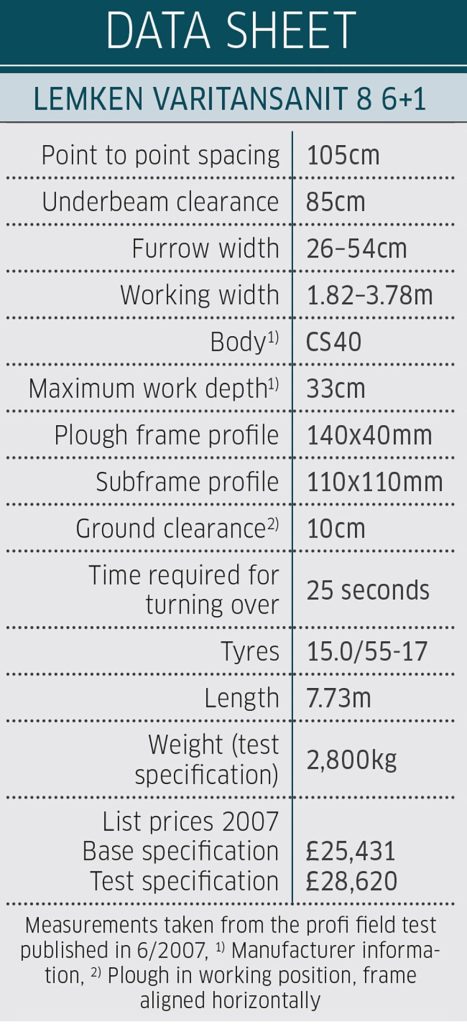

But converting that idea into a working, practical design that could overcome the complex interaction of forces on a plough was a challenge to say the least. However, some initial independent testing with the VariTansanit showed it could be done. We published a test with the support of the DLG Test Centre in profi 6/2006.

In terms of operation, the hybrid plough initially worked like this: from the control box you selected how much you wanted the top link to be pressurised, such as 50%, i.e. 100 bar on a tractor with a max pressure of 200 bar. The resistance of the top link then ensured that weight was transferred from the plough to the tractor. With less pressure on the top link, the resistance then inevitably decreases and the load on the plough tractor reduces, too.

In terms of the tractor wheel slip, the DLG measurements showed an advantage of the VariTansanit over two other Lemken ploughs, the VariOpal (mounted) and VariDiamant (semi-mounted). In the end, the VariTansanit actually achieved a 20% higher output than that managed by the comparison models.

In 2010, a new test by the British research institute The Arable Group (TAG) revealed the fuel economy of the various Lemken plough systems. This comparison essentially confirmed the results from the earlier DLG measurements: there is significantly less wheel slip and fuel consumption with the hybrid plough compared to fully and semi-mounted models.

Hybrid technology in practice

Just how advantageous the hybrid plough design could be was largely dependent on conditions. Lemken recommended a 130-205hp tractor in front for the six- and seven-furrow versions — a broad power range.

In practice, the VariTansanit was not always able to exploit its advantages, particularly over conventional semi-mounted designs. The biggest reason for this was probably the fact that tractor size and power were no longer limiting factors for larger arable farms. In 2014, Lemken decided to pull the pin on the VariTansanit. A total of just 150 units were sold.

Traction boosters still up to date

The VariTansanit hybrid plough may be discontinued, but the design idea of boosting traction is still very much relevant and not only for semi-mounted ploughs. Lemken continues to utilise weight transfer systems on a number of its machines, as do several of its competitors.

Lemken filed a patent application for the traction booster for semi-mounted ploughs in 2010: “An additional hydraulic cylinder transfers weight to the rear axle of the tractor, thereby increasing the traction of the tractor. When the linkage raises the plough beam via the chassis/centre section, the pressure within the traction booster is automatically released. The stability of the tractor is guaranteed at all times. When the chassis/centre section is lowered, pressure is automatically built up again.” Today, this system is offered on the firm’s Diamant and Titan series ploughs

Gerd Theißen

For more up-to-date farming news click here and subscribe now to profi and save.