At Agritechnica, Zürn introduces its new belt header table with flexible cutterbar. We had the chance to test a 9.15m version of the new Premium Flow Flex this summer.

KEEPING IT BRIEF

- The new Flex header is reckoned to give better contouring while cutting close to the ground.

- Belts actively feed the material from the cutterbar to under the auger

- Changing to rapeseed is very easy, just a five-minute job.

The Premium Flow has been part of the Zürn combine header range for over 20 years — a conveyor belt table with a rigid knife. But to give even more precise ground contouring while cutting close to the ground, it is introducing a flexible knife version called the Premium Flow Flex.

Flexible cutting

These new headers have 150mm of vertical ‘flex’ travel. This flexibility is achieved by mounting the cutterbar on swing arm bars that are suspended from the rear of the cutting platform.

While the main weight of header is still carried by the combine, the actual cutting height of the knife is controlled by plastic runners when in flex mode. The current height is measured by the sensors on the four skids or by the sensors on the two float arms on either end.

The cutterbar is sourced from Schumacher. On the 7.60m wide header, this is driven from just one side, whereas, on the wider 9.15m and 10.70m models, the knife is powered from both sides. The knives are synchronised and overlap in the middle.

The Schumacher Easycut II System features roller-guide reciprocating knives. The grain lifters are attached to the fingers without any tools. Zürn says the Premium Flow Flex is currently the only flex header on the market with these new grain lifters. A height indicator on either end of the header shows the current position of the cutterbar. The operator can adjust the Flex float pressure hydraulically from the cab and even set the header to rigid mode.

Belts bridge the table

There are six conveyor belts feeding the cut crop under the 760mm auger. Hydraulic drive to the belts is infinitely adjustable via a pressure relief valve, but in reality should only need adjusting when changing over crops.

For maintenance, the six belt units can be individually swung up out of the way. There is a drawer in each section to collect debris. Belt tension is taken care of automatically with two coil springs.

To protect the cutterbar, the reel tines are made from plastic.

Changing over to rapeseed

The mechanically driven side knives weigh just 20kg and again attach without needing tools. The drive is connected using a dog clutch. The auger can be raised without any tools to ensure more throughput in high-volume rapeseed crops using a hydraulic hand pump.

The crop dividers and the side knives are stored in practical holders.

Performance and price

We used the new header in a crop of wheat. Although our field seemed flat and even, the height indicators very clearly indicated how the flexible cutterbar was adapting to the contours, creating a uniform cut without the knives cutting into the soil. The belts were doing an effective job of feeding the crop, leaving little work for the reel.

From the outset Zürn will offer the new header for Deere, Case IH, New Holland and Fendt combines. The header comes in a high level of specification with the necessary hydraulic fittings, couplers and connectors; the only optional extra are the crop lifters (£600). The price for the 9.15m header is £94,900.

Sebastian Rüther

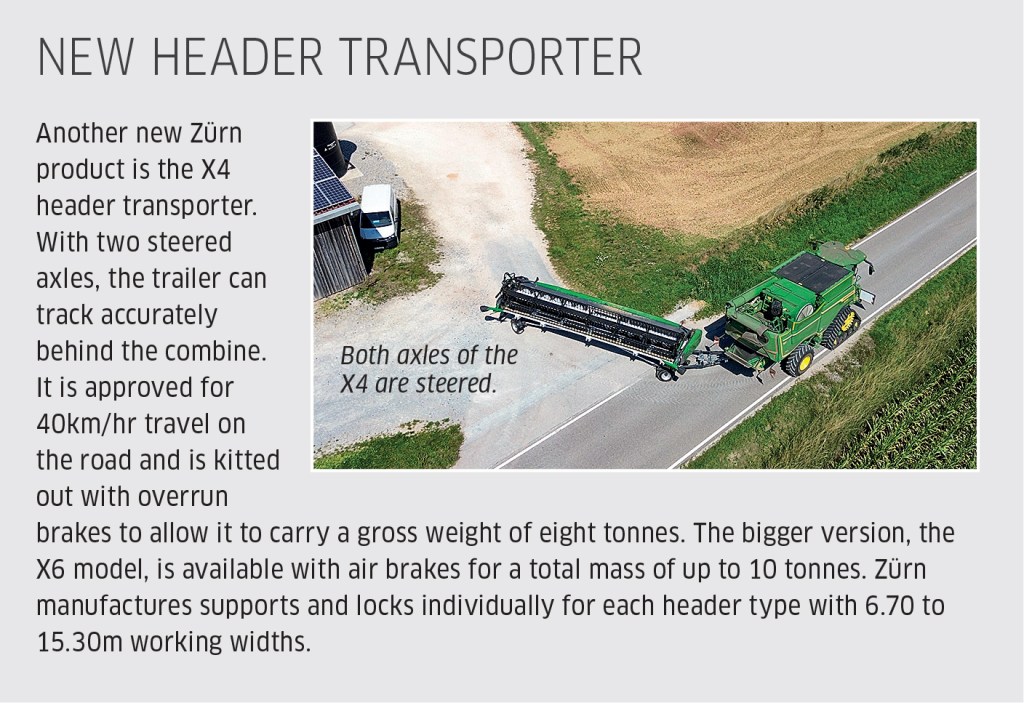

For more up-to-date farming news click here and subscribe now to profi and save.