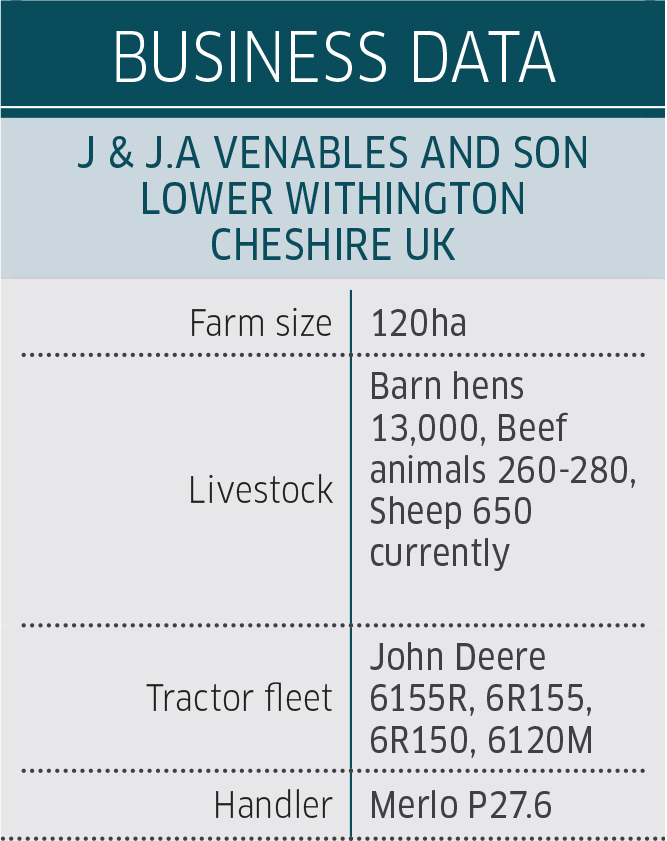

J & J A Venables and Son farm under the shadow of Joderal bank observatory in Lower Withington, Cheshire with 40 hectares of their own, and another 80ha rented, they have grown their business to support three family members and two full time staff.

KEEPING IT BRIEF

- Family farm grows business maintaining multiple revenue streams.

- Farm expands specialist contracting wing to capitalise local demand.

- Expanding poultry enterprise after success with an updated building.

The Venables family have been heavily growing their business over the last decade, and in the last five years they have pushed it even further. With three family members to feed the enterprise is diverse and resilient, and not reliant on one revenue stream to pay the bills.

Currently the three family members working hands-on are dad David, and sons Rick and Will, the farming enterprise also supports two and a half employees. Pretty good going for 120 hectares, with some careful investment over the last decade the family have created a business that bucks the trend of specialisation that seems to have grasped many British farming businesses.

Will and Rick Venables represent the fourth generation at the farm, until Rick left education the farm was quite traditional, with a 40 head sulker herd, 300 sheep and laying hens were the mainstay of the business. And it was only Covid19 that stopped David’s parents being present daily on the farm.

Rick joining the business was the farms first big step in contracting and seeking external work to expand the business for an extra wage. Back then it was by adding a tractor and helping out silage contractors, buying a case Maxxum 130 CVX was a big investment, and served the farm well.

Hen Houses

In 2012 battery housing was brought to a mandated halt, unsure what the future held, David looked for a stop-gap between the old chicken barn, and what is now in use, he found some polly tunnel structures that remained for ten years, these served as hen housing until the family decided to either build a dedicated shed or get out of eggs. It was at this time the youngest member of the family, Will, was coming into the business more seriously, and the trigger was pulled on the purpose-built poultry shed in 2021.

This houses 13,000 free range hens, and produces between 11,500 and 12,000 eggs per day, all of which are graded on the farm. The system is fairly well automated, there isn’t anyone walking around with a wicker basket collecting eggs, they’re brought to the grading room via conveyors, and the grader sorts out the eggs by size.

Egg sales are mostly retail, with good population density nearby trade is reliable to pubs, cafes, and supply to some wholesalers. Milk rounds consume a good percentage of the production, these are boxed eggs rather than trays, with the farm’s unmistakable radio dish and chicken logo.

There is also a farm shop on the front yard where eggs, local potatoes and some preserves are sold, with a tonne of spuds going out of the yard each week, these are sourced from a local grower that rents land from the farm.

The only human intervention is loading trays or boxes onto the line, and periodically moving the extra large or small eggs. “We automatically grade large and medium sizes into trays or boxes, and for the small amount of extreme sizes, we hand pack them – it’s £25K for a packing line, so we decided it wasn’t worth it,” explains Will.

With the next phase currently underway, hen count will grow to 29,000 with 27,000 eggs per day being laid. Due to planning, the new building was positioned behind the existing structure. This has increased the costs somewhat because the existing grading line couldn’t be utilised as would have been possible if the new building was next door to the old

As with everything when building, lessons have been learned, and the new grading room is twice as big to accommodate a more palletised stacking and storing system. Eggs are quite easy to store, shaded room temperature is good, which is for most of the year easy enough to achieve in the UK.

Another benefit of chickens is the manure, the shed produces about eight tonnes per week. Rich in nitrogen and with traces of potash and lime, it saves on fertiliser. The farm has a Bunning disc spreader for this and contracting, so the shed’s automatic conveyor empties directly into it, and it’s deployed to the field, when conditions permit.

Four-legged stock

There have always been cattle of some kind on the farm, whether milking cows, or the sucklers that came before the farm switched to beef production – for many farms of this history and size cattle are almost part of the furniture. The set-up here is to buy in young stock and get them near to finishing.

Belgian Blue and Angus are the beasts of choice, with good marketability and reliable growth rates, they seem to suit the business well. The cattle are grazed outside during the summer, which lowers the labour requirement when there is field work to do.

On average they run 260 to 280 head, buying in at four months and rearing to big store size, this currently works well for the business. A mix of age groups sees the cattle number fluctuate mildly, which smooths cashflow and logistics. Selling before finishing also avoids the cost of pushing for the last 50-100kg which can be expensive as the farm has minimal arable acres, and no barley is grown.

The growth rates drop off a little while they’re outside. “We get around 0.7-1.2kg/day when they’re outside, that goes up to 1.7-1.9kg/day when they’re housed,” points out Rick.

The cattle are fed haylage which is produced on the farm. “They like the greener younger grass, it’s almost like a dairy silage, which seems to feed well,” he adds. “There is some supplemental nuts too, fed in the pasture and when the cattle are inside.”

Cattle are purchased from a handful of selected farms, where relationships have been forged over quality, and at the end of the cycle they’re sold to some local farms to finish, avoiding market costs and transport hassles as well as animal stress.

“We’re looking to see if we can finish a few cattle on fodder beet, which we might look at growing if we can prove the theory, but the current cycle works,” says Rick.

This year the farm is scaling back their sheep numbers, the Texel crosses and Suffolk flock is roughly 650 strong currently.

“It’s a lot of work wintering them out, you have to be on top of the fencing on rented land, which takes time, and we have the cattle in over winter so don’t have the space inside,” points out Will.

300 is the future target, the sheep still provide an income and are great for cleaning up grazing pasture behind the cattle. The market for the lamb has changed somewhat, so there isn’t the same direct outlet for the animals. Previously local butchers were keen for lamb but have ceased trading, so sending to market is the outlet, reducing the motivation to push lambs.

Rick has been the driving force behind the flock, developing a good breeding system but decisions on the farm are made collectively, and running that head count is taking it’s toll on the time available.

Another string to the bow

Tractor and man work is also an element that Rick was originally behind. After leaving school he wanted to do more tractor work and add a chargeable service to the business. This was when the Case IH Maxxum 130 CVX arrived, a huge tractor for the farm at the time, it was mainly hauling silage in the summer that occupied the extra tractor.

As the years marched on and Will joined the business there was another wage to find, so expanding their contracting outfit seemed logical. In the early days this came in the shape of cattle and sheep haulage, the farm does still carry out some of this work, but at the peak they had a tractor clocking a thousand hours a year moving livestock.

“It’s not the work for everyone, and you need someone keen on that job,” says Rick. “As we got busier with other work it made sense to scale it back a bit, endless roadwork takes it’s toll on tractors.”

Originally the farm was McCormick users, which became CNH when Rick got the first contracting tractor, this switched to the blue arm of CNH with a run of New Hollands until recently. The farm bought a fixed chamber round baler in 2017, to do their own work using local contractor to come and wrap, since then everything has changed.

Colour change

“We were all New Holland at one point, we had a really good relationship with Malpas Tractors, and when they lost the franchise we started looking around for an alternative,” explains Will.

Going from one main tractor to two was a push, so hiring was a viable avenue. A T7.210 was the prime mover, with a T5 also hired in to take care of hauling bales. With the Malpas Tractors departure from New Holland this arrangement came to an end, and buying became an attractive route.

The main issue was the farm had a couple of sub-100hp tractors, not contracting machines, and nearly everything they bought was an addition, there was nothing to trade in to soften the blow. So, whatever was added had to earn its keep.

“That was when we looked at John Deere, we’d lost our favourite dealership, and there was a fully loaded ex-hire 6155R in at Cornthwaite Agricultural, so we gave it a try, everyone was sceptical including Rick, but we love the Deere’s now,” says Will.

The first John Deere landed in 2023, and the farm was running a New Holland T6.175, T6.180, a McCormick CX95, and the John Deere, all separate dealers, which was a headache so some streamlining was needed, and the switch to an all John Deere fleet started.

Contracting expansion

The business bought their first Kuhn FBP3135 baler in 2019, by their second season with one combi baler it made over 10,000 bales, and it was an exceptional growing season, so thoughts toward adding second baler started being discussed and another FBP3135 arrived for the 2021 season.

“We bought the combi baler to make life easier,” stated Will. “We had picked up a couple of contracting jobs with the round baler, and a combi started to make sense with the work we had, so the first one came from Malpas Tractors, it was quite an early model, and went very well, and brought in more work.”

Work was coming by word of mouth, and the Venables contracting business was starting to become a bit of a monster. The same was true in 2024 as was back in 2019, each step into expansion was buying a machine outright, so everything was carefully considered. And the next steps and how big the business was to become was thought about.

By 2024 there were three John Deere tractors, two 6R’s and a 6120M, there was still a New Holland in the fleet, which it was decided to be replaced with a tractor with loader, something handy that could also handle the Kuhn combi baler. A 6R150 fitted the bill, this purchase was softened because there was something to trade in.

The business is now quite bespoke in their grassland services, a third FBP3135 was added in June 2024 due to increasing workload, and between the three balers 22,000 bales were made last season. Demand for baling had grown to a point where two machines in a good season was enough, but 2024 was not a good season, and everything was under pressure, so adding the third baler and pushing the oldest to back up status seemed a logical step.

“We don’t want to get into chopping, or any other grass machines at the moment,” says Rick. “What we do is full service – if required – round baling, and that’s enough.”

This year also saw the addition of a new handler and a Bailey low loader with hydraulic beaver tail, this completes the full service baling line up, the low loader becomes a bale trailer, and the Merlo P27.6 can operate perfectly in tight yards and stacks.

“The handler was bought for the poultry sheds primarily, but it works well for stacking bales, it’s small and manoeuvrable, and we can comfortably stack three high,” points out Will.

An AW bale trailer with side rails is another tool in the bale clearing armoury. This speeds up hauling when there’s roading involved, securing bales is faster and safer and generally much easier than strapping them down. The business has also bought two new rakes this year, stepping away from Kuhn to try a Sip 850/26T which operates from 7.24m to 8.00m, and a wider working McHale with the idea they’ll have a rake for any crop conditions.

Outside of the baling operation, the two larger tractors are kept busy, either hauling potatoes for a local producer, or lugging a dump trailer shifting aggregate. Will says ideally they need to clock 1,500 to 1,800 hours a year to justify owning them.

Tenants on site

At the front of the farm the old buildings have slowly been converted, the first phase has been completed for a few years, and is now home to the large animal section of WM Farm Vets, they use the space for offices and a base for their vets who typically look after large farm animals and don’t need an on-site surgery.

As and when funds became available the buildings were developed, the vets units were made into blank rooms rather than a house type conversion, which will make the buildings easier to adjust if there is a change down the road. The last unit to be converted is Will’s house, which sees all of the original front yard converted.

Summary

J & J A Venables and Son have pushed their farm from a traditional holding, to a multi revenue stream agricultural business. They have avoided the specialise to succeed model some businesses are navigating and instead have put resilience as a priority by spreading their liabilities.

For more up-to-date farming news click here and subscribe now to profi and save.