One of the most striking things about Merlo is the large number of components that it manufactures on one site — not just taking in sheets of raw steel to be cut, bent and welded into a chassis or boom, but also creating its own hydraulic fittings, moulding plastics and developing electronics. We take a tour of the expanding site at Cuneo in north west Italy.

KEEPING IT BRIEF

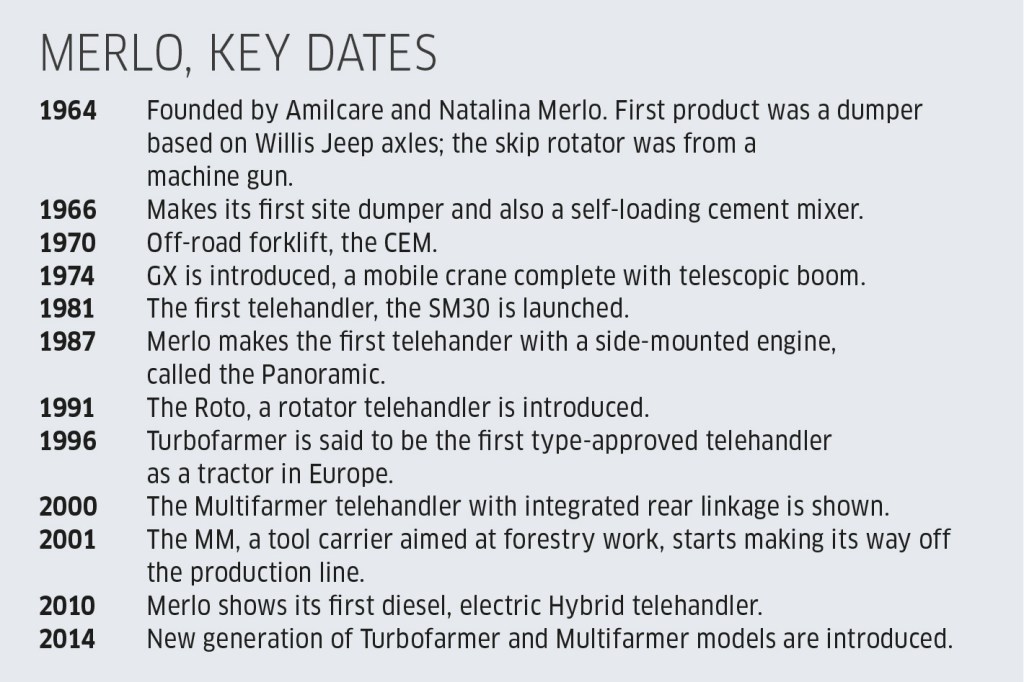

- Although Merlo has been in existence since 1911, the industrial business we know today was founded by Amilcare and his sister Natalina Merlo in 1964. Silvia, Paolo and Andrea are now in charge of the family business.

- Last year Merlo manufactured over 8,000 machines (around 6,800 of which are telehandlers), and it plans to do the same in 2025.

- As well as various types of telehandlers, Merlo currently manufactures waste compactors, self-propelled cement mixers and has recently returned to the dumper market that, incidentally, was the product it started making in 1966.

- A large number of components are made in house including transmissions and axles as well as electrics and hydraulic items.

- Italy accounts for about 16% of production. The big three export markets are France (18%), Germany (15%) and the UK (11%). Merlo claims a 14.2% share of the telehandler market in Europe, 9.0% worldwide.

- There are eight Merlo-owned subsidiaries around the world.

- Employs around 1,700 staff, a figure that has increased by over 20% since 2019.

The driving force behind Italy’s best known telehandler, Amilcare Merlo, may have passed away in 2022, but the family-owned business has not slowed down. Far from it. Rather than shrink, the firm is currently expanding its factory at Cuneo in north west Italy.

The Cuneo plant is where Merlo not only makes its telehandlers (both agricultural and construction) but also a range of attachments as well as the Cingo and Tremme tool carrier vehicles that are shipped around the world. Just a few kilometres away there is another Merlo factory that builds waste compactors. In all, the company produced around 8,000 machines last year (770 bin lorries and about 6,800 telehandlers) although the plan is to increase the overall figure to 10,000 in the coming years.

Actual manufacturing

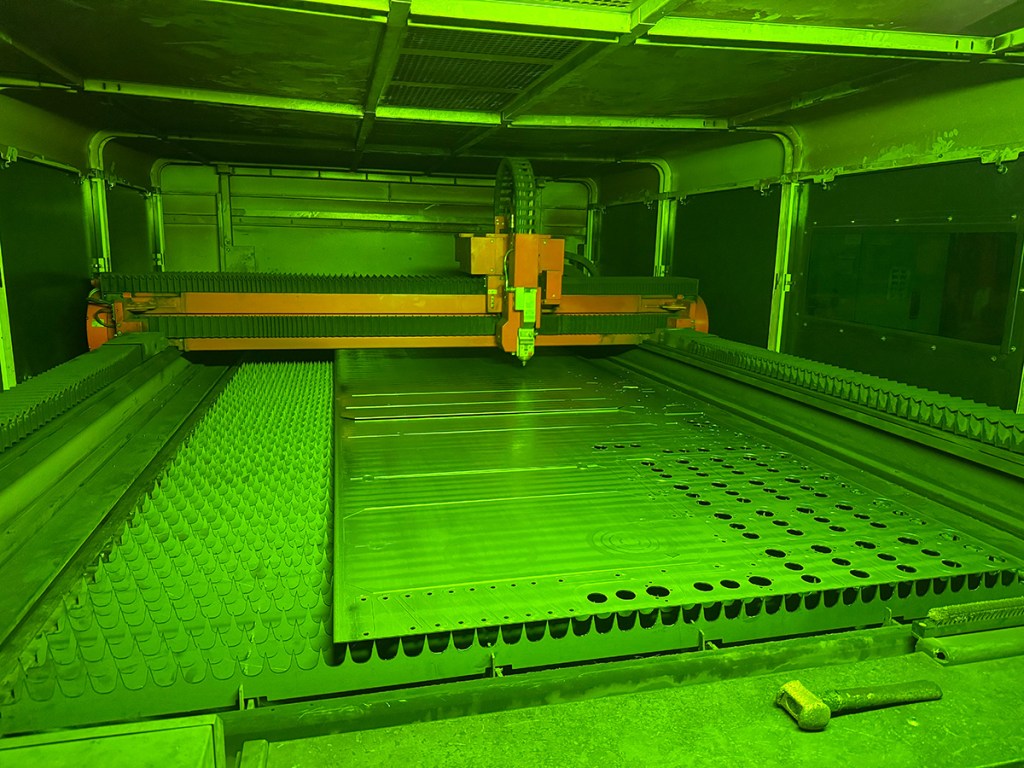

But Cuneo isn’t just an assembly line. Merlo reckons it manufactures around 92% of its needed components in-house; that includes the usual steel fabrication you would expect to find, and also hydraulic rams, gearboxes and axle production.

It has also started making its own plastic parts, which, when you think about the total amount of packaging and shipping involved in moving these lightweight components, is a big win in reducing waste.

Lastly, there’s the electronics division, with Merlo also developing its own telematics system on-site.

Marketing and communication manager at Merlo, Mattia Bodino, was our guide for the day. When he started with the company in 2006, Merlo employed 700 staff; today that number has grown to 1,700. “Ten years ago, there were no robots in the factory; today there are 25 robots.”

Not only are these machines carrying out welding and milling work but also loading the press brakes and taking away the folded steel components. And there were more robots being added to drive for greater efficiency and precision.

On top, and down below

On a clear day you can see the Alps from the factory, which is making the most of those clear days. The rooftops are adorned with solar panels, with another 840kWh added last year to bring the total to 2,240kWh. This will allow Merlo to produce a handy surplus of electricity.

But it is not just above ground that things are happening: there is around 18,000m2 of factory space below ground level (40,000m2 total). There is also a rail system for moving steel and parts, with a multi-level parts store used to hold items needed for the assembly line.

Spare parts for retail are stored in separate buildings: the first was built in 2015 and this was then doubled in 2020. Here there are over 40,000 spaces in the fully automated picking system, which has electric lifts that move along rails and pick from the 80,000 boxes. This system applies to around 90% of the parts, but anything bigger than 350kg or 1.0m in physical size is stored separately for manual handling.

As mentioned, work is already underway to expand the eight telehandler assembly lines. This will add more stations but means less work has to be done at each one, boosting overall output to help meet the demand for more Merlos.

Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.