The Case IH CS models have gained a cult following for their Austrian build quality and modern features. We take a look.

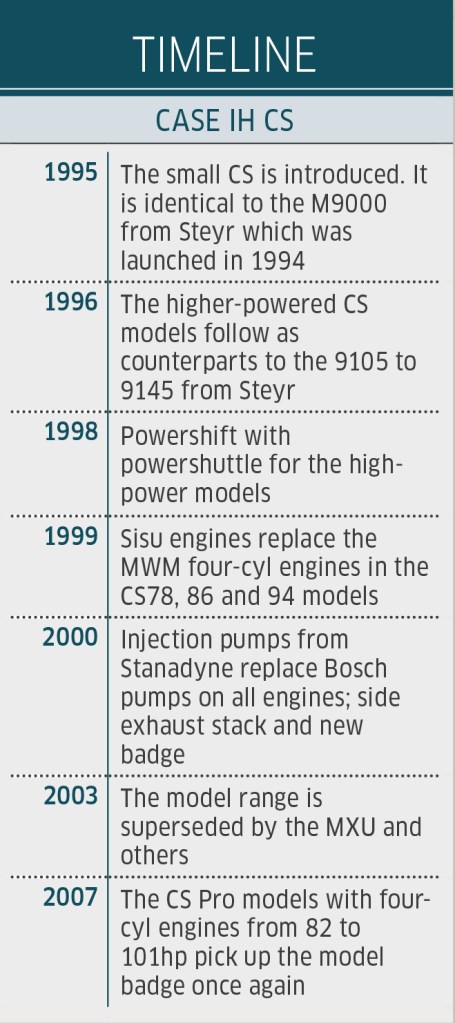

It was in 1996 when Case IH took over the Austrian tractor manufacturer Steyr. Soon afterwards, the CS was introduced, based on Steyr’s M9000 series and, equally fresh-faced, larger 9105 to 9145.

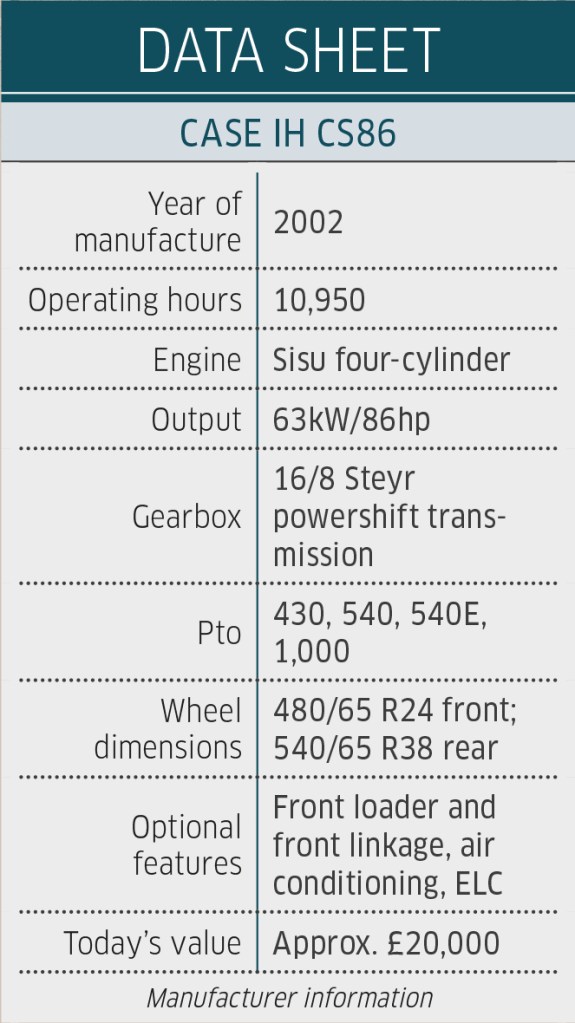

At the time, Steyr was largely focusing on three sizes of tractor. In Case IH lingo these were the CS Compact (35kW/48hp to 55kW/75hp) three-cylinder and the two ranges which we are focusing on here: the four mid-size CS models with a four-cylinder (57kW/78hp to 69kW/94hp) and the larger chassis four- and six-cylinder tractors (77kW/105hp to 107kW/145hp).

We spoke to workshop foreman Martin Jürgensmeier as well as apprentice Marian Hermelingmeier at German, Case IH dealer Neukirch in Delbrück, who both own a CS and know the advantages and the problems.

Martin Jürgensmeier bought his CS86 when it had 8,400 hours on the clock. It now has 10,950 hours on the clock. “I mainly use the tractor for forestry work and some winter maintenance for my side business,” says the workshop foreman.

The CS130 owned by apprentice Marian Hermelingmeier shows almost the same hours. “My father bought the tractor in 2013 with just 3,000 hours on the clock. Since then, it has been running up around 700 to 800 hours a year,” he explains. Its main tasks are loader work with a Stoll FZ50.1, but also some row-crop work and occasional arable jobs on the 160-hectare farm.

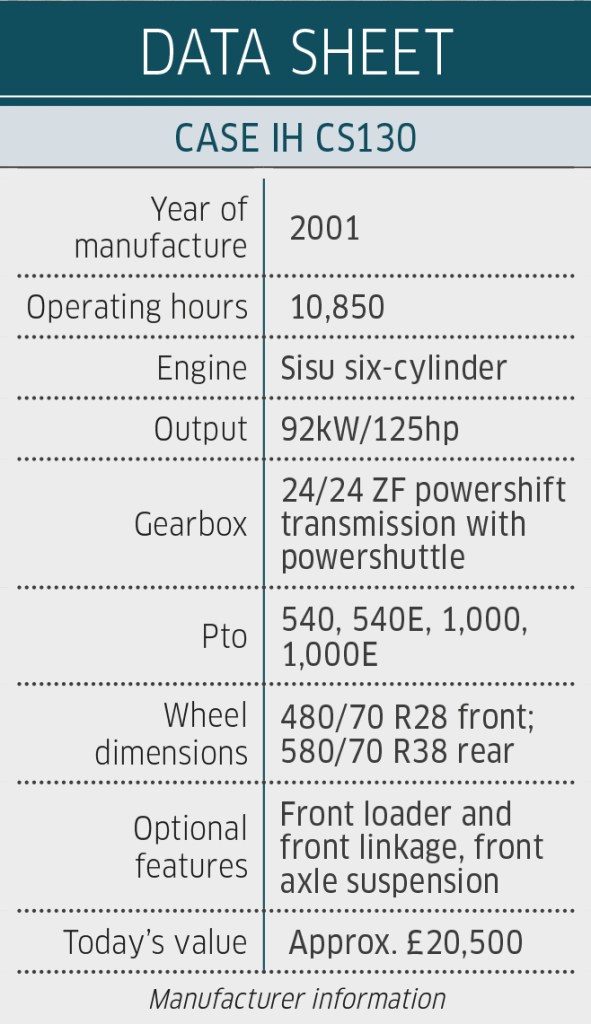

The CS models are popular loader tractors, as proven by the two models we look at here. “The sloping bonnet makes for good visibility,” reports Martin. The only thing that obstructs the view of a raised loader is the low roof lining, which explains why the roof was rotated on the CS130. “This allows me to look out the top, if necessary,” says Marian.

Robust engine choice

While the larger six-cylinder models draw their power from a 6.6-litre, Sisu engine, the smaller models were initially powered by four-pot MWM powerplants. The latter were considered vulnerable to overheating issues compared with the Sisu four-cylinder, 4.4-litre units that were installed from 1999 onwards.

Another change concerns the fuel injection system. Initially, all models had mechanically controlled in-line injector pumps from Bosch which were later replaced by distributor injection pumps from Stanadyne. The CS models are generally considered to be lively, although the CS110, as the only four-cyl machine on a large chassis, is sometimes a little sluggish, says Martin.

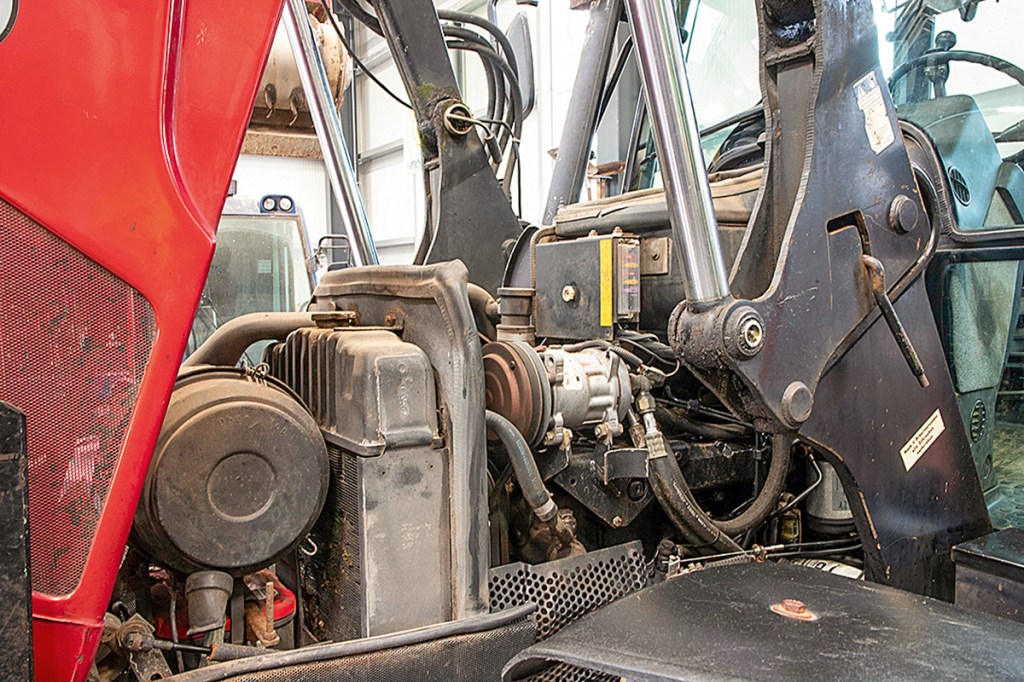

From 2000 onwards, Case IH improved the air supply to the six-cylinder engines with additional air vents in the sides of the bonnet. Otherwise, the radiator pack is pretty cramped due to the brand’s trademark sloping bonnet.

Another issue is the cold-start performance of the six-cyl engines, which explains the presence of a preheater or a larger starter motor on some machines.

Two powershift transmissions

The smaller models have the four-speed TW-557 from Steyr/ZF with a gear splitter and a reduction gear resulting in 16 forward /8 reverse speeds; the optional creeper box increases this number to 30/16 with 40km/hr being the maximum speed.

Changing direction is carried out from a second lever to the left of the gear lever. This takes a powerful step on the somewhat stiff clutch pedal. Indeed, you’re better off changing direction when stoodstill; otherwise the synchros can be damaged and need an expensive repair. If you are looking at one of these, then check the gear change.

Martin would have preferred one or two extra powershift steps, just like on the bigger CS tractors, which had a six-speed manual ZF 7200 series gearbox with four powershifts and a top speed of 50km/hr. The models built from June 1998 have an electro-hydraulic clutch instead of the mechanical-hydraulic unit.

At the same time, the powershuttle moved in under the steering wheel to the left and on the Multicontroller. On these machines, the direction of travel was preselected by pressing a button on the Multicontroller and then changed by stepping on the clutch — a solution that was very useful for loader jobs.

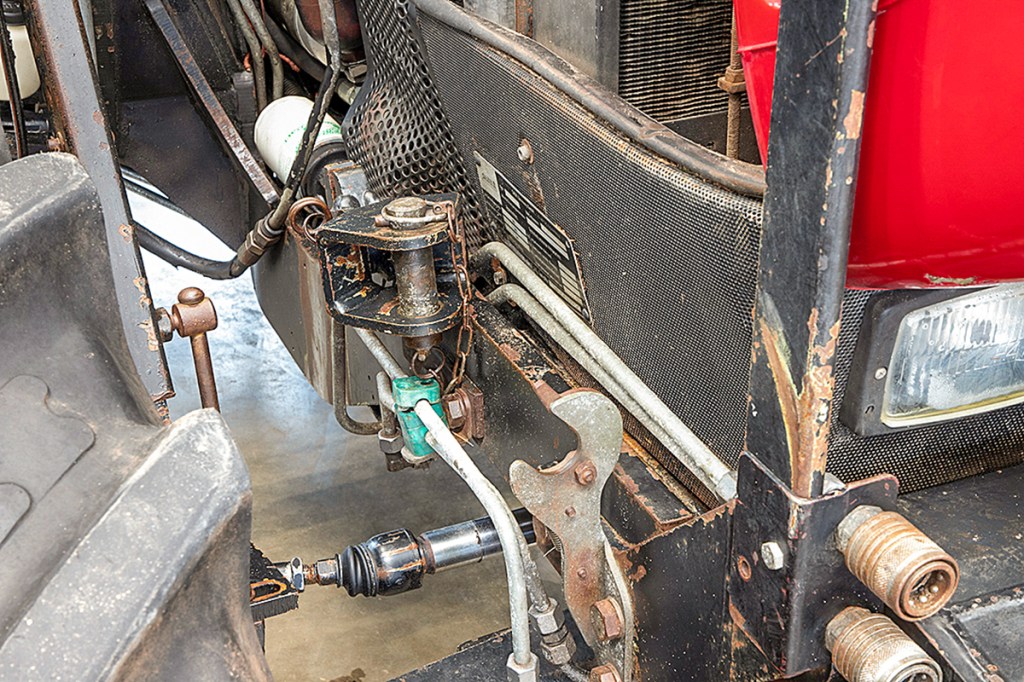

Any transmission issues on the larger CS models are often electrical, caused by faulty wiring harnesses or solenoids. Error codes can point you in the right direction for a fix, and there is plenty of room on the right- hand side of the box to access the solenoids. The service brake should also be checked: if there is too much travel and braking poor, you can adjust it. But if the brake discs are warped, they will need replacing.

All kinds of hydraulics

The small models have a tandem pump that supplies up to 50l/min flow for the remote services. A second pump was available as an option, delivering a further 46l/min.

Up to three mechanical spool valves and one electrical unit are available on the Pro model, which was marketed alongside the base Basic and Comfort versions.

The electric spool is operated from the Multicontroller on the main gear lever, which is available in the Pro configuration. Otherwise, there are only the powershift buttons on the gear lever.

All of the bigger CS models came with the Multicontroller stick. It is worth noting that there was often just one electric spool although there are two buttons on the stick. Only the top-end ‘Super Six’ version, which was debuted towards the end of production, usually has two electric spools.

The hydraulic pumps on the larger models also underwent changes. Two gear pumps with 80l/min each were initially used, one for the system pressure and transmission lubrication, the other for the remotes.

If you have a lot of hydraulic-demanding applications, then it is better to look for a later model with side-mounted stack. These usually have a load-sensing pump (115l/min). CS tractors with a fixed displacement pump, in particular, can be rather prone to overheating the hydraulic system if in continued operation.

A bit of comfort

At the time, Steyr’s new Multicontroller presented a real milestone, although it did take some mastering, to shift the powershift ranges — up from the left button and down from the right.

“But with a bit of skill, you can swap the buttons,” says Martin. The optional Carraro 20.25S front axle with fully independent suspension ensured extra comfort, although the option was only available on the four top models.

If you have one of these on your wish list, you should jack up the tractor in the middle of the axle and check the main pivots for play. When you are at it, raise the axle by pressing the button: if both ends raise in parallel, the spring rods are functional and the tension is fine. Defective housing caps also suggest damage.

The alternatives to the Carraro 20.25S front axle are the Steyr front axle on the small CS models and the unsprung Cararro axle on the larger models. On loader tractors, it is important to take a look at the swivel housing bearings. Further comfort features included an ELC linkage, which was standard on the larger models and an option on the smaller models, and air-con typically on the larger models. The smaller models have this fitted to the rear cab roof due to the limited space.

Summary and prices

That’s our whistlestop profi tour of the two main CS ranges you’re likely to come across. Either is a pretty solid workhorse with a nice sprinkling of comfort features such as the powershift. The smaller four-cylinder models are suited to smaller yards. If you need more features and performance, go for one of the larger models.

The price differences between the various power classes are not large. For a CS with only 5,000 to 8,000 hours on the clock, budget around £25,000 or more if there is a front loader. If you don’t mind something north of 10,000 hours, you’ll definitely find something in the teens.

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.