Although developments have been made to the original concept, any Spread-a-Bale model is designed to do exactly what the name suggests; spread straw primarily as a bedding material. Employing rotors to tease straw from a round or square bale and propel it without chopping or blowing. All Spread-a-Bale variants, regardless of age, can make a sound used buy but the trick is to know what model will match your needs and then find one.

KEEPING IT BRIEF

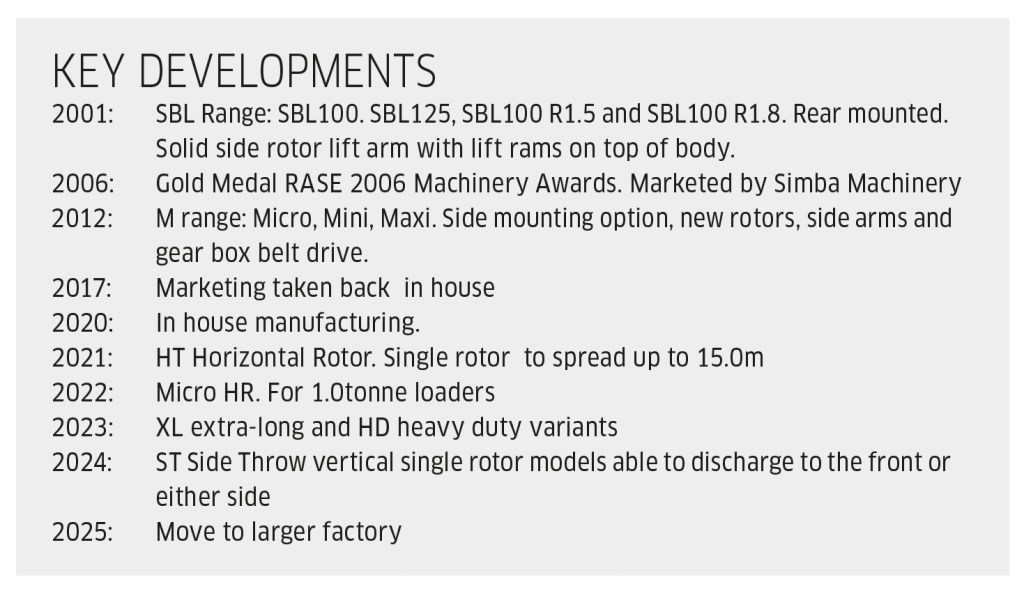

- Spread-a-Bale officially launched 2001. Sold through Simba machinery

- Design favoured for low dust littering

- Side mount kit can be retrofitted for horizontal spreading

- Manufacturing and marketing taken in house from 2017

- Midi 2VR the most popular variant in the UK

- Upcoming popular models – the Midi ST and Micro ST

Designed by Cheshire dairy farmer Michael Hughes, the first Spread-a-Bale saw the light of day back in 1999, with production twin-rotor SBL100 2VR models appearing a couple of years later. Designed to handle square bales of up to 1.20m x 0.90m or 1.5m round bales, a SBL100 2VR attaches to a front loader or telehandler, with the rotors spreading from the front. To load the bales, the rotors are raised on a frame so the spreader can be nosed into the bale, either at ground level or from a stack, the moving belt floor then reversed to help to draw it into the machine.

To spread the bale, the rotors are lowered, the moving floor engaged to push the bale into the rotor spreading vanes. Both floor and rotors are hydraulically driven, with no in-cab control box needed. Everything is controlled via a valve manifold linked to the third service in the loader or tractor. All Spread-a-Bale models essentially work to the same basic principles, sticking to the key design principle of ‘keeping it simple’.

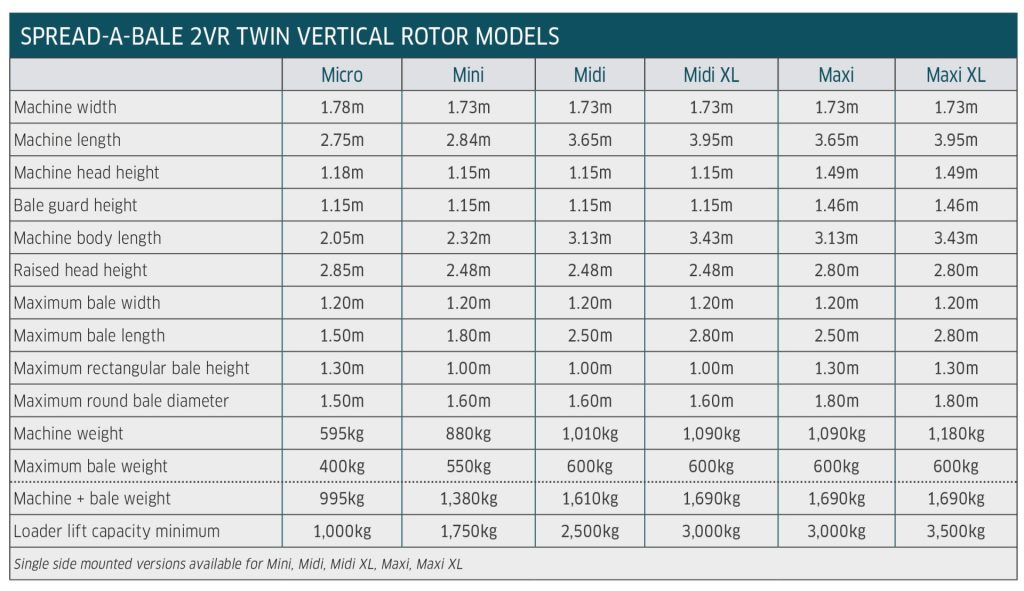

To reflect the increased lift capacity of telehandlers on farm, the Spread-a-Bale offering was increased to include the longer SBL125. These models were given a name update; Midi replacing the SBL100 and Maxi the SBL125. The latter is essentially a longer version of the Midi to suit handlers with a 3.0t plus lift capacity. The larger models will handle bales of different shapes and size including rounds up to 1.80m diameter and square bales up to 2.50m in XL form. You can spot a Maxi by its taller 1.30m rotors, while an XL is 300mm longer.

For lower capacity loaders/handlers, the range was expanded to include the Mini 2VR for loaders of 1.75t plus. These are shorter machines and better suited to use in more confined spaces. A Mini is compatible with round bales up to 1.60m and squares of 1.00m to 1.80m.

Completing the range is the Micro model launched in 2022. This will suit loaders with a nominal 1.0t capacity and will spread a single round or half rectangular large bale (see outline specifications tables).

Other variations

Spread-a-Bale manufacturing and marketing was initially outsourced, the company moving things in-house from 2017. Changes included the introduction of two new heads to offer further straw spreading patterns. First up is the single HR Horizontal Rotor introduced in 2021. This will spread straw up to 15m in a longitudinal pattern. This was followed by the ST Side Throw variant in 2023. This is the specifically designed for narrow 2.00m wide doorways and passageways and will throw straw up to 9.00m to the left, right and front.

It follows that these newer combinations provide users with the opportunity to choose a body and rotor combination to suit their handler and desired spread pattern. As a used buyer, however, the most likely find will be the popular twin vertical rotor Midi 2VR. These models mount longitudinally as standard but may also be run horizontally when the apropriate attachments points are fitted. Retrofit kits for the latter are available, with some specifying both attachments points when new.

What to look for

When looking over a used Spread-a-Bale of any description, it is easiest to divide your checks to cover body, rotors and motors, bed and hydraulics. It follows that it is best to look over a machine hooked up to a loader so you can run it up. If this is not possible, the chances are you can still make a relatively low risk assessment of the machines ability to do the job as any repairs are typically straightforward. These are farm workshop friendly attachments and all the parts you may need to fix up even an old and well-worn model are available. Just keep an eye on costs. It can be more cost effective to buy a machine that is ‘ready to go’.

Main body

Original finish on early models can suffer, with flakes of paint sometimes peeling off. From 2012, Spread-a-Bale offered a galvanised finish that lasts well with no corrosion problems. This finish is popular although the rotor support frame on current models is painted unless this element is also galvanised as a further option. This is due to the galvanised finish on these parts not matching to the rest of the body which can ‘spoil’ the look of the machine.

Regardless of finish, the body of all models is unlikely to suffer structurally through corrosion. The body may fracture on heavily used models around the rotor arm pivot holes, but this is not common. If there are cracks, they can be weld repaired. The rotor frame support lug rests on the body side rails and this can lead to the latter sinking and even cracking on a well-used machine. This is a good wear indicator. Damage here is easy to fix.

At the rotor end of the body, look at the lower lip. This will run on the ground when loading and is a common wear area. Spread-a-Bale can supply a weld on lip to replace worn metal, but a simple steel plate repair will do the job just as well. Also check for wear in the side body to lip seam as this can also need attention.

NOTE: Take care when welding galvanised steel as it can produce noxious fumes.

Rotors and motors

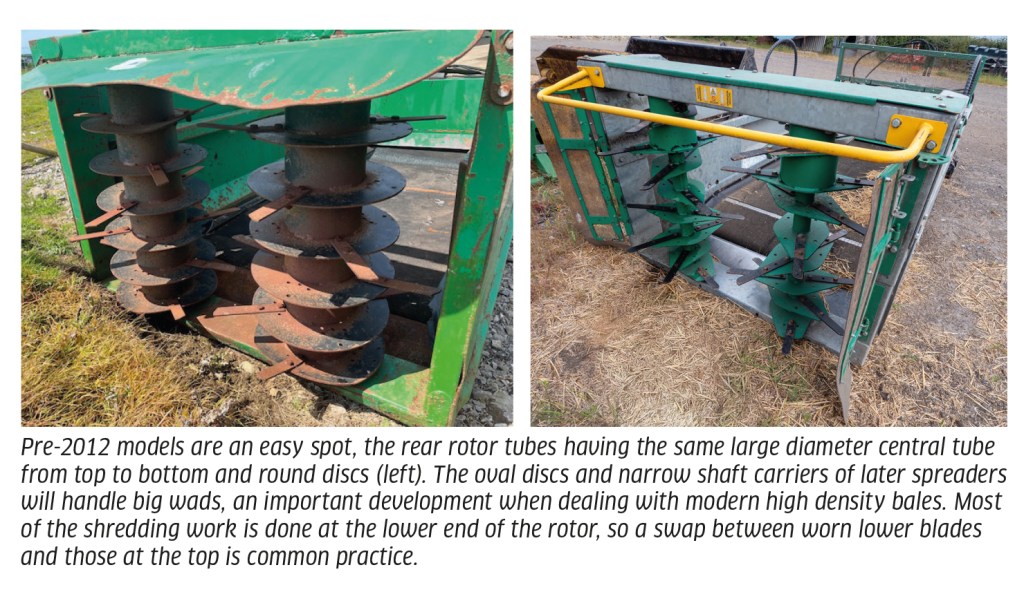

The original models have a wide rotor cylinder and circular disc to which the blunt straw teasing blades are fitted. This design was changed in around 2012 to the current slim central shaft for all but the top two discs. The discs themselves also changed to an oval shape. The later design is claimed to be less liable to blockages, although the latter are uncommon, and improved ability to handle heavy wads of straw. Any blockages can be released by reversing the rotors and bed drive.

The lower rotor bearings have grease points, regular lubrication typically ensuring these can last for the life of the machine. It is easy to detect any play by simply giving the rotor a tug. The rotors are individually driven by a hydraulic motor. Adan hydraulic motors are not known for trouble, but the seals can leak through age hardening or wear. A replacement seal kit is around £80 and can be carried out with care in a farm workshop. Swapping to a new motor is easy if the job is carried out according to the makers instructions, with a new unit costing under £500. If the rotor assembly is damaged or has significant wear in the bearings, the complete unit can also be replaced. It is for these reasons that even a well-worn Spread-a-Bale can command a strong used price as it is possible to refurbish it. Be mindful of costs as these will obviously increase if several parts need to be renewed.

Key rotor checks include looking for play in the bearings and checking for leaks. The blades can last for thousands of bales, swapping rounded tip lower blades for the those at the top of the rotor helping to peg replacement costs. The latter have a much-reduced rate of wear. Bent blades can be removed and straightened.

Belt bed

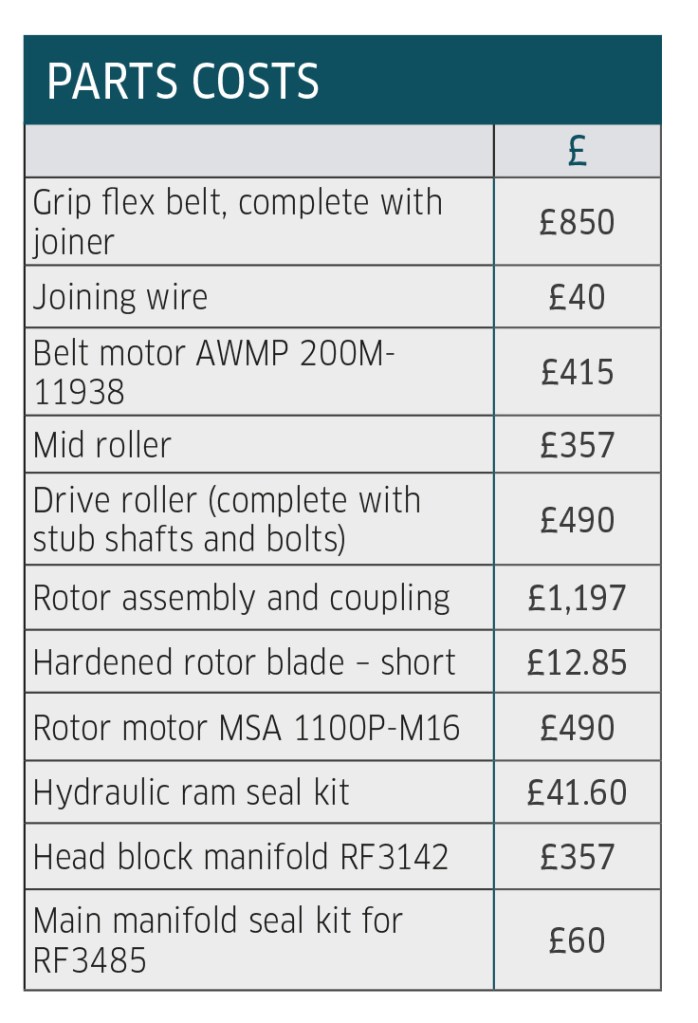

The bed belt is set to reverse to load a bale, with a much reduced feed speed when in operation. A direct hydraulic motor drive was used on the original models. This works fine but it required an underworked 200cc motor to do the job, the latter turning at a leisurely speed that was not best suited to running the belt at a really low speed. In 2012, the motor size was reduced to 50cc, with a reduction gearbox taking power to the belt drive roller. This increases torque to the roller and cuts the strain on the drive motor.

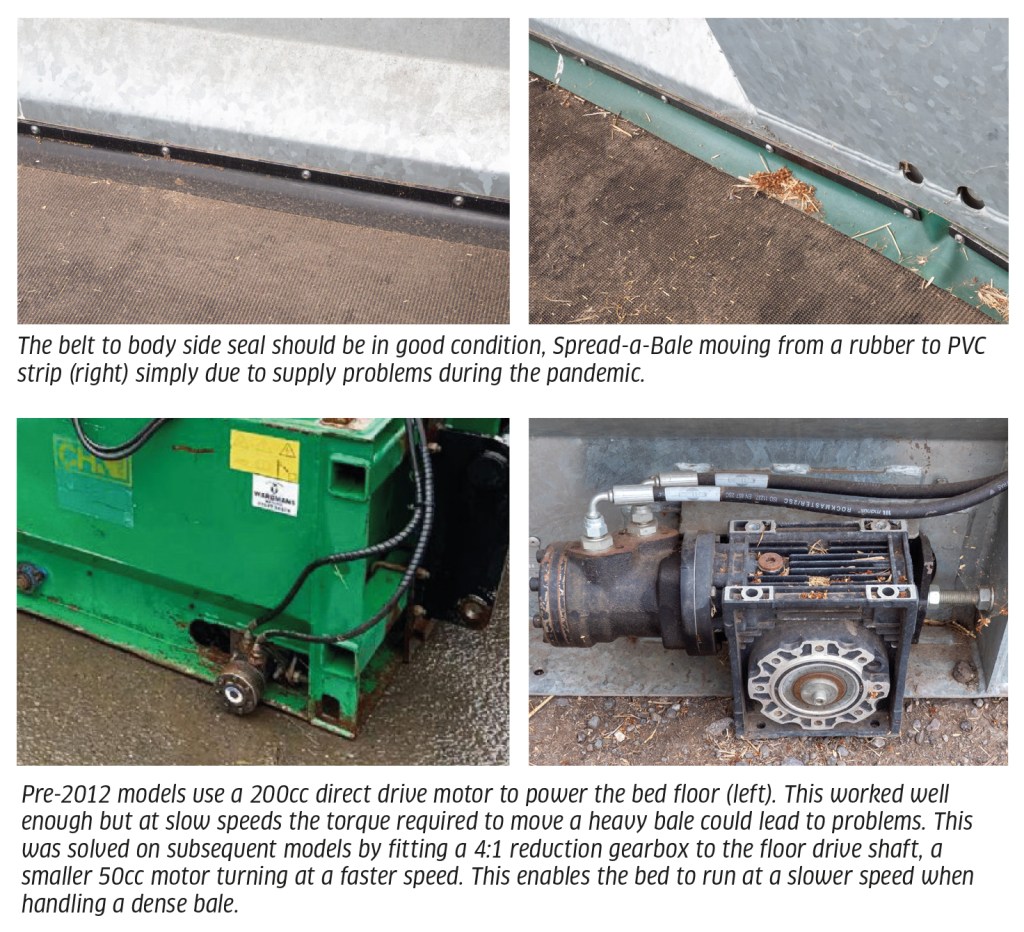

Despite this change, if the belt drive works when run up the chances are the system is just fine. As to the belt, it runs at a slow speed. This means a belt with a big longitudinal rip, such as may be caused by running over a stone when loading, may have little or no impact on the belts ability to do the job. If the belt is running slack it is tightened via a pair of tensioners at the rotor end. Mid-rollers support the belt, these having greaseable bearings that can last the life of the machine if lubricated periodically.

Hydraulics

On the very first Spread-a-Bale models, it was necessary to juggle with separate controls to load the machine and then set it into work. A single sequencing valve block, fed by just a flow and return third service, has been fitted to all models since 2012, with the same design used on all models to date. There are setting valves that enable the user to determine the speed of the rotors and bed floor, with these typically being left well alone unless the attachment is used with a different handler with a higher or lower rate of oil flow.

A second manifold directs oil to the rotor motors and floor motor. Simple and designed to be repairable, these blocks do age, so check for weeping seals and blockages. There is a ‘pepper pot’ valve at the base of the head block sequencing valve that can block and the large proportional valve on the top may need new seals or swapping from the standard 55 litre unit to a high flow 90 litre alternative to suit a more powerful telehandler with high oil flow. The flow rate is stamped on one of the flats of the valve’s hex bolt head.

The sequencing valve will either work or need attention which is a good reason hook up and operate the Spread-a-Bale. Problems are rare but a new block is priced under £360.

The rotor frame lift ram seals may need replacing on a well-worked machine, a simple enough job with a sealing kit costing around £42. The rams do not work hard but check the pivot points for wear. Also make sure the hose couplings are in good shape.

Is that it?

Regardless of model, a Spread-a-Bale is a simple bit of kit, with little to go wrong. If there is a problem, most can be resolved in a farm workshop. It also follows that the bigger the model the more likely it will have suffered damage. Bashed guards and failed spreader plate securing pins are all par for the course. The key is to ensure the machine is structurally sound, with any cracks in the side rails, which are not common, having a good repair.

The main used buying point is to secure the right model for your straw spreading needs. It also follows that modern balers produce a heavier and denser bale. Consider this when looking over an older model as these will have been built to spread what are now considered to be lighter bales. The best built units are those made in-house from 2017, with those made from around 2021 representing the best buy if you can find a used example.

With thanks to Dave Bull, Spread-a-Bale, Matt Kennedy, Oliver Agriculture Ltd, Wardmans (Matlock) Ltd and Keith Twentyman, Cumbria.

WHAT ABOUT PRICES?

Early models can command between £2,000 to £3,000 if in good order but these units are now becoming a rarer used find; most will have just been worked to the point of no return. Post 2012 examples with, regardless of size and model, may start at prices from around £6,000 but you can pay more for any unit that has been dealer fettled and is on tip-top order.

VARIATIONS GIVE WIDE CHOICE…

…but not all will be available as a used buy. Although it is the Midi HR twin vertical rotor model that will make up the bulk of used finds, other variants as listed in the outline specification table will suit different bales sizes. There are other variations including:

- HR horizontal rotor. These models will spread to the front at 1.0m to 2.0m width with a forward through of between 8m and 15m. Offered in Micro, Mini and Midi body sizes.

- ST side throw. Latest addition to the Spread-a-Bale range with single vertical rotor with spread canopy adjusting to enable material an 0.8m band of straw to be spread to either side or directly ahead at up to 8.0m. Offered in Micro, Mini, Midi, Midi XL and Maxi XL body sizes.

- HD heavy duty. Fitted with more powerful rotor motors with a 19% increase in torque. Taller 1.30m rotors designed to tease straw from highly compacted bales.

- HF high flow. Revised hydraulic manifold and pipes to increase oil flow by up to 27%. To suit high capacity handlers.

- Feed-a-Bale attachment. Used to break up a bale to be fed into a mixer wagon.

- AD avian deflector. Vertical deflector for use with VR models to enhance straw spread width and reduce spread depth for use in poultry units.

BALE HANDLING BASICS

In terms of length, Mini models can accommodate a square bale of up to 1.80m or one round bale, the popular Midi a full length 2.5m square bale, longer Maxi models a 2.80m square or two round bales.

As to width and depth, Mini and Midi rotor heads are capable of processing up to 1.20m x 0.90m square or 1.5m round bales, larger Maxi heads dealing processing square bales of 1.20m x 1.20m or round bales of up to 1.80m in diameter.

DENSE BALES, POWERFUL HYDRAULICS

Bale densities and weights have increased over the past 20 plus years, as has the available hydraulic muscle to drive attachments. As a used buyer, the chances are that the Spread-a-Bale models on offer will include early models that were built to match the bales and handlers of the time. Pop a 2002 SBL100 onto the front of a 145hp telehandler with 110litres/min flow and a dense 600kg bale to spread and the by now 23 year old machine made need a bit of care to avoid overloading the hydraulics. Switch to a current HD model with HF high flow hydraulics and the same bale will be dismissed with ease.

A Spread-a-Bale of any type is a simple machine but it is not the same as saying all generations of machine are the same, despite several core parts having been carried over. The popular Midi can make a sound used buy but do not just assume a model of any vintage will match your bales and handling equipment.

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.