Case IH owners have been busy sharing their tips for Puma perfection and Maxxum magnificence, as well as offering a dash of original CVX class, with a range of mods that may also appeal to New Holland T6 and T7 owners.

Here we have a selection of major and minor tuning tips for Case IH Maxxum and Puma tractors. We’re always fascinated by the creativity of farmers and contractors in finding novel solutions that make daily chores easier. Here we feature a number of those clever ideas, many of which require only a few basic tools to create and install. It’s time very well spent in our view.

Alexander Bertling

EXTRA DISPLAY MOUNT

This owner installed a bracket for mounting an additional ISObus screen on the right-hand A-post of his Puma and Maxxum. Two M10 threaded holes are hidden behind the plastic trim for this very job. The position provides an ideal view of the display.

TURNED LIGHTS

On this Maxxum CVX, the brackets for the lights on the cab grab rails were rotated 180º. This provides much better protection for the lights than the previous position, and the owner also prefers the way they look.

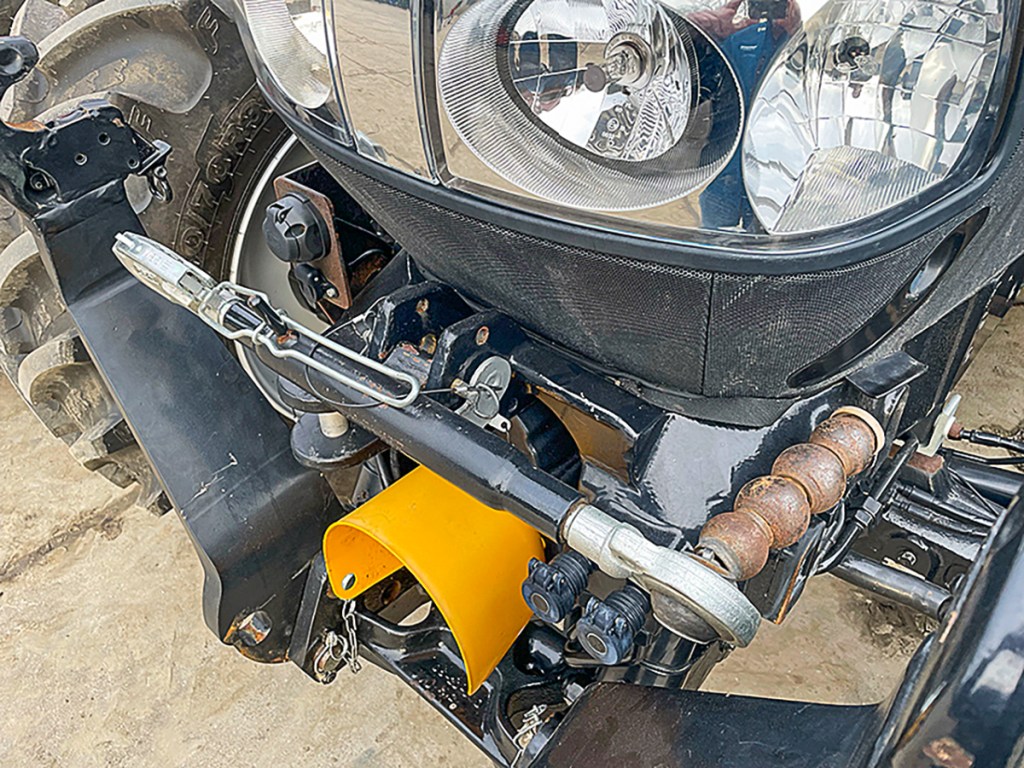

OPTICS AND ACOUSTICS

This reader installed two original Michelin men on the left and right of the headlight brackets on his Puma. They are complemented by a pair of air horns on the roof that provide an unmistakable sound. The horns are connected to the tractor’s compressed air system using 5mm plastic pipes. A switch-operated solenoid then releases the pressure to the horns. No danger of not hearing this tractor thundering around the bend.

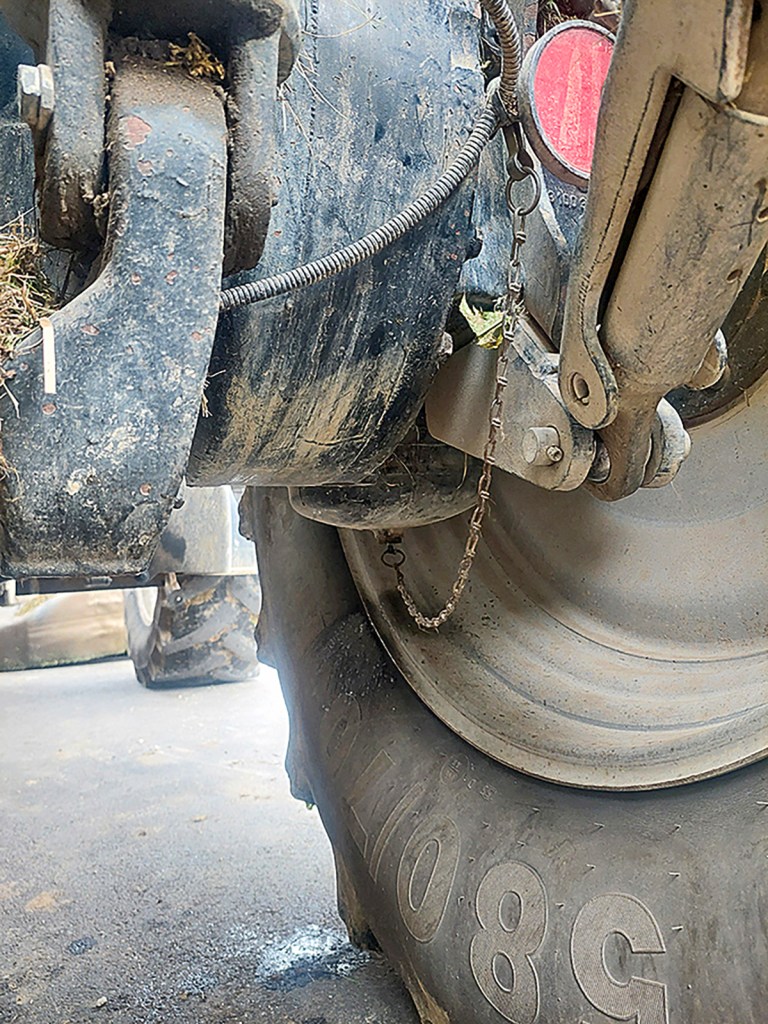

QUICK, CLEAN AIR DRAIN

By adding a chain to the drain valve on the air tank of his Tier 1 CVX, Johan Vogel no longer has to crawl underneath or squeeze between the lift arm and wheel, making this routine maintenance chore a much cleaner and pleasanter task.

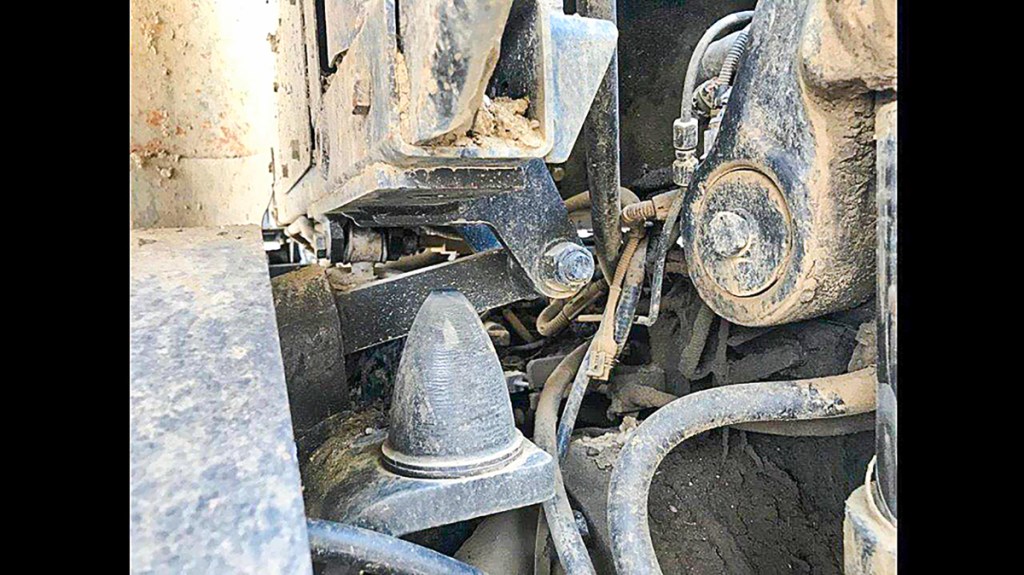

INCREASED SPRING TRAVEL

The original cab suspension sometimes had just 10-30mm of travel (with the driver onboard). Whenever the tractor hit a sizeable bump, the cab would hit the stops. To overcome this, Robert and Jakob Schöggl designed and fabricated a customised mount for the shocks. This raised the cab by just about 30mm — enough to significantly increase operator comfort. So far, they have converted several New Holland T6000 tractors (identical to the Maxxum 110-140 MC models).

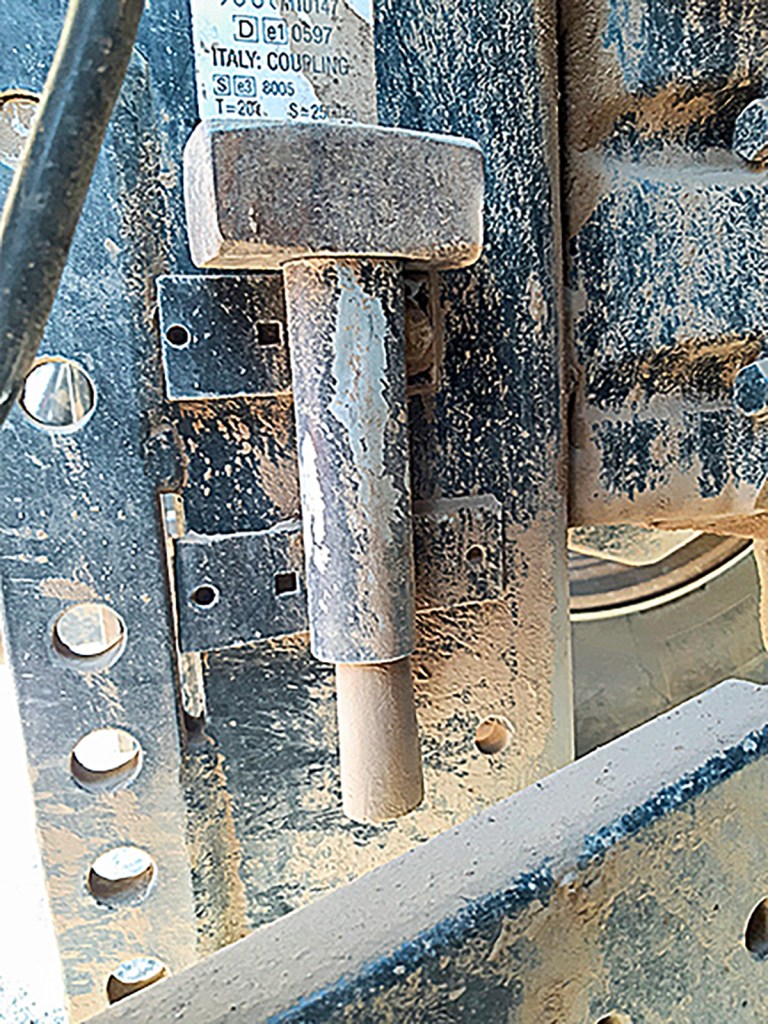

BONNET OPENS QUICKLY

This modified R-clip is used to press open the Puma’s bonnet latch. One end of the clip was cut short to provide the relevant pushing rod. The R-clip is secured on a chain at the front of the tractor so it’s always nearby and ready to use.

ROUND IS BETTER THAN SQUARE

The genuine ‘Baler bar’ mounting bracket is fabricated from rectangular box. This restricts where you can mont additional screens and control boxes. Robert and Jakob have made their own mounting bar from round tube and then used the original threaded holes in the cab to fasten it to. Pipe clamps then give you a lot more freedom and flexibility on where you can add screens and other accessories.

Pimped stabilisers

Instead of chains, spacers are used to switch between rigid and floating position on the lower link stabilisers. When the spacers are on top of the claw, they are locked. When under the claw, they keep the claw in its open position.

On the button

The dimple button on the armrest is not the most operator-friendly solution for engaging auto-steer. A second button on the back of the joystick seemed a more practical solution.

DEEPER STEPS

The depth of the steps on this tractor were increased to give a safer footing; there is now room for the entire foot. Scraping your boots is also more effective, keeping the cab clean.

GPS HARNESS EXTENSIONS

In order to be able to measure landmarks with pinpoint accuracy, Josef Steininger equipped his GPS antenna with an extension to the wiring harness. This allows him to remove the antenna from the roof and place it on a boundary stone, for example. The extra wiring is secured to the cab’s A-post with carbine hooks.

IMPLEMENT AND TOOL HOLDERS

Josef Steininger also fitted a spade holder on the left-hand side between the toolbox and the handrail. Made from flat steel, the holder allows the user to remove the implement with one hand. And as the handle is hidden by the A-post, it doesn’t impair the driver’s view. He also fitted a number of tubes to store a selection of tools, including a hammer and a wrench.

POWER STRIP

The connectors for the preheater for the engine coolant and for the hydraulic oil are under the cab door on the left. A Nato socket for charging the battery has also been installed.

ADDITIONAL PRESSURE GAUGE

An additional analogue gauge allows you to see the air brake pressure at any time rather than finding it on the A-pillar display or armrest screen.

HOLDER FOR THE STABILISER CHAIN

Since the brackets for holding the stabiliser chain were not up to the task, new ones were made. New brackets in place, the chain is now mounted directly above the stabiliser, allowing it to open and closer more easily. In addition, both linkage ball holders are now on the left side of the cab frame, as this is the side from where you typically couple up the machines.

OPTIMISED MAXXUM

EXTENDED MUDGUARD

The mudguards on the larger 42-inch rear tyres and 30-inch front tyres were extended with rubber mats to keep the tractor cleaner.

HANDLE INSTEAD OF KNOB

There is a knob on the left handrail that allows the operator to pull the door shut while seated. Adrian van den Hoek found this too far away and required too much effort so he added a stainless steel handle that is positioned closer to the operator.

KNEE PADS

Depending on how tall you are, some will smack their knee on the armrest. A piece of foam glued to the plastic gives you at least a bit of cushioning.

REARRANGED

This cab has been given a bit of a rejig. The AFS 700 terminal, which was on the armrest, has been relocated to behind the steering wheel. This made it possible to fit the Raven display on the end of the armrest where it falls easier to hand for altering any ISObus and auto-steer settings. The Aux-N joystick has also found a home on the armrest.

HORIZONTAL TOP LINK

A tab was welded to the front top link so it can be secured horizontally by the same pin used to hold it upright. The top link is now not in the way when opening the bonnet, and it doesn’t stick out, either.

PERMANENTLY ROTATABLE

To prevent the driver’s seat from immediately locking into place after swivelling, the lever can be fixed in its top position with a small bolt latch.

For more up-to-date farming news click here and subscribe now to profi and save.