Clamp compactors are becoming more commonplace, and not just for maize silage. Düvelsdorf is one of the newer faces and proved to us that there are still ways of standing out from the crowd.

KEEPING IT BRIEF

- When using a compactor, the rolling tractor can get across the job quickly and still do a thorough job.

- The arm-mounted tyres produce firm, uniform edges.

- Distributed in the UK and Ireland through Lynx Engineering.

If you are going to the effort of adding a rolling tractor to the clamp, then you may as well tool it up for the job in hand. Extra ballast is one thing, but then a clamp roller notches up the consolidation job to another level, allowing the tractor to get across the clamp top in an efficient manner.

Last year we tested the latest offering from Düvelsdorf, the aptly named Silage Roller, which has both side-shifting and over-edge rollers. Our steed for the clamping job was a Claas Axion 870 which was fitted with one dual wheel (320/105 R54) on just the right when working on grass clamps and the left dual was added when we got on to the maize harvest. The tractor’s front linkage looked after spreading and pushing. Overall, this rig weighed in at a healthy 15t.

The majority of the test season’s work was the handling of chopped forage in drive-over clamps without walls, which is why our test Silage Roller was equipped with the wheel kit for rolling the sides on both the left- and right-hand side of the machine.

High base weight

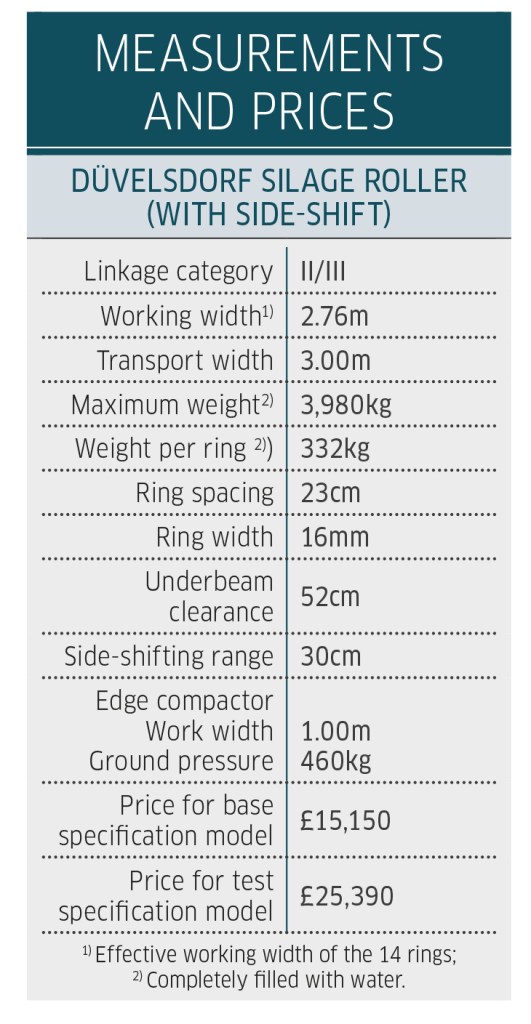

In its basic configuration, the side-shifting Silage Roller weighs just under 2,000kg, while the two edge rollers each add 385kg. Our machine also came with the rear towing arm, so base weight was closer to 2,900kg. Filling the drum of the roller with up to 1,000 litres of water brings the weight to almost 4.0t.

Hitching up is done via Cat II or III couplers. These sturdy lower link couplers have three different hole height settings for optimal matching up with the tractor.

Each of the hydraulic functions (side-shift, the two side rollers and towing arm) require a double-acting spool. So, for us that meant four double-acting spools. Alternatively, an electric diverter is available for switching between the two side rollers for £440. There is also the point that very few UK and Irish farms — unlike in Germany — have drive-over clamps, and this would negate the need for the towing arm.

The roller is parked on one stand front and rear. LED lights are standard fitment.

To the left, to the right

The side-shift on the main frame is protected by a plastic guide, making it maintenance-free.

There is about 30cm of travel to either side, allowing the roller to extend beyond the tractor wheels — although, to be fair, other manufacturers do provide more side-shift travel. Four plastic guide rollers prevent the steel frame from making direct contact with the walls — great.

The inner tube diameter on the Düvelsdorf is 107cm. This is fitted with twelve rings with a ridge height of 17.5cm and a thickness of 16mm. A notable feature here is the wavy profile of the rings, which is reckoned to reduce the amount of material that is flicked up and loosened again — something that seems to work well. Even with the grass containing a good amount of sugar, the roller stayed clean. As well as silage from a forager, we also packed grass from forage wagons and higher dry matter grass, none of which caused any problems.

Large wheels for stable edges

Each side arm carries two large 500/50 R17 wheels for rolling the sides of the pit. This gives them a working width of over 1.0m on either side. An excellent detail is that the gap between the two tyres is closed so they do not clog with silage. The advantage of the significantly larger diameter tyres compared to other makes is that the rolling action is smooth, so the forage is not picked up or bulldozed by the wheels.

A disadvantage, however, is the visibility when the arm is folded up, especially with the machine shifted fully to the left or right. We just unfolded the arms slightly while reversing so we could get a better view of what was behind us.

We really liked the high downforce, which according to Düvelsdorf is 5,250N. On the weighbridge, we measured an effective pressure of 460kg per arm — very good. The maximum pressure can also be adjusted using a pressure relief valve (or if you spend an extra £800, by using a potentiometer in the cab).

Whether the left-hand arm is required is something for you to decide, as it’s used less often than the right-hand arm. Not having it, knocks more than £4,100 off the price.

Pull up safely

The towing arm also scored good marks. This consists of a wire rope on an arm, which is centred both vertically and horizontally by springs. A double-acting spool is used to lower the rope onto the carting tractor hook. Düvelsdorf can supply the matching hook in packs of two for £290.

Summary

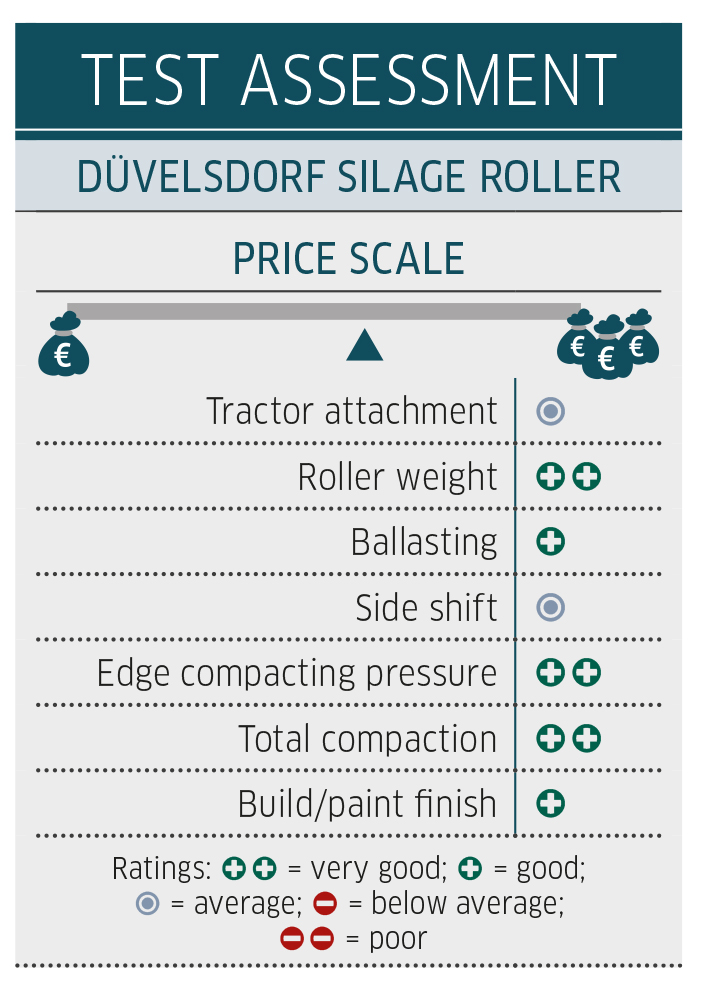

The Silage Roller is a useful tool when it comes to compacting faster. With the tested side-shifting model, Düvelsdorf now offers a well-built machine that works very well. The side arms with their large wheels did a particularly impressive job on the edges. In full spec, our test Silage Roller with the left and right side rollers, plus the towing arm, came to £25,390.

Jan-Martin Küper

For more up-to-date farming news click here and subscribe now to profi and save.