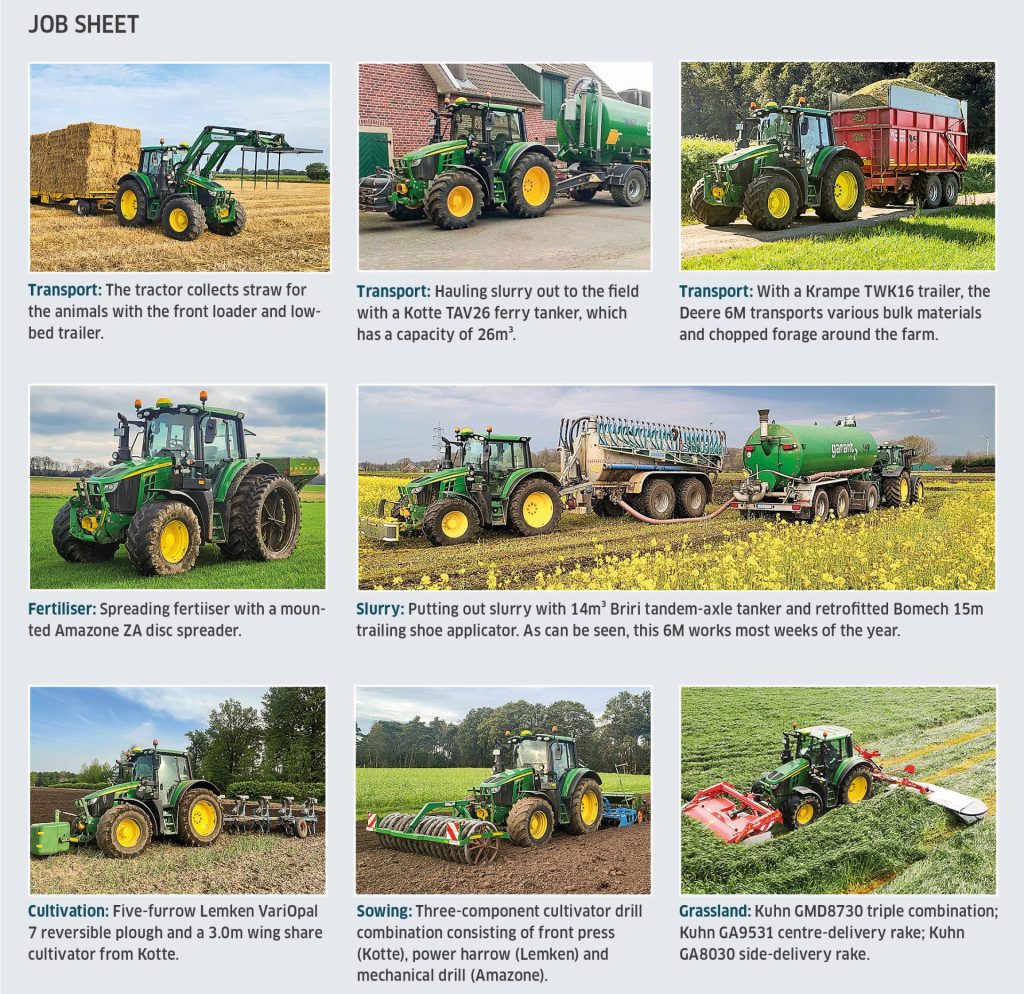

The 6120M with its sloping bonnet and 120hp rated output is proving an ideal loader tractor. Our long-term candidate doesn’t just have to take a load from A to B, but it has a healthy list of field and transport duties that it needs to be on top of, too.

KEEPING IT BRIEF

- For three years, the 6120M has carried out numerous tasks on the dairy farm it calls home.

- With the exception of a hydraulic pump, the repair log doesn’t look out of the ordinary.

- The engine, transmission and dimensions get the owner thumbs- up, while the small diesel tank and the limited number of spools are criticised.

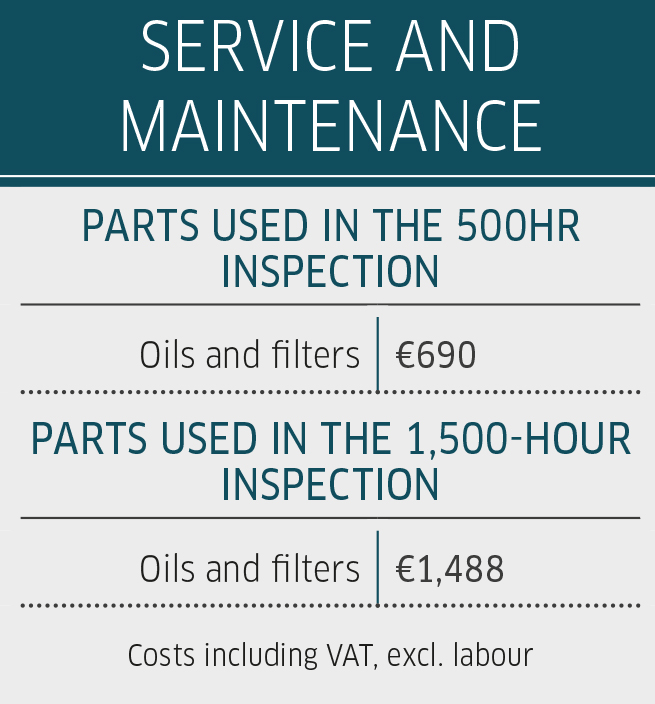

In just over three years, our featured long- termer 6120M has toiled its way to 4,657 hours, not only filling the tub mixer but also doing its share of fieldwork with machines that are anything but light loads. Impressively, the tool list includes a Kuhn plain triple mower combi with a working width of 8.70 metres.

The owner is extremely satisfied with his 6M’s performance. The engine is both lively and quiet. The other four tractors on the dairy farm are also four-cylinder models. “We remain true to ourselves in this matter,” points out the 6M’s owner with his buying strategy, so it’s no surprise that a 6R150 is now on order.

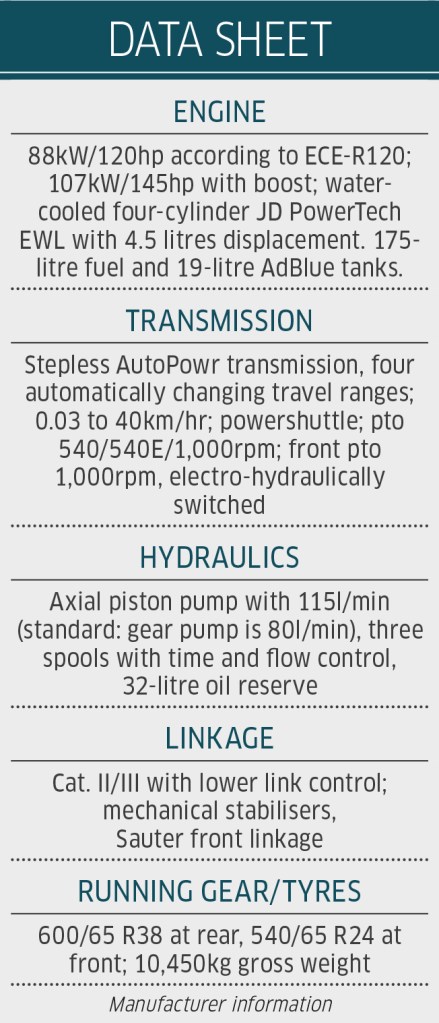

The 4.5-litre John Deere motor within the 6120M impresses with its smooth running and fast power delivery. The fact that the throttle valve on the turbo was leaking and causing whistling noises was fixed by the dealer as a gesture of goodwill, when they repaired the hydraulic pump at 3,182 hours, impressed the owner, too.

Lots of power, limited cooling

During heavy draft and pto work, the small Deere can easily guzzle 30l/hour out of the tank. While the owner doesn’t criticise its fuel consumption, he is not happy with the tank size. It only holds 175 litres, although 205 litres would be possible as an option. This means that on power demanding jobs, such as operating the triple mowers, they need to tip back to the yard at least once to refuel — even the 19-litre AdBlue tank will need a top-up.

At half load, however, the manoeuvrable ‘120’ uses hardly any AdBlue. Exhaust gas after-treatment is carried out with the hat trick of a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and the SCR. Here a sensor that checks AdBlue quality caused the first unscheduled visit to the workshop after 566 hours.

Up front, the compact radiator pack under the sloping bonnet is stretched to its limits when mowing. Especially in hot summer temperatures, operators need to adapt how they drive to ensure the temperature gauge stays in the green. The sloping bonnet also means that access to the cooling pack is limited. The four radiators don’t unfold, and the removable screens on other John Deeres are noticeably absent on the 6120M. The optional reversible fan would have been a sensible option here.

Speaking of the bonnet, at around 2,850 hours, the shear grab was used to take some maize from the 6.0m high clamp in a rather ‘sporty’ style. A large lump of silage landed on the plastic bonnet, where slight cracks are still visible, but this was clearly no fault of the manufacturer. However, the not so durable bonnet stickers certainly are. Above all, the driver’s view to the front of the loader or front-mounted implements is refreshingly clear.

Stepless = problem-free

Three years ago, the farmer opted for the continuously variable AutoPowr transmission with a maximum speed of 40km/hr. The ZF-Eccom with four travel ranges is excellent in practice: the overall controllability, driving comfort, quick direction changes and the engine-gearbox control have all satisfied the farmer. Its operation with the “magic wand” and dial is also easy to understand, even for temporary drivers.

As the transmission and hydraulics share the same oil reservoir, timely oil changes (53 litres every 1,500 hours) are a priority for this farmer, especially when the tractor is used with multiple implements that are shared with other tractors … so oil cross contamination is obviously a risk.

Lots of oil, not enough connectors

Because the owner was always going to operate the 6M with a front loader (Quicke Q5M), he plumped for the larger variable displacement pump option with 115l/min. This means that the 6M has sufficient oil capacity for fast loading cycles. After 3,182 hours, the oil pressure from the axial piston pump suddenly failed. The manufacturer and dealer were accommodating with the repair, which cost €3,750. The new pump has been reliably doing its job ever since.

With regard to spools, only three electric spools at the rear were not enough at times, not helped by using one for the hydraulic top link. Three extra spools were plumbed to the rear from the mid-mounts and from the front linkage by inserting tees — but drivers must be aware of this. So far there have been no problems with these hoses, although they are tightly packed and are starting to rub.

Thanks to the additional oil tank, the 32 litres of oil that can be removed are enough for tipping 16t trailers.

The Quicke loader itself has clocked more hours than the tractor, because it is shared between the other tractors on the farm (a 6125R and older 6330). The 2.20m wide grab bucket is used daily, feeding/loading silage from the clamp. This high workload resulted in the loader boom crack at the lower pivot when the tractor had reached 4,350 hours. In fairness to Quicke, it was very accommodating and recommended the next model up, the Q6M, which now shares the work with the smaller boom.

Despite the many hours of loader work, there have been no problems with the front axle and suspension. It is understandable that the original front tyres (540/65 R24) are now worn. At the rear, a loose dual wheel clamp pierced one of the back tyres (4,300hr). This prompted the fitment of new 600/65 R38 tyres.

The tractor’s mechanical cab suspension in conjunction with the cosseting front axle suspension receives good marks. Driving comfort when on road work isn’t a problem even with a wheelbase of just 2.40 metres. The dynamic front mudguard brackets did need replacing after 4,500 hours, with the retrofit kit costing €945.

As for the linkages, we’ll keep it short and sweet: with the optional larger assister rams that boost the lift capacity to 4.3t, there isn’t an implement in the yard that it can’t handle, and the lift geometry ticks the box, too. On the other side of the coin, so to speak, there isn’t enough room for the automatic stabiliser on the right as the auxiliary (donut) oil tank sticks out, thus filling the space behind the wheel rim. So, this is not an option for tractors with the extra tank.

A Sauter front linkage was fitted because the farmer liked the look of it. There are no criticism in terms of lifting power. The front pto is engaged hydraulically. Intriguingly, a spare V-belt was left in situ when the front pto was installed but this was unfortunately damaged by rubbing against the bonnet, so it had to be discarded. But, even after 4,600 hours, the original belt is still working fine.

Small but beautiful cab

The cab of the relatively compact 6M is certainly not as roomy as some others in this power bracket. And climbing into the six-post cab is tight. But once you’re seated, everything is in its place and the cab is nice and quiet. After 1,342 hours, a broken cable on the seat compressor led to a real ‘low’ for the driver.

The CommandArm armrest in the “premium version” is a good fit, and the front loader joystick is perfectly positioned. The farmer has become just as accustomed to the hand contact pad on the joystick as to the shuttle control on the front loader joystick. This said, the newer John Deere joysticks are more ergonomical.

A 4640 terminal was retrofitted for the SF1 steering system. This means that fields can also be saved and not just AB lines, which was the limitation of the standard-fit corner post display autosteer system.

The pillar display shows the most important tractor information, but the layout is too small when adjusting settings. However, programming the auto headland control is largely eliminated on our 6M, as it has been optionally equipped with iTec-Basic. This dis/engages four-wheel drive, diff lock and pto relative to linkage position. If you want to program in more functions it would be worth looking towards the 6R. The little Deere gets top marks for its LED lights. Although the cab may seem small, it offers enough space to fit work lights for all-round illumination.

The bright interior is just as pleasing to users as the overall finish and quality. You can almost ignore a few grease stains on and around the radio, especially as the floor and armrest are very easy to clean. Minor niggles are a bulging rubber seal on the windscreen and stiff door lock, details that are not very annoying on your day-to-day chores.

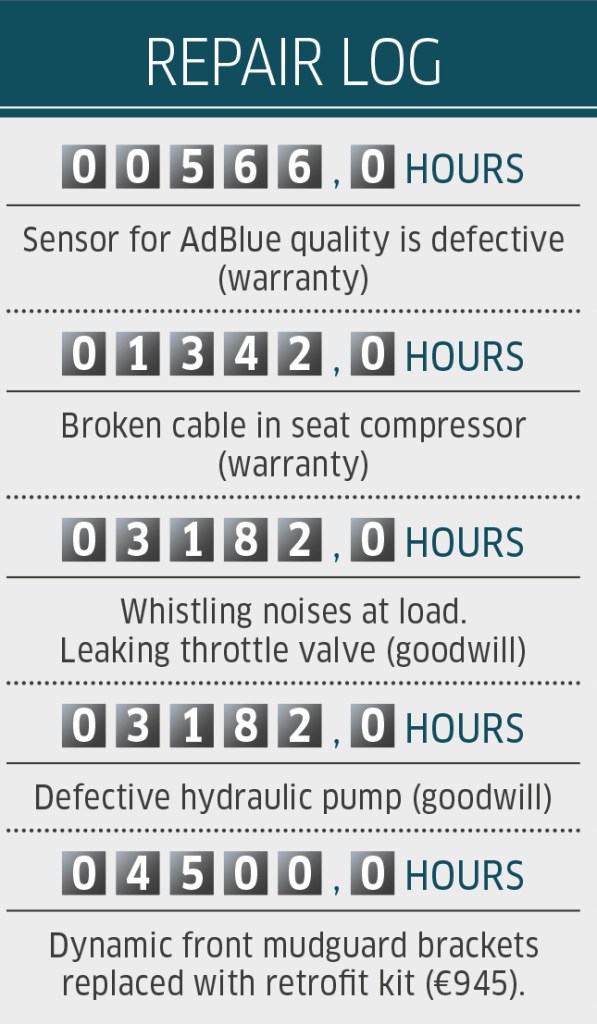

The maintenance costs for the 6M, excluding labour costs, are only €1.91 per operating hour including VAT. Since the warranty period has now expired, the farmer has been changing the oil and filters himself … and he’ll continue to adopt this policy.

USER EXPERIENCE

Reliable and compact

Our long-term test 6120M is used by German farmer Christoph Rülfing. The farm keeps 250 cows plus youngstock and grows fodder on approximately 150 hectares of land.

“We do most of the outside fieldwork ourselves; the only thing we don’t have is a forage harvester,” says the 45-year-old farmer, when describing his business. “We opted for the 6M at the time because we were looking for a loader tractor. We also considered a telescopic wheel loader, but we didn’t think we had enough work for one.

With the 6M, we can perform many additional tasks in addition to the loader workload. This increases utilisation and reduces costs, even if the loader has already had to be replaced,” says Christoph, who remains convinced he made the right choice.

When asked about the four cylinders: “There’s a kind of four-cylinder mafia on our farm,” he jokes. “My part-time staff and employees are just as convinced as I am. The next tractor will be a 6R150. Power delivery and diesel consumption are in no way inferior to the six-cylinder models. And I need very manoeuvrable tractors on my farm,” adds Christoph.

Summary

The 6120M has been a loyal servant on the dairy farm for more than 4,600 hours. Apart from the defective hydraulic pump, the entries in the number of listed repairs are not too bad. The manoeuvrable front loader tractor scores with its comfort and punchy performance. However, the cooling capacity at full load and the small fuel tank are criticised. To be fair, John Deere offers solutions for these two issues — you just have to pay a little extra to access them.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.