WORKSHOP: In profi 9/2023 we looked at universal joints and guards. This article deals with maintaining cam clutches, overrun clutches and heads as well as replacing spline shafts.

To protect implements from sudden overload, a variety of clutches can be installed to cut the power when a certain torque is reached. These include, for example:

● Cam clutches

● Star ratchet clutches

● Shear pin clutches

● Friction clutches

● Rotary play clutches

● Freewheel clutches

A cam clutch consists of four spring-loaded cams that engage in cut-aways to transmit the torque. If the torque acting on the springs exceeds their tension, the cams will deflect and no longer transmit the power. Once the reason for the excess torque has been removed, the cams automatically re-engage at reduced speed. Due to the special form of its cams, this type of clutch rotates only in the one direction. This must be borne in mind when replacing the entire clutch or when ordering individual parts.

Checking the clutch

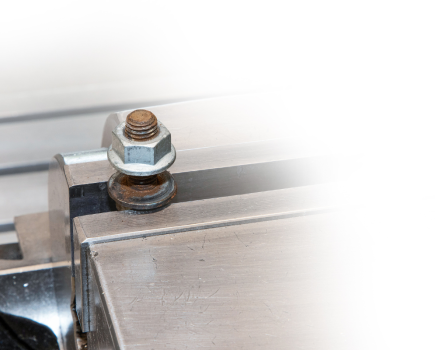

A test stand is used to verify the tripping torque of an overload clutch. Our photos were taken on the test stand of machinery dealership Landtechnik Möckern. Without a test bench, you can carry out only a visual inspection of the edges and cams. Inspect whether these are heavily damaged or rounded. A cam clutch that disengages for too long is at risk of overheating. The long term effect of this is that the cams seize up, because the grease will leak away and the housing begins to corrode.

For more up-to-date farming news click here and subscribe now to profi and save 47%.