PRACTIAL TEST: Once you’ve used a cordless impact wrench, it’s hard to imagine not having one readily to hand in the farm workshop. But which is best? We compared six high-end, cordless impact wrenches with a ½-inch square drive to find out.

Cordless impact wrenches belong to the basic tool inventory of a farm workshop. These cordless units are very convenient for use in the field, for replacing worn cultivator metal or even new flails on a mower. But will they also loosen an M8 screw on a panel? Yes, possibly. So, we asked a bunch of manufacturers to send us their most powerful model with a ½-inch square anvil.

Since the Makita TW008G wasn’t of the same size and power as the other test candidates, the firm delivered another wrench with a ¾-inch square anvil, the TW001G. We tested this one outside the ½-inch comparison. With the exception of the Makita (40-volt system), all tools are operated with 18 volts.

How the tests were carried out

First, we tested the tools in practical use with the focus on handling, setting options and responsiveness in operation. Our testers also measured the battery capacities. To do this, we operated a rotating metal paddle in a water-filled barrel. This test offered so much resistance that the impact unit of all the wrenches triggered easily. We operated each wrench in 30 second cycles until the battery was empty. Each wrench was paused for 30 seconds between cycles.

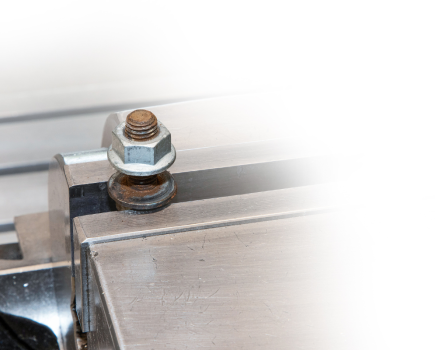

In order to determine the tightening and loosening torques in a setting as realistically as possible, we made a test stand where we screwed a nut onto a 20cm M24 bolt (SW36). Secondly, we carried out tightening tests on an M22 wheel bolt (SW32). The exact position of the nut after it was tightened with the wrench was marked with a pointer.

For more up-to-date farming news click here and subscribe now to profi and save 47%.